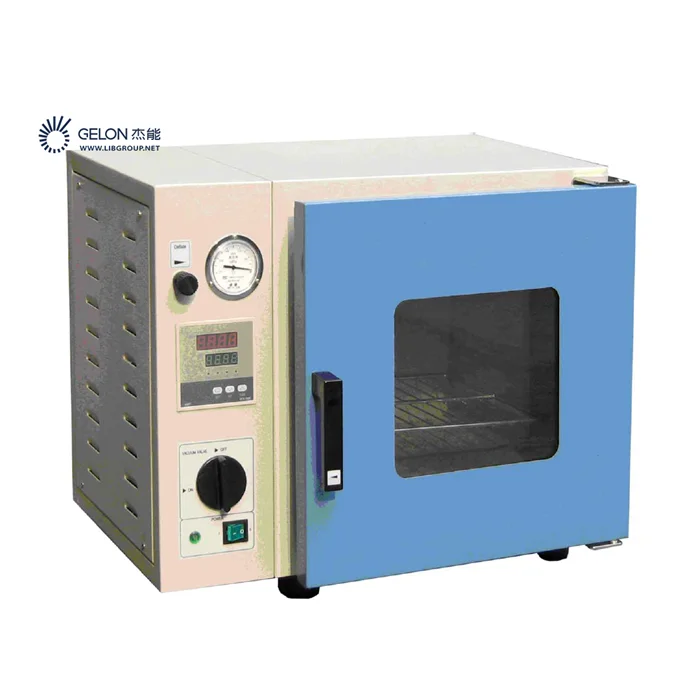

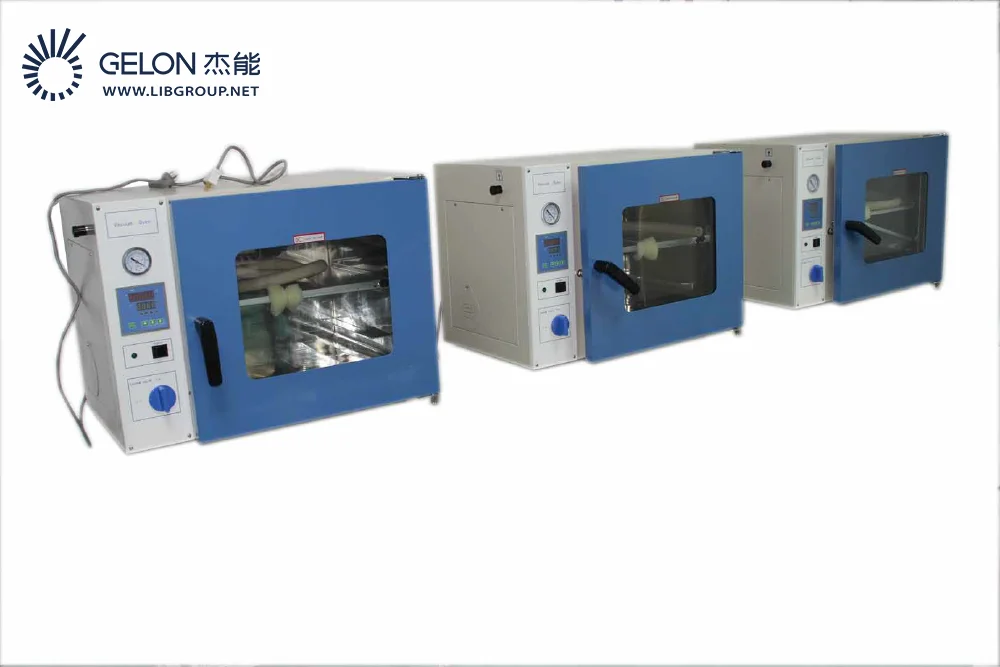

Lithium Battery Vacuum Oven for Battery Lab Equipment

1.Radiant warm wall heating system provides optimal uniformity and conserves chamber space for drying, curing, vacuum embedding, and plating applications.

2.52 L Middle size vacuum chamber.

3.3" (7.6 cm) glass wool insulation prevents heat loss from working chamber.

4.Silicone door gasket and positive latch door maintain seal at all vacuum levels.

5.Exclusive polycarbonate safety shield protects door glass.

6.Vacuum fittings require .25" (6.35 mm) I.D. tubing.

7.Easy-to-clean #304 stainless steel chamber interior.

8.Vacuum and air lines constructed with corrosion-resistant stainless steel tubing for optimum chamber cleanliness and long term performance.

9.Two removable stacking aluminum shelves included.

SPECIFICATION FOR LITHIUM BATTERY VACUUM OVEN | ||

Power supply | 220/110v AC, 50/60HZ | |

Power | <1500W, 10A Max | |

Inner chamer size | 415*345*370mm | |

Outside size | 710*560*550mm | |

Vacuum | <133pa | |

Shipping weight | 90kgs | |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

*Normal machine is properly adjusted before dispatch.

*You will be able to get free training advice towards our machine in our factory.

* You will get free suggestion consulting technical support and service by email and lifetime technical support.

1.)full set of lithium battery materials,including :

LiMn2O4,LTO,LiNiMnCoO2(NMC),LiCoO2,Graphite(MCMB)and other cathode&anode battery materials;Alumimun foil,copper foils,battery

separator,etc.

2.)full set of lithium battery equipments,for example:

Mixing machine --coating machine--oven--rolling machine--welding machine--slitting / cutiing machine --winding machine--sealed

machine,etc.

3.)full set of lithium battery technology:

We can design the laboratory and production line,according to customer's request.