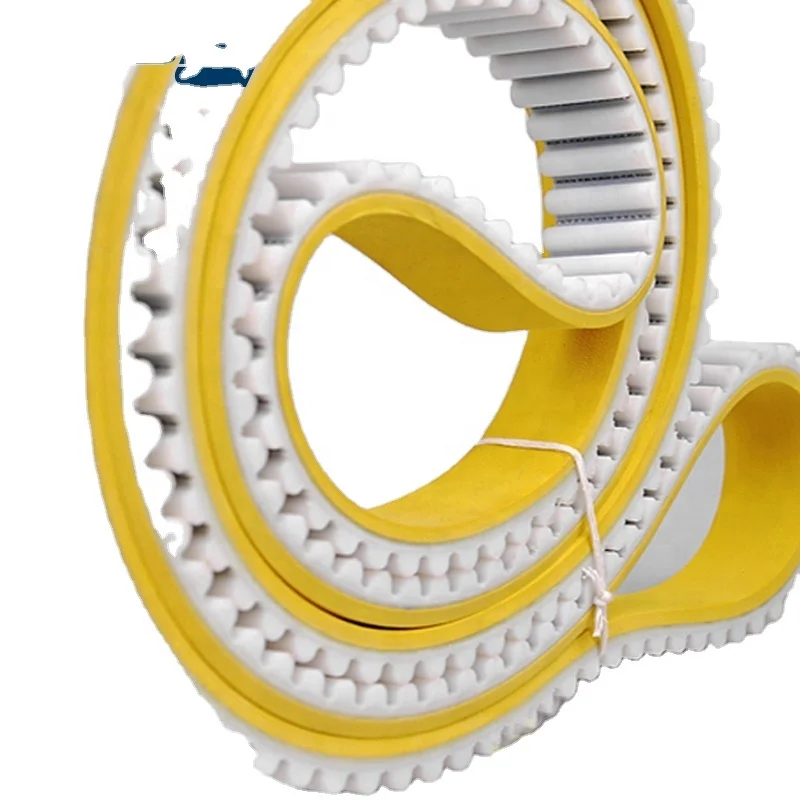

PU material Power driving Red yellow black rubber coated connecting timing belt

CPT can produce open end timing belt, endless timing belt and connecting timing belt with coated rubber, coated cloth and coated stripe in red, yellow, white, green and black. These timing belts are used to transmit power for different kinds of machines. They should be worked together with timing pulleys with profile MXL, L, H, XH, 3M, 5M, 8M, 14M, T and AT.

| Product Name | Rubber coated connecting timing belt |

| Timing Belt Tooth Profile | T, AT, 3M, 5M, 8M, 14M, TK, XL, L, H, DH, XH |

| Timing Belt Width | 10mm ~ 100mm |

| Timing Belt Length | Cut any length |

| Connecting way | Connecting, open end, endless |

| Tooth Side | Single side tooth, double side tooth |

| Coating Material | Rubber, PVC, PU, cloth coated surface |

| Coating Thickness | 3mm ~ 10mm |

| Feature | short processing time, stick firmly, No delamination |

| Other Serivice | OEM / ODM |

Sichuan Dawn Precision Technology Co. Ltd was founded in April 1995. Now we are the professional manufacturer of pulley, bushing, and other mechanical transmission parts.

Casting equipment mainly consists of ZZ416 vertical molding casting line, ZZ418 vertical molding casting line, resin-bonded casting line, Z124 molding casting line, Z146 molding casting line, Z148 molding casting line, vacuum casting line, lost foam casting line, casting model production workshop, car-type heat treating furnace, medium frequency smelting furnace , etc.

Heat treatment & surface treatment equipment mainly contains Multi-purpose furnace heat treatment line, pit and box-type furnace, black oxide surface treatment line, black phosphate surface treatment line, pre-treatment processing line, E-coating production line, plating production line, powder coating production line, sewage treatment station and so on.

Casting and forging test equipment includes Germany DBLF direct-reading spectrometer, Heraeus furnace analysis detector, Heraeus thermoprobe, Video metallographic microscope, tensile strength tester, foundry Sand test equipment, SI/MN/P Analysis meter, CS analysis meter, ultrasonic fault detector, etc.

Machining inspection equipment includes CMM, roughness tester, projector, gear testing center, torque testing machine,durability testing machine, loading test bed, Tensile strength tester, noise tester and so on.

Heat treatment testing equipment includes precision metallographic microscope, Vickers hardness tester, Brine-ll hardness tester, Rockwell hardness tester, portable hardness tester, electron potentiometer, salt spray tester, Magnetic particle flaw detector, thickness tester, etc.

- Finish all production process in one company

- Provide needed testing report

- Over 1500 employees

CPT always join in international and domestic exhibition to offer our customers a wide selection of belt pulleys, timing pulleys, couplings, gears, sprockets, reducers, taper bushings, weld-on-hubs, flanges and other power transmission parts. We show our customers our design, dimension and quality to help a better understanding of our products.

Lisa Young

Whatsapp / wechat: 86 132 8126 8355

Skype: lisayoung765