Dual module pick and place machine

Technical parameter:

HT-E5D is the dual module pick and place machine, there are some important parameter about it.

1. Parameter of PCB:

|

Max PCB l&W: |

500*300 MM |

Min PCB l&w: |

100*100 MM |

|

PCB thickness: |

0.5-3 MM |

||

|

PCB clamping: |

Electric clamping + Adjustable pressure pneumatic |

||

2. Parameter of O.s

|

System: |

Windows 7 |

Software: |

R&D independently |

|

Display: |

Touch screen monitor |

Input: |

Keyboard, mouse |

Application:

The most common use of placement machines is in the production of led lights.

In the assembly of various LED fluorescent lamps or bulbs and spotlights, it is necessary to use a fully automatic visual placement machine. The LED lamps are composed of a large number of small light source patches. This high-precision placement module It is most suitable for installation with a fully automatic visual placement machine, which can continue to operate in large quantities without interruption and without any errors in positioning.

Specifically, HT-E5D can produce led bulb.street lamp, power driver, DOB linear bulb, down-light, lens, panel light,etc.

Features:

|

Dual module pick and place machine |

|

1)Dual system, dual module multifunctional pick and place Machine. To produce two different products at same time. |

|

2) Mounting components: LED/capacitors/resistors/IC/shaped components/etc. |

|

3)Component min size 0402, max height 36mm. |

|

4) Vision alignment flight identification, Mark correction. |

|

5)Non-stop material re-loading function. |

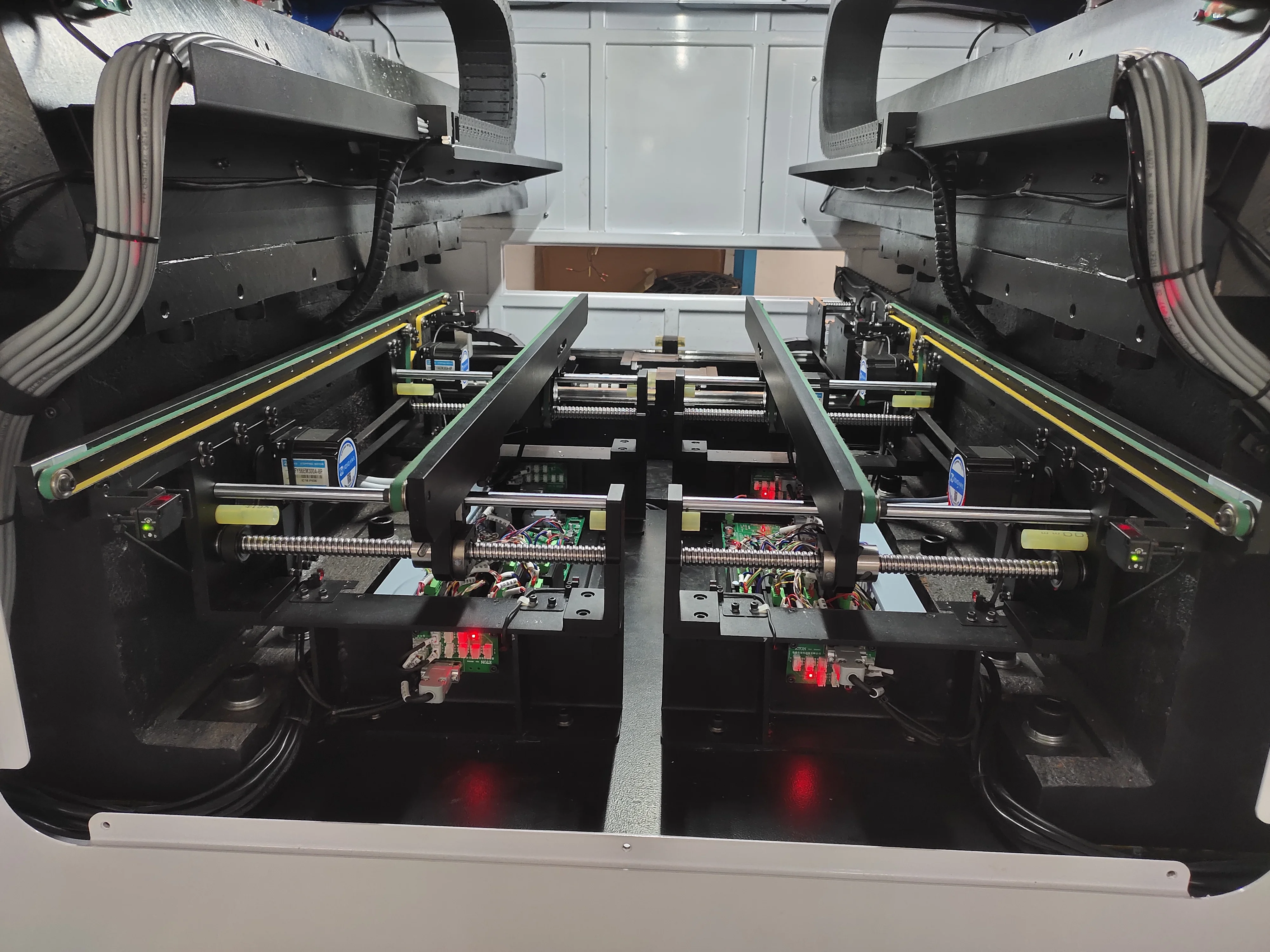

Internal parts structure of the machine:

There are many types of placement machines, but whether it is a fully automatic high-speed placement machine or a manual low-speed placement machine, its overall layout has similarities. The automatic placement machine is a high-precision automation equipment controlled by computer and integrated with the light collector. It mainly consists of rack, PCB transmission and bearing organization, drive system, positioning and alignment system, placement head, feeder, optical The identification system, the sensor and the

Computer control system are composed of the functions of the capture displacement-positioning-placement, and the SMD components are quickly and accurately placed.

1.More advanced linear magnetic.

Suspension motor, in addition to the technical characteristics of each double drive, also has direct drive, less mechanical wear, fast feedback, quiet, easy to maintain and high degree and other characteristics.

2.Flexible PCB clamping

