BEIMAN T5/T8/T10/T12 LED light tube extruder machine 2 colors co-extrusion diffuser pc cover profile making machine i

This production line is mainly used to produce PC fluorescent tubes, LED lamp (LED fluorescent tubes), PC tube, transparent double-color tube, grind arenaceous pipe and fluorescent lamp categories include smooth, double-color, grinding, sandblasting, light diffusion, semicircle, etc.

PC tubes chimney as long as used to manufacture LED energy-saving lamps, LED energy-saving lamps due to its privileged energy-saving effect, more and more get the market approbate, such as the ordinary sunlight 40 w light intensity, LED lamp only need 12w can achieve the same intensity, Moreover LED fluorescent lamp of long service life, and does not have mercury pollution.

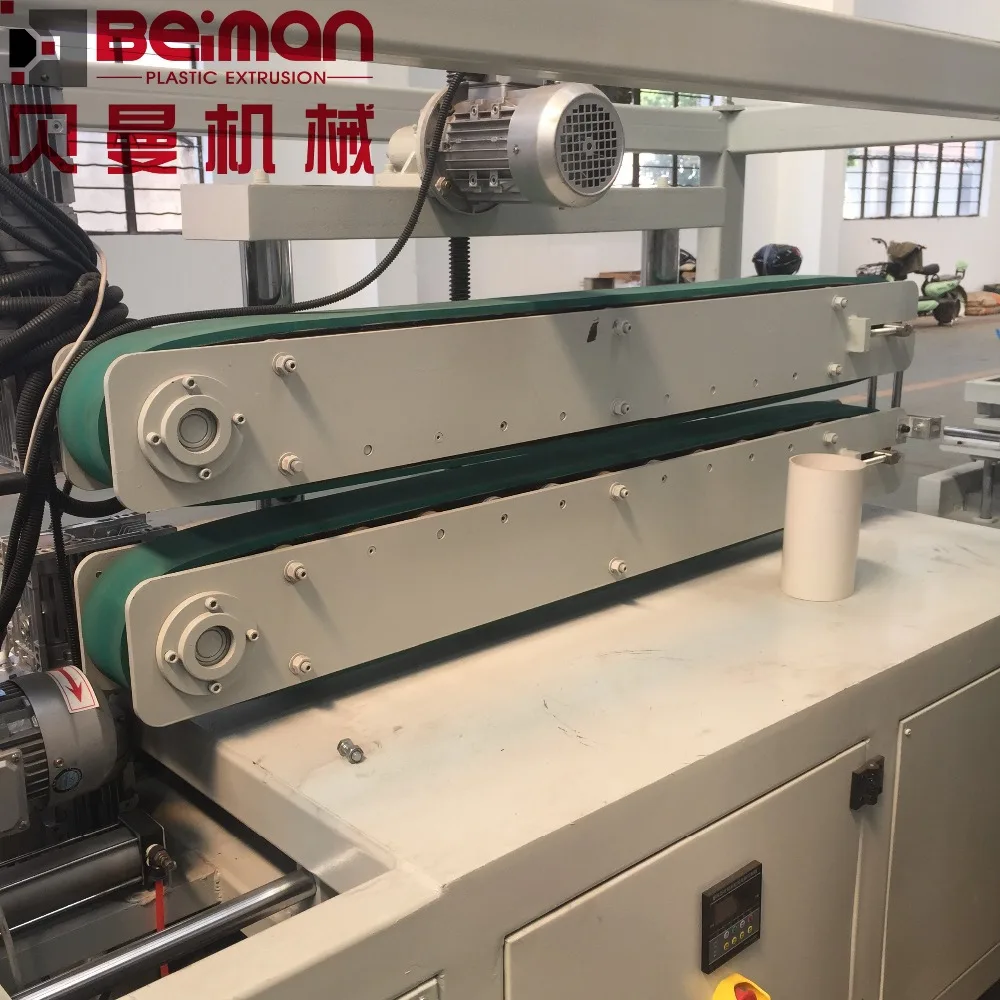

Pc tube extrusion production line is mainly composed of chimney profiles extrusion host, 3d electric calibrating bench, belt gauzing machine, cutting machine, feeder components. Extrusion host adopt efficient extrusion screw, variable-frequency regulating speed technology, on the basis of various specifications of product configuration of different specification host, Calibrating bench adopt stainless steel wet pan, match domestic brands vacuum pump. Drawer adopts Siemens motor, frequency conversion control, manual or automatic electric lift, belt traction, Cutting machine adopts imported sawblade positioning cut off.

NO. | Major parts | Detail information |

1 | Vacuum Loading Machine | Driving motor: 1.15KW |

2 | Drying Hopper | electric heating power: 6KW, blower: 0.25KW |

3 | SJ-50/28 Single Screw Extruder | Driving motor: 15KW, Capacity: 50-60KG/HOUR |

4 | SJ-45/28 CO-Extruder | Driving motor: 11KW |

5 | LED tube Moulds | Pipe size: T5 T8 T10 T12 |

6 | Pipe Vacuum Forming Tank | Tank length: 2000mm; vacuum pump: 2.2KW, 1pc Water pump: 0.37KW, 1pc, stainless steel tank |

7 | Pipe Spray Cooling Tank | Water pump: 3KW |

8 | Pipe Haul off Machine | Haul off motor: 0.75KW, 2pc; inverter control |

9 | Dust Free Pipe Cutting Machine | Cutting motor: 0.75KW, Cutting type: dust free cutting |

10 | Pipe Stacker | Stacker Length: 2meter, automatic control |

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

BEIMAN MACHINERY CO., LTD

BEIMAN MACHINERY CO., LTD special in manufacturer plastic pipe extrusion machine and mixing feeding system Etc., we Have more than 10 years experience in plastic extrusion machine industry filed,and very good at complete extrusion project such as from material to end product. If you are interested in our machine ,please do not hesitated to contact us , we will customized extrusion solution according to your specail requirements.