Single module magnetic linear motor multifunction pick and place machine RT-1

Magnetic linear motor multifunctional pick and place machine.

Mounting components: LED, capacitors, resistors, IC, shaped components, etc.

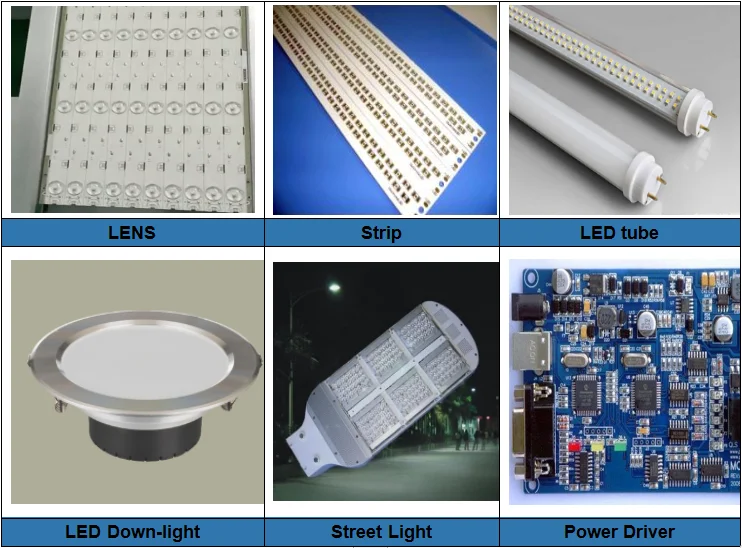

Application: DOB, LED bulb, LED strip, LED tube, lens, Power driver, Electric board, etc.

Support mounting over 22mm high components, very suitable for DOB mounting.

Electronic feeder feeding system.

Vision alignment flight identification, Mark correction.

Auto-optimization after coordinates generations, etc.

Main process of SMT Line for DOB manufacturing

Step one: Print Solder paste on PCB

Step two: Mounting LED chip and capacitor big components on PCB.

Step three: Heating solder paste with PCB to welding together the component with PCB.

Different type of DOB PCBA

The PCBA of Linear bulbs

RT-1 SMT line not only suitable for DOB and bulb, but also suitable for many other products, such as:

|

Number of Heads |

10 |

|

Max Placement Rate |

35000CPH |

|

Max Tape Feeder Capacity |

32 |

|

PCB Length Width |

Max:400*350mm Min:50*50mm |

|

Component Range |

Smallest Size 0402 |

|

Max Height 22mm |

|

|

Length |

1200MM |

|

Width |

1930MM |

|

Height |

1750MM |

|

Total Weight |

2200KG |

Step one: Using Solder printing machine to Print Solder paste on PCB.

Step two: Using pick and place machine to mount LED chip and capacitor big components on PCB.

Step three: Using reflow oven to heat solder paste with PCB to welding together the component with PCB.

============================================

Q1: Are you a manufacturer or trading company?

A1: manufacturer. We have our own industrial park.

Q2: What about the shipping methods?

A2: A variety of transportation methods for you to choose. By sea, air and road.

Q3:What’s your delivery time?

A3:Usually 30 days after deposit, if we have inventory, the time can be brought forward.

Q4:How can you make sure we will receive the machine with high quality?

A4: Our team will inspect each batch of machine before delivery, we have certificates of CE,CCC,SIRA.

Q5:How is your service?

l Our technicians can come to train and install machines, etc.

l We regularly visit customers to understand customer usage and collect customer opinions.

l We regularly provide customers with the latest production technology and equipment information.

Q6:Machine is easy to operate?

A6:Machine is easy to operate,usually 3 to 5 days training of operating is enough.

Add: If you have any other questions, please do not hesitate to contact us, we will serve you wholeheartedly 24 hours!

===================================================================