Our PCB clamping is using electric clamping with adjustable pressure pneumatic.

3. Suitable for most of components.

HT-E5D suitable for LED, capacitors, resistor, shaped components, etc.The max size is 17 mm, the min size is 0402.

Logistics and delivery:

|

Transport: |

By sea/Train/Airplane |

|

Packing: |

Wooden box with vacuum package |

|

Lead Time: |

Four weeks after payment |

Company Information:

ETON Automation Equipment Co. LTD located in Shenzhen, China, which is set up in 2011. Focusing on the placement machine industry, there are independent production departments, R&D team, sales team and after-sales service department. There are three offices in China, namely Shenzhen, Zhongshan and Hangzhou. There are also offices in Delhi and Mumbai, India.

Our company is an international development company for global customers. Our placement machines are exported to more than 20 countries and have been well received all over the world. Such as USA,KOREA,GERMANY,EGYPT,TURKEY,VIETNAM,TUNISA

And so on.

After sales service

We provide comprehensive after-sales service, including one year warranty, software and hardware lifetime maintenance, also deal with consumer letters and visits, answer consumer advice. At the same time, in various ways to collect consumer opinions on product quality, and timely improvement according to the situation.

Attention:

There are two points need highly valued:

1.First point requirements, correct installation according to the instructions.

Since the LED placement machine is a highly intelligent production equipment, it should be assembled in the installation instructions when purchasing the equipment, or the salesman's explanation should be assembled, bearing in mind the random assembly. Of course, every LED after-sales manufacturer with good after-sales service will have a door-to-door service. This is a guarantee for the product. Since the professional is debugging the device, the placement machine can be used nor

2.The second point requires, adhere to the cleaning of the working environment

The working environment of the LED placement machine should be kept clean, which is very important for the application of the placement machine. Since the LED placement machine is an LED component, the LED component is attached to the circuit board. If dust is present, it will affect the normal operation of the LED product. And because the entire operation process of the placement machine is intelligent operation, the dirt that may be present is likely to affect the normal operation of the equipment, so the placement machine must adhere to a clean working environment.