The machine has a diaphragm correction, anti-bending multi-piece electrode piece, the material cabinet automatically ion wind blow

(let electrode drifted away to prevent double sheet), the secondary function of the position table blowing dust.

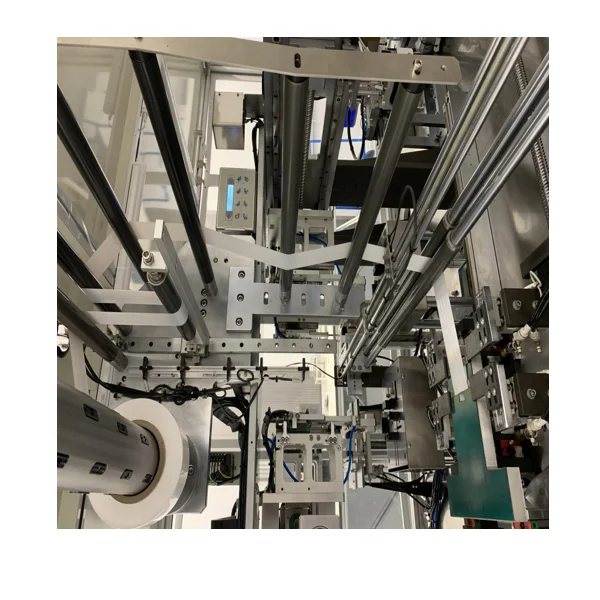

Product Description

This machine is designed for large square lithium-ion battery, use Z-shaped stacking method. The machine through four manipulator to take the cathode and anode electrodes from the material cabinet to the position taken place on the second platform, after framing station and then placed on the stacking platform, it is with automatic clamping device.

Model | GN-DP300S |

Suitable battery core specs | 0~20mm thickness |

Suitable battery core specs | 150~200mm width |

Suitable battery core specs | 250~300mm length |

Tabs length(mm) | Q≤30 |

Tem\humidity | 5-45℃; 5-65% |

Compressed air | pressure 0.5-0.7Mpa |

Single piece efficiency | 2~2.5s/pcs |

Ingle cell making time | 20S-40S |

stacking core width | Min: anode electrode +0.6mm 、 Max: anode width+1.3mm |

Battery core thickness | ≤20 |

Fixture | Suitable the single side tab |

Diaphragm constant tension control device, the diaphragm correction device, cathode and anode film transfer device, the cathode

and anode anti-bending electrode multi-piece unit, the positive and negative secondary alignment device, the ion wind blowing pod

device, the second to blow the dust removal device-bit platform, positive and negative film lifting device, batteries clamping

device, the diaphragm cutting device, the diaphragm recovery, membrane recycling corrective devices, batteries tail winding

device, batteries transfer device .

and anode anti-bending electrode multi-piece unit, the positive and negative secondary alignment device, the ion wind blowing pod

device, the second to blow the dust removal device-bit platform, positive and negative film lifting device, batteries clamping

device, the diaphragm cutting device, the diaphragm recovery, membrane recycling corrective devices, batteries tail winding

device, batteries transfer device .

Packing&Shipping

1 Standard exported package : Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way,

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way,

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Related Products

Semi-auto stacking machine

91.8% Response Rate

Battery separator

91.8% Response Rate

Manual stacking machine

91.8% Response Rate

We can supply full set of lithium ion battery materials and equipments.

1.)full set of lithium battery materials, including :

LiMn2O4,LTO,LiNiMnCoO2(NMC),LiCoO2,Graphite(MCMB)and other cathode&anode battery materials; Aluminum foil, copper foils, battery separator, etc.

2.)full set of lithium battery equipments ,for example:

mixing machine --coating machine--oven--rolling machine--welding machine--slitting / cutting machine --winding machine--sealed machine, etc.

3.)full set of lithium battery technology

we can design the laboratory and production line,according to customer's request.

1.)full set of lithium battery materials, including :

LiMn2O4,LTO,LiNiMnCoO2(NMC),LiCoO2,Graphite(MCMB)and other cathode&anode battery materials; Aluminum foil, copper foils, battery separator, etc.

2.)full set of lithium battery equipments ,for example:

mixing machine --coating machine--oven--rolling machine--welding machine--slitting / cutting machine --winding machine--sealed machine, etc.

3.)full set of lithium battery technology

we can design the laboratory and production line,according to customer's request.

Our Company

We can provide full set of lithium battery materials ,equipment and technology. We can provide one-stop solution for you, provide a "turn-key" project for you!

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Our Team

Why Choose Us

FAQ