reference configuration

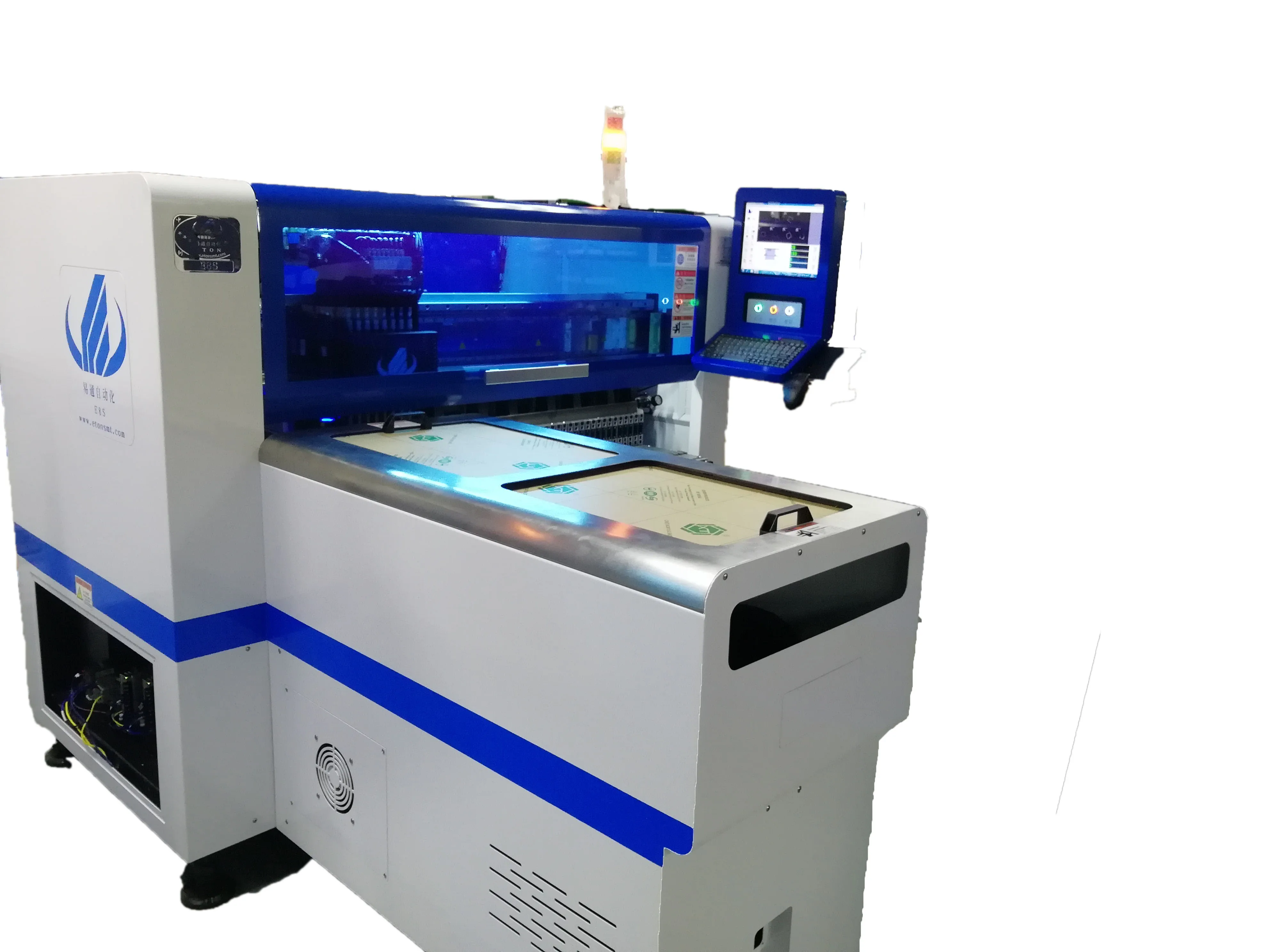

1. Control system: industrial computer + precision motion control card + touch display

2. Software system: ETON independently develops the Chinese and English operating systems

3. Sport motor: panasonic original motor and high-end magnetic linear motor

4. Mount suction nozzle: independently developed several types of suction nozzle

5. Sliding device: precision screw rod + linear guide rail

6. Visual device: MARK point recognition, imported high precision visual camera

7. Feeder: high-speed electric feeder

8. Feeding mode: double motor electronic feeder

|

PCB |

PCB length width |

Max:1200*300mm min:100*100mm |

|

PCB thickness |

0.5~5mm |

|

|

PCB clamping |

Adjustable pressure pneumatic |

|

|

Mounting mode |

ØGroup to picking and separate to placing ØSeparate to picking and separate to placing |

|

|

O.S. |

system |

Windows 7 |

|

software |

R&D independently |

|

|

display |

Touch screen monitor |

|

|

Input device |

Keyboard , mouse |

|

|

Vision system |

No.of camera |

2sets of imported camera Vision for the alignment identification,mark correction |

|

Mounting precision |

0.02mm(repeat precision) |

|

|

Mounting height |

<36mm |

|

|

Mounting speed |

40000CPH |

|

|

Components space |

0.2mm |

|

|

No.of feeders station |

30PCS |

|

|

No.of nozzles |

8PCS |

|

|

Power |

380AC 50HZ |

|

|

Power consumption |

4KW |

|

|

Conveyor transmission |

Max length:1200mm |

|

|

Transmission speed