1. Correction accuracy :05mm

2. Separator width:≤200mm

3. Maximum separatorroll:φ250mm;

4. Applicable electrode specification :L(100-200)mm, W(90-200)mm,H:4-12mm;

5. Tab length:≤30mm

6. Swing roll travel:400mm;

7. Power:AC220V/50Hz;

8. Air pressure source:5MPa~0.7MPa;

9. Size:L465mm×W585mm×H540mm;

10. Weight:30Kg

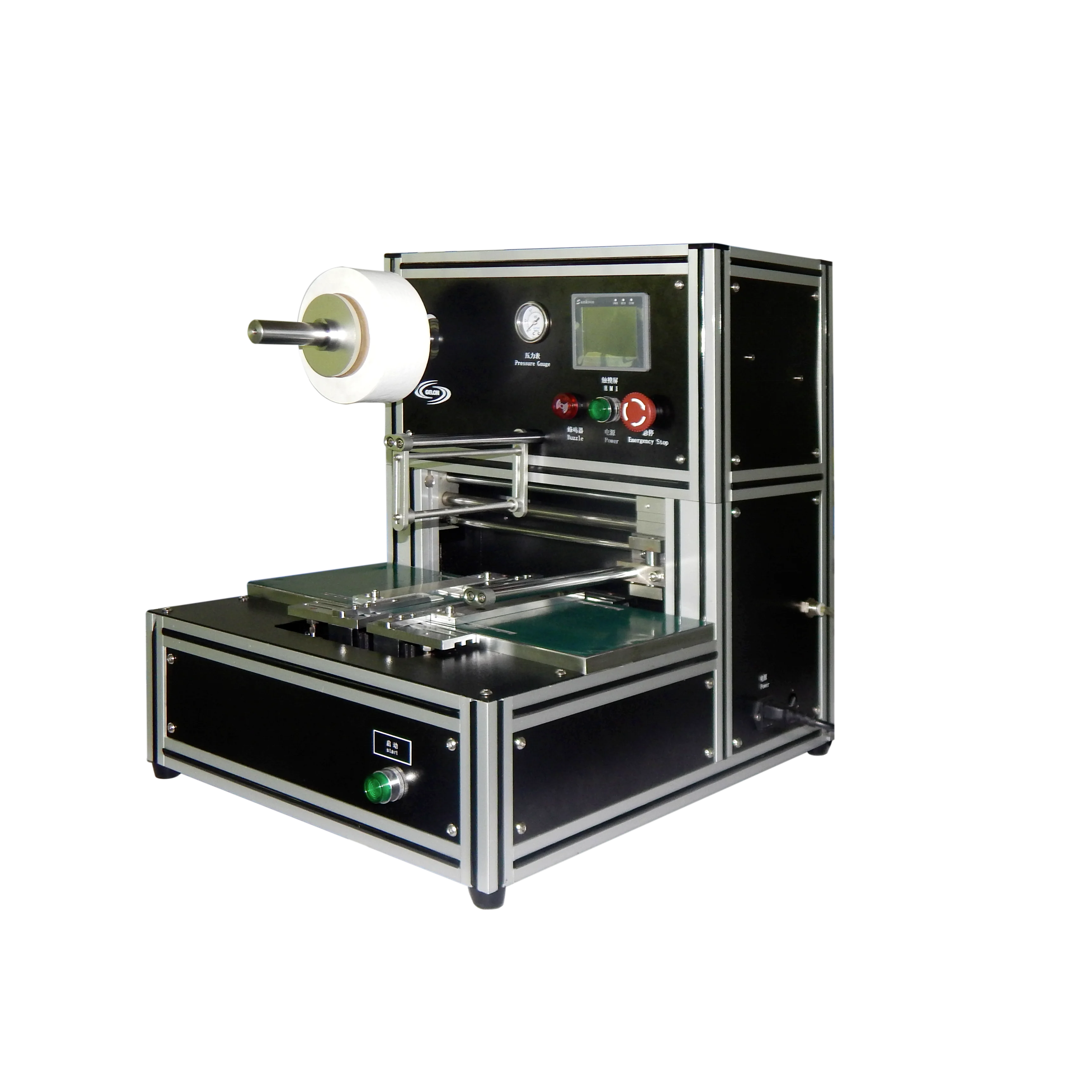

Product Description

Working principle

This equipment is suitable for stacking process of lithium ion battery electrode. The equipment is designed with tension roller structure. Rolled isolation film is automatic constant tension controlled. It realizes Z-shaped laminated sheet by moving left and right by Motor, so that the stacking assembly of the whole electric core is realized in a reciprocating way. Separator feeding adopt constant tension, and electrode automatic correction function is arranged in the feeding process. The feeding process is neat and consistent.It has the feature of high efficiency of sacking and high precision of stacking. The size of different electrodes can be realized by adjusting the clamp. It is suitable for the research and development of stacking lithium ion battery and sample making.

Specification

Battery tab direction

Size Information

Main parameters:

Correction accuracy | Separator width | Maximum separator roll | Applicable electrode specification | Tab length |

0.05mm | ≤200mm | φ250mm | L(100-200)mm, W(90-200)mm, H:4-12mm | ≤30mm |

Swing roll travel | Power | Air pressure source | Size | Weight |

400mm | AC220V/50Hz | 0.5MPa~0.7MPa | L465mm×W585mm×H540mm | 30Kg |

Related Products

Packing&Shipping

Package

Exporting wooden package

Shipping

We can support the shipment by Express, DHL, FEDEX, TNT, EMS...

By air

By sea

After Sales Service

Company Introduction

Our Services & Strength

1.)full set of lithium battery materials,including :

LiMn2O4,LTO,LiNiMnCoO2(NMC),LiCoO2,Graphite(MCMB)and other cathode&anode battery materials;Alumimun foil,copper foils,battery

separator,etc.

2.)full set of lithium battery equipments,for example:

mixing machine --coating machine--oven--rolling machine--welding machine--slitting / cutiing machine --winding machine--sealed

machine,etc.

3)full set of lithium battery technology.

we can design the laboratory and production line,according to customer's request.

LiMn2O4,LTO,LiNiMnCoO2(NMC),LiCoO2,Graphite(MCMB)and other cathode&anode battery materials;Alumimun foil,copper foils,battery

separator,etc.

2.)full set of lithium battery equipments,for example:

mixing machine --coating machine--oven--rolling machine--welding machine--slitting / cutiing machine --winding machine--sealed

machine,etc.

3)full set of lithium battery technology.

we can design the laboratory and production line,according to customer's request.

FAQ