Product Description

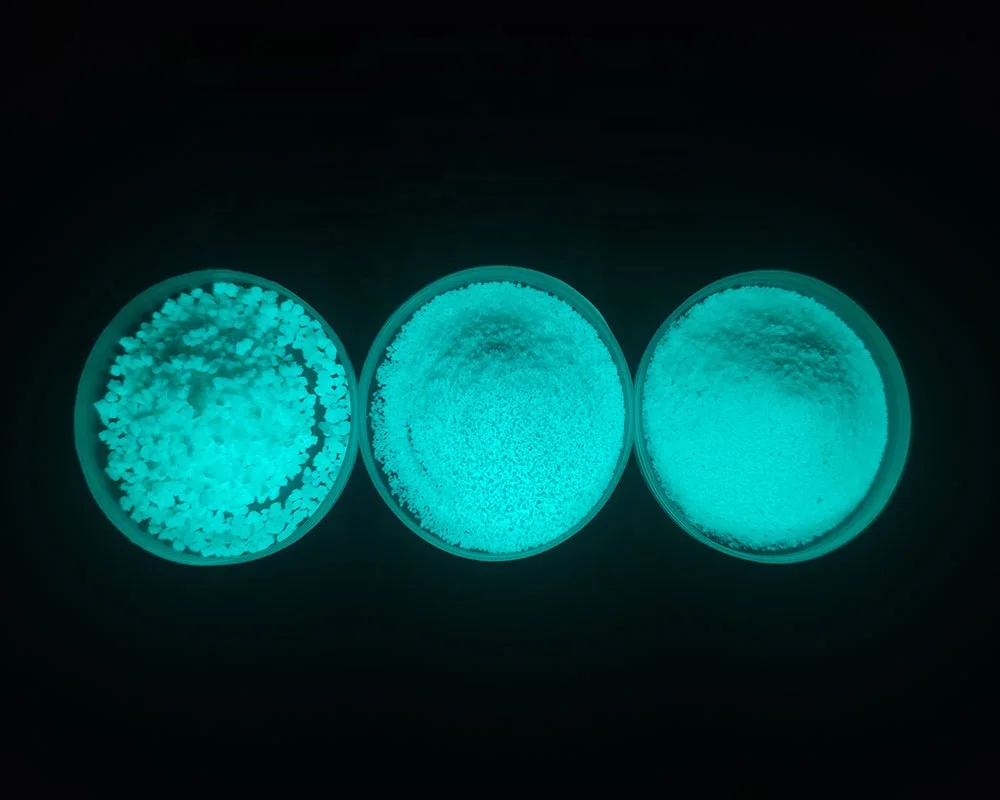

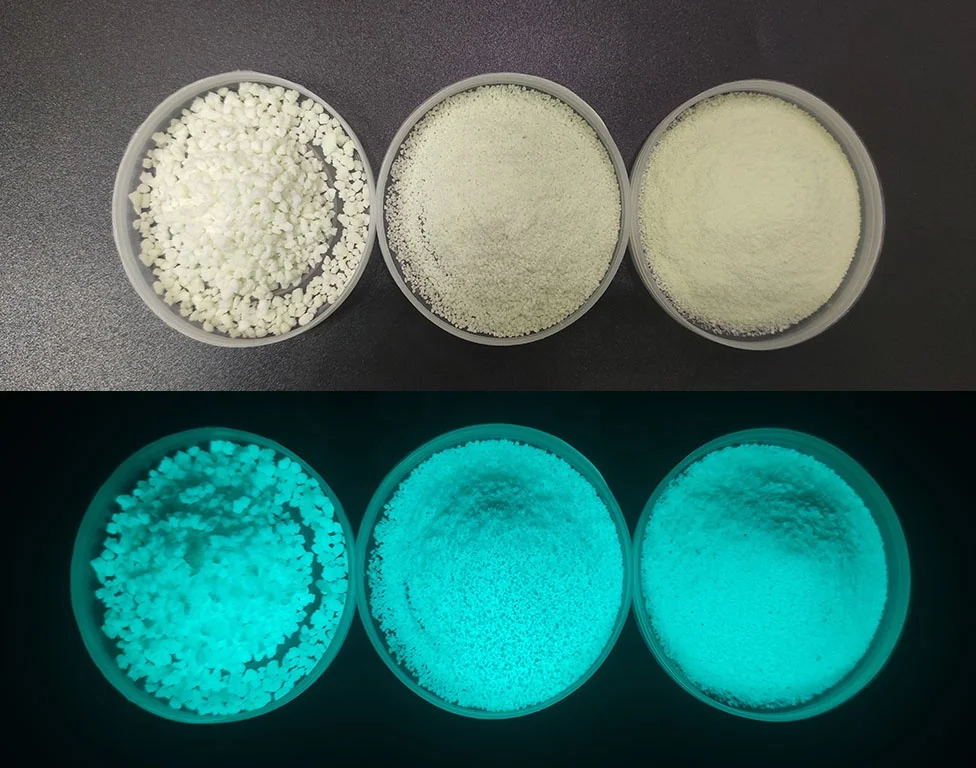

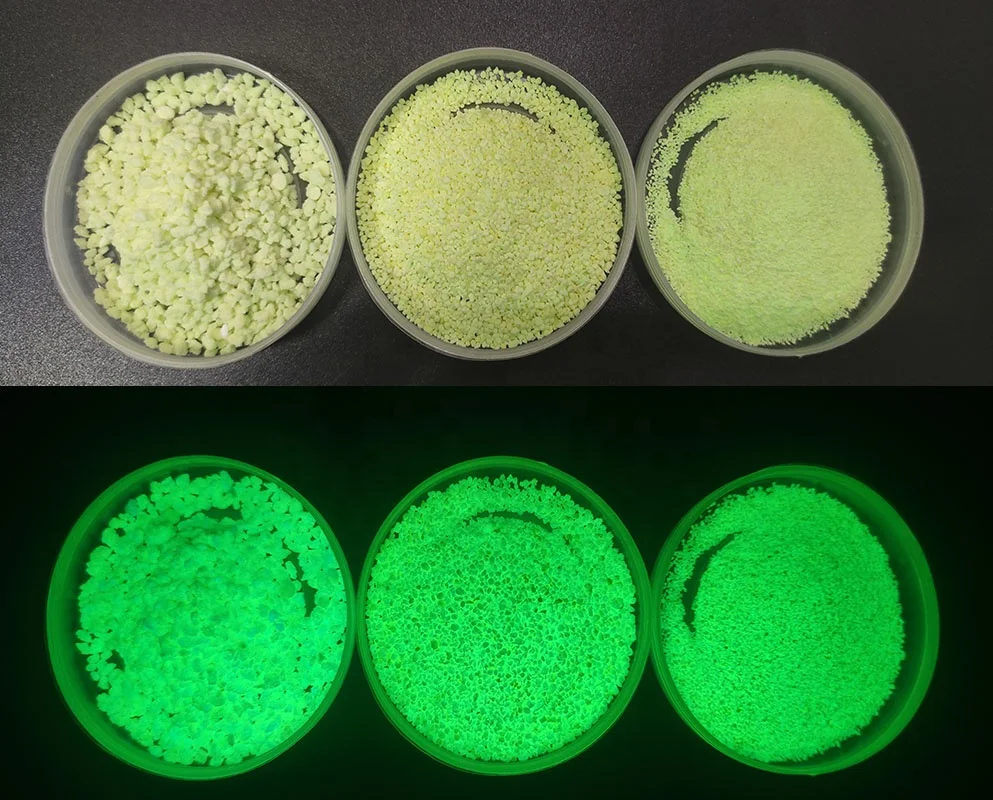

Model: | SLB-20 | Size: | 20 mesh |

Material: | Strontium aluminate | Brightness: | 1min-3611,10min-498,60min-69 |

Glowing color: | Blue Green | Life time: | More than 15 years |

Luminous powder use for Mosaic:

Usually there are two ways of applying glow in the dark powder to glass mosaic, cold spraying and hot melt process.

Cold spraying:

is the relatively simple one. Cold spraying: First, Mix the glow in the dark particle with ink evenly and keep the proportion of the particle about 20%-50%. Avoid contacting with iron products when mixing. After that spray the mixture on the glass surface for generally 2-3 times. Better to keep stirring the mixture to make sure that it is evenly sprayed on the surface. It can avoid that some ink with little glow in the dark particle would be sprayed.

Hot melt process:

Hot melt process is more complex. It is usually use screen printing. First, mix the glow in the dark particle with ink evenly,also keep the proportion of the particle about 20%-50%. Do not use any iron products, too. Use the screen of 80 mesh to print the mixture on the back of the glass for 2-3 times. Then seal the surface with a white layer to enhance its performance. Last, firing.

In the firing process, lower the temperature as possible, no more than 800 degrees centigrade.

is the relatively simple one. Cold spraying: First, Mix the glow in the dark particle with ink evenly and keep the proportion of the particle about 20%-50%. Avoid contacting with iron products when mixing. After that spray the mixture on the glass surface for generally 2-3 times. Better to keep stirring the mixture to make sure that it is evenly sprayed on the surface. It can avoid that some ink with little glow in the dark particle would be sprayed.

Hot melt process:

Hot melt process is more complex. It is usually use screen printing. First, mix the glow in the dark particle with ink evenly,also keep the proportion of the particle about 20%-50%. Do not use any iron products, too. Use the screen of 80 mesh to print the mixture on the back of the glass for 2-3 times. Then seal the surface with a white layer to enhance its performance. Last, firing.

In the firing process, lower the temperature as possible, no more than 800 degrees centigrade.

Customer Photos

Packing & Delivery

We can support customized package service according to your requirement,such as 50g/bag,100g/bag,1kg/bag,5kg/bag or 25kg/durm.

Quantity | Shipping term | Shiping time | Courier |

Less 2 kg | By express with tax | 7 days or 25 days | HK EMS |

2 kg-100kg | By express without tax | About 10 days | Fedex, DHL |

100kg-500kg | By express or common air or sea | 7 days or 15 days or 35 days | Fedex, DHL, COSCO,KINLINE.etc |

More 500kg | By express or common air or sea | 7 days or 15 days or 35 days | Fedex, DHL, COSCO,KINLINE.etc |

Certification

Our Service

1.We will provide free service on 24 hours.

2.We can offer 200G sample for free,you can choose any colors and models,you only need to pay the frieght.

3.We have a complete QC system , and regulary the quality on 24hours.

4.We have a specialized foreign trade team , and can provide you the professioanl service .

5.We have several sets of the production equipments , can meet your delivery time in time .

6.We are factory , and can provide the cheap price for you . And have our own production line .

7.Keep delivery time with our best after-sales service for you .

8.Professional shipping deparment can provide safety and convenience service for you .

If you are interested in our products,welcome to contact us below:

Phone/Whatsapp/Skype:+86 13790064379

Email:oklab88@163.com