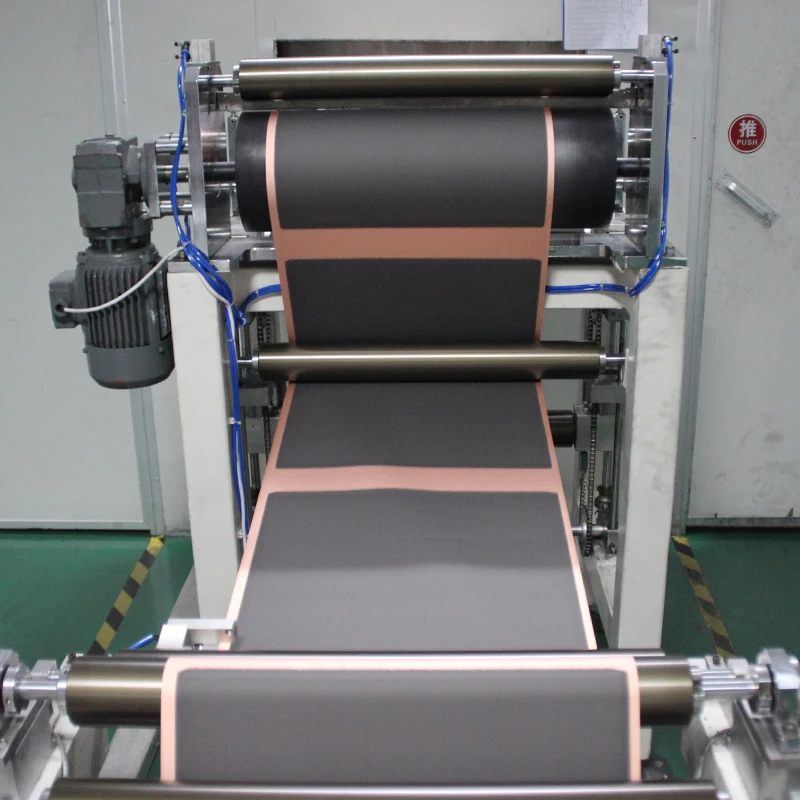

Intermittent Transfer Battery Electrode Coating Machine Coater for EV Electric Vehicle Power Lithium Battery Making Machine

Product Overview

For battery electrode coating ,can be intermittent coating and continuous coating process .

Coating process :

The substrate placed on the unwinding device is automatically corrected and then enters the

floating roll tension system, and the unwinding tension is adjusted to enter the coating head, and the slurry is coated according to the setting procedure of the coating system. The coated wet electrode enters the oven and is dried by hot air. Then the dried electrode is tensioned by a tensioning system while controlling the winding speed to synchronize it with the coating speed. The electrode is automatically corrected by the correcting system to maintain it in the center position, and is wound up by the winding device.

floating roll tension system, and the unwinding tension is adjusted to enter the coating head, and the slurry is coated according to the setting procedure of the coating system. The coated wet electrode enters the oven and is dried by hot air. Then the dried electrode is tensioned by a tensioning system while controlling the winding speed to synchronize it with the coating speed. The electrode is automatically corrected by the correcting system to maintain it in the center position, and is wound up by the winding device.

The coating machine includes the following parts:

1. Unwinding mechanism (active unwinding)

2. Coating floating roller tension mechanism

3. Coating mechanism

4. drying system (three sections of drying area)

5. the collection mechanism

6. winding mechanism

7. Coating drying automatic control system

PRODUCT SPECIFICATIONS

Equipment specifications:

1, Substrate thickness: aluminum foil: 0.012--0.030mm copper foil: 0.008-0.030mm

2, Substrate width:aluminum foil:100—360mm copper foil:100—360mm

3, the maximum coating wet thickness:80--400µm (under the viscosity of the slurry allows)

4, the maximum coating width: 300mm,the maximum roller width:360mm

5, Mechanical traveling speed: 0.5-7M/min (maximum speed)

6, Coating speed: 0.5—1.5M/min

7, Total length of the machine: 1.5 m × 3 section oven = 4.5 m

Equipment performance:

1, coating method: Transferred intermittent coating

Intermittent coating distance: 5-8000mm ± 1mm (according to battery specifications).

2, coating accuracy:

2.1. Dry thickness accuracy error: single-sided cathode: ±2.5μm anode ±2.5μm (cross-section measurement 4-5 points, vertical section measurement spacing is 100mm).

2.2, the front and back coating alignment error: ≤ ± 1.0mm

2.3, average length error: ≤ ± 1.0mm

2.4, average width error: ≤ ± 1.0mm

3, core diameter: 3 inches with air shaft

4, tension control: sprocket tension, counterweight constant tension

5, Correction controller accuracy: ±0.01mm; Correction accuracy: ±1mm

6, the operator operates the coating mechanism from the front

7, drying form:

7.1. hot air drying: hot air circulation (upper air supply);

7.2. Heating method: electric heating 6KW × 3 segments = 18KW;

7.3.heater;

8, oven length: 1.5M / section × 3 section (total 4.5M),other length can be customized

9, oven material: both inside and outside are made of stainless steel

10, oven temperature: room temperature - 150 ° C, two section can be independently adjustable, temperature control accuracy < ± 5° C;

1, Substrate thickness: aluminum foil: 0.012--0.030mm copper foil: 0.008-0.030mm

2, Substrate width:aluminum foil:100—360mm copper foil:100—360mm

3, the maximum coating wet thickness:80--400µm (under the viscosity of the slurry allows)

4, the maximum coating width: 300mm,the maximum roller width:360mm

5, Mechanical traveling speed: 0.5-7M/min (maximum speed)

6, Coating speed: 0.5—1.5M/min

7, Total length of the machine: 1.5 m × 3 section oven = 4.5 m

Equipment performance:

1, coating method: Transferred intermittent coating

Intermittent coating distance: 5-8000mm ± 1mm (according to battery specifications).

2, coating accuracy:

2.1. Dry thickness accuracy error: single-sided cathode: ±2.5μm anode ±2.5μm (cross-section measurement 4-5 points, vertical section measurement spacing is 100mm).

2.2, the front and back coating alignment error: ≤ ± 1.0mm

2.3, average length error: ≤ ± 1.0mm

2.4, average width error: ≤ ± 1.0mm

3, core diameter: 3 inches with air shaft

4, tension control: sprocket tension, counterweight constant tension

5, Correction controller accuracy: ±0.01mm; Correction accuracy: ±1mm

6, the operator operates the coating mechanism from the front

7, drying form:

7.1. hot air drying: hot air circulation (upper air supply);

7.2. Heating method: electric heating 6KW × 3 segments = 18KW;

7.3.heater;

8, oven length: 1.5M / section × 3 section (total 4.5M),other length can be customized

9, oven material: both inside and outside are made of stainless steel

10, oven temperature: room temperature - 150 ° C, two section can be independently adjustable, temperature control accuracy < ± 5° C;

Company Profile

Successful Project

Our Factory

FAQ

Contact Us