Aluminium manufacturer AlumPort

Up to 350 tons of aluminum per month passes through our hands. We comply with the technology and have been working without defects since 2011.

Our history

We started working with aluminum profiles in 1997 and became one of the largest profile importers for sliding wardrobes from China.

In 2011 we launched our own aluminum plant - AlumPort

The main goal of plant building is independence from the prices of the imported profile and work according to international quality standards that exceed GOSTs (State Standarts).

What we are proud of:

> Wheels for the 16t time winners of Paris Dakar Rally - Protective coating application onto the wheels of KAMAZ MASTER team

> Profile manufacture for the entrance group and the ladder in Georgievsky hall of the Moscow Kremlin

> Anodizing of facade profiles during the reconstruction of Paveletsky railway station in Moscow - 2000 square metres in 10 days

> Making decorative fence to the Ivanovskaya Kremlin square - quality requirements of our coating are higher than the state standards

Tasks that we solve:

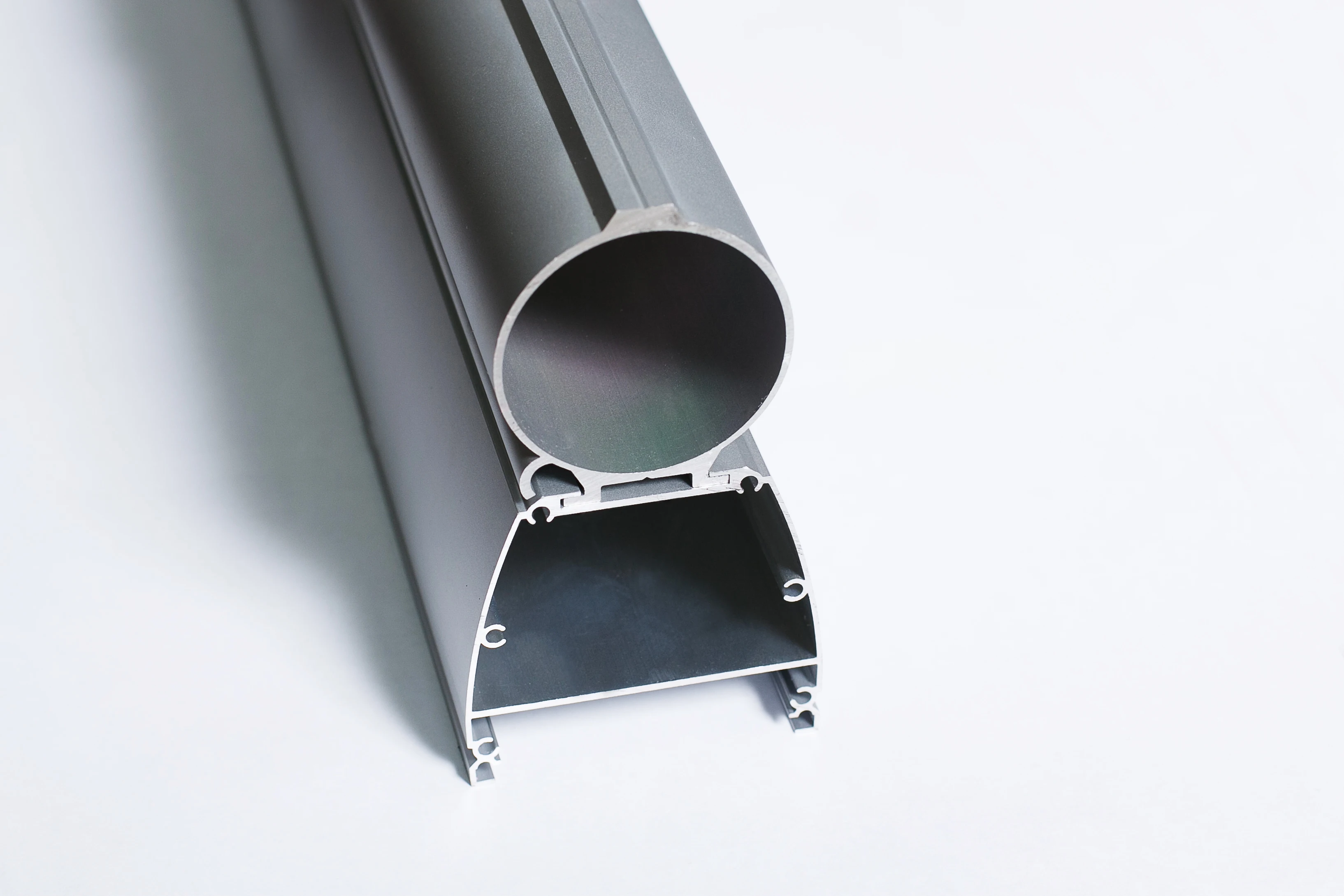

✔ We prepare a profile drawing when the client has only a sketch.

✔ We select the desired metal alloy, the state of hardening and aging.

✔ We develop equipment for the aluminum extrusion, taking into account the high requirements for the front product side.

✔ We control the aluminum profiles manufacture, excluding any defects.

✔ We finish the surface. We grind, polish, brush, anodize and paint.

✔ We do processing on CNC machines. We mill, drill, saw and do radius bending.

Our true strength is aluminum anodizing

We have developed 73 basic anodizing recipes and are ready to make a unique recipe for the client's tasks.

We work only with wholesale customers

The minimum order is 500 kg of profile.

If you need a test sample, we will manufacture it on a 3D printer.

Our partners and customers: