Product Description

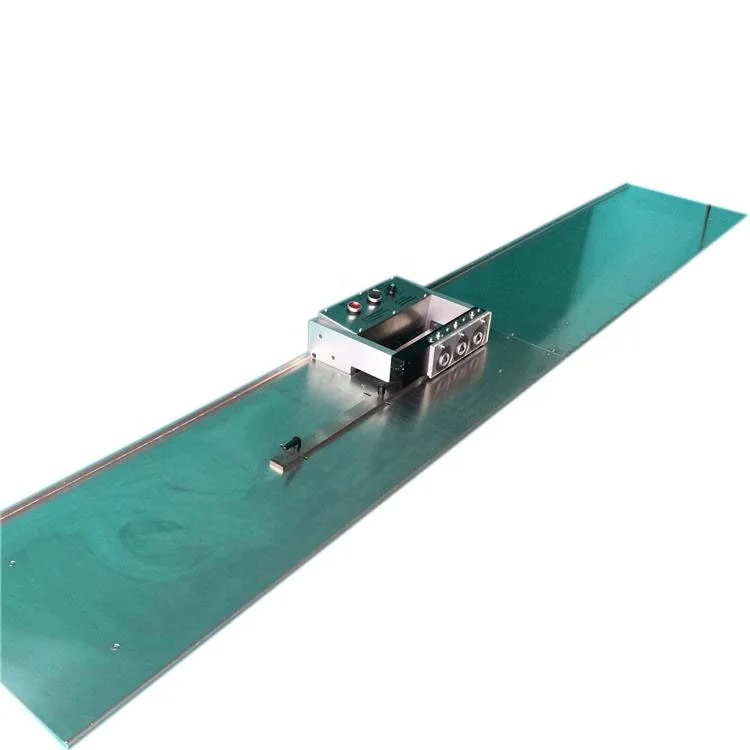

The lPCB cutting machine is the most common dividing equipment in the market at present ,Can be divided into multiple materials with V slot PCB board . Standard voltage design for AC 220V,Concentrated on the realization of a variety of plates,Multiple Specifications,The function of the precision splitter.

Main function |

1. For PCB aluminum substrate, fiberglass board, copper substrate, etc.. Plate bar with V slot . A splitter is equivalent to nine manual manual splines, which improves efficiency and saves labor and labor. 2. Test with 18W panel light. 3. The maximum number of manual hours is 500, and the force innovation machine is at least 3,000. For example, the factory produces 20,000 18w panel lights and works 8 hours a day. Then the 20000 sub-board needs 5 people, 100 yuan per person per day, need at least 500 yuan, and it takes only about 7 hours for one person to operate the innovative light board sub-board equipment. 4. Greatly improving efficiency and reducing costs. |

Use instructions |

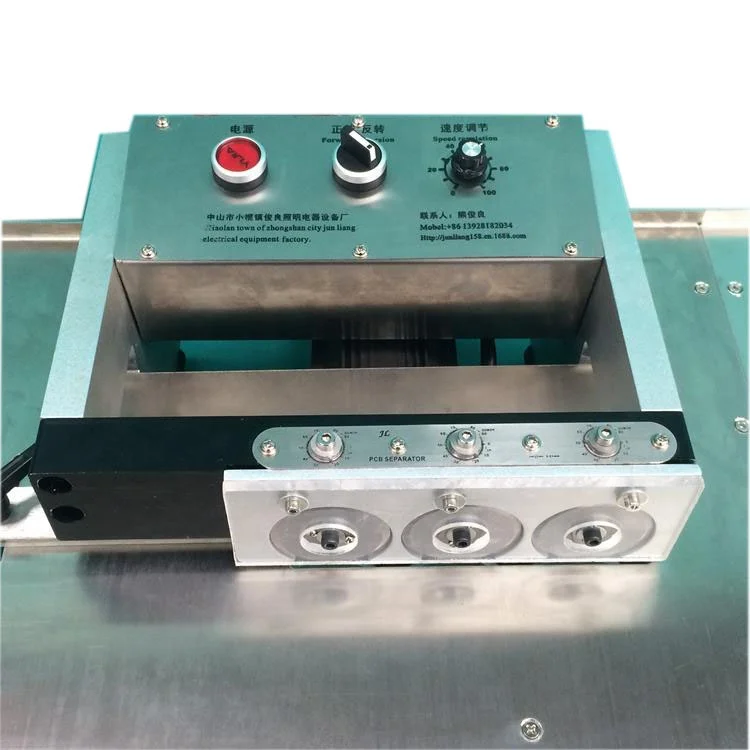

1. Adjust the range according to the width of the lamp : ▶release the accurate distance to push aside; ▶take a piece of plate,hands within the range of manual push board, Until the machine blade just stuck into the panel V slot. ▶push the reference to the edge of the plate, and fix |

2. The state of the blade is that there is a gap between the first blades, Fixed when used for cutting plates,The second blade has no voids and performs 40 % slitting function;The third set of blades were slightly separated . When cutting the plate, the first two groups of blades only rotate the lower blade, and the upper blade does not move or move.Third group blade final splinter,The inertia after the separation of the plate drives the upper and lower blades to turn. |

3. Open the machine, experiment the cutting board. The board passes faster, cuts out the light bar to level, does not twist not twist. If the board is not up to speed, adjust the distance between the blades until the optimal state. With speed control button controller control speed. |

Product Advantages |

1. High performance and security; Easy to operate, save labor. 2. Unique modeling, practical operation, gorgeous appearance, using advanced painting technology. 3. Cutting principles:PCB V-CUT, Three sets of blades, up and down two for a group, squeeze cut lamp plate, do not hurt lamp beads. 4. When cutting, you only need to hang on the PCB to achieve the ideal cutting effect. 5. Reduce the physical length of the cutting and avoid cracking of the solder joint. 6. For all types of V-CUT PCB board. |

Shipping and Packing Scenes

Company Environment

Customes pictures

Part Customers

FAQ

You Ask: |

1:I want to start this business, but I don’t have any experience,how can you help me? A:We have been in the equipment industry for more than ten years and have rich experience in building LED/TV/Mobile Phone/Power Supply/Refrigerator compressor factories.We can provide one-stop support and services from factory construction to raw material procurement to related equipment procurement to factory production. |

2:I want to start this business, but I don’t have enough funds,how can you help me? A:First of all, the equipment with higher automation is not necessarily suitable for you, but the price is definitely expensive.We will provide the machine solution that best fits your current capacity and budget. Manual or semi-automatic machines, coupled with good production management, can also produce good products. |

3:I have been in this business for several years, but the production capacity has been very low,how can you help me? A:How efficient are your employees? Is your machine stable? How do you test and age products? How is the market feedback on your product quality? |

4:My factory has been opened and the equipment has been bought. Can you give me any suggestions for upgrading my company? A:Please send me your current production equipment pictures and on-site production videos.Manual operations can be upgraded toflow belt line operations, manual machines can be upgraded to semi-automatic or fully automatic machines, and single station machines can be upgraded to multi-station machines. |

5:I bought your machine, but I can’t install and operate it,how can you help me? A:All equipments enclosed “Installation and Operation Manual”.You can take your samples to our company for production demonstration, training how to install, operate and maintain the equipment.And we also can provide engineers to your factory for installation and training service. |

6:Although your engineers have completed the installation and training in our company, how can I slove it if the problems of equipment appears again after returning to China? A:First,we can provide online WeChat and video remote instruction,remotely modify or upgrade programs,and ship the spare parts by Air.After this series of operations, the problem has not been resolved, we will send engineers to your company to provide on-site services. |

We Ask: |

1:What’s the products you are producing or plan to producing? 2:What’s your production capacity for 8 hours? 3:What’s the detailed information of your products? 4:How do you plan your factory,that’s also mean what’s the machine you plan to purchase? 5:What are the issues in your factory planning process? 6:When will you plan to start the project? |

Contact Information

Charlie Yang(杨春林) Shenzhen Carst Technology Co.,Ltd Mob:+86 15013801065 Email:charlieyang@carstker.com WeChat/Whatsapp: +86 15013801065 QQ:1090296323 LinkedIn:Charlie Yang Web:www.carstker.com ADD:No 201, Building A, Nandong Third Industrial Zone, Shajing Street, Baoan District, Shenzhen, China |