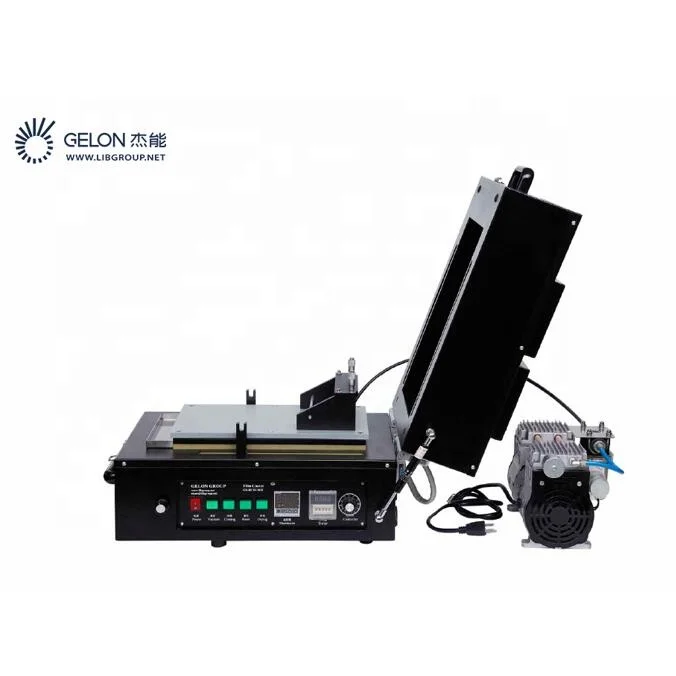

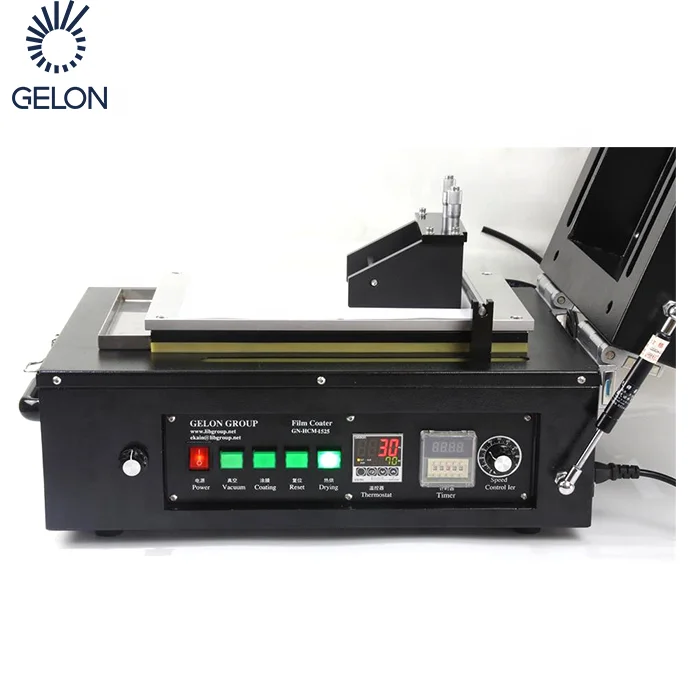

GN-VC-10H automatic coater is designed to produce consistent thick film with heating cover. It hasa unique driving system to produce smooth coating on all types of materials. The flat vacuumchuck is built in to hold substrate sheet on plate faster and easy, which is particularly useful whencoating on thin substrate and make uniform tape casting. One 100 mm width micrometeradjustable applicator is included for immediate use. Heating cover with digital temperaturecontroller can dry film after coating up to 200°C within +/-1°C. This machine is being used forresearch for ceramic tap casting and Li-Ion battery electrode coating.

Technical parameter:

|

Main technical parameters |

Automatic coating dry machine |

|

Source voltage |

AC 220V/110V, 50HZ |

|

Power |

650W |

|

Coating speed |

0-100mm/s, Step-less transmission |

|

Max coating size |

100mm*250mm |

|

Vacuum board material |

Aluminum alloy |

|

Vacuum board size(L*W*H) |

365*200*30mm |

|

Slicker adjustable range |

0.01-3.5mm |

|

Slicker width |

0-100mm |

|

Heating dry system |

RT-200°C, Digital temperature controller |

|

Temperature control accuracy |

1°C |

|

Vacuum Pump |

Oil-less vacuum pump |

|

Dimension(L*W*H) |

500*310*330mm |

|

Weight |

About 65kg |

Product photoes:

1 Standard exported package : Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way,

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

We are the first and earliest exporter for Li-ion battery materials. We focus on lithium electricity industry for 20 years, can provide full set of lithium battery materials ,equipment and technology. We can provide one-stop solution for you, provide a "turn key" project for you!

We can supply full set of lithium ion battery materials and equipments.

1.)full set of lithium battery materials, including :

LiMn2O4,LTO,LiNiMnCoO2(NMC),LiCoO2,Graphite(MCMB)and other cathode&anode battery materials; Aluminum foil, copper foils, battery separator, etc.

2.)full set of lithium battery equipments ,for example:

mixing machine --coating machine--oven--rolling machine--welding machine--slitting / cutting machine --winding machine--sealed machine, etc.

3.)full set of lithium battery technology

we can design the laboratory and production line,according to customer's request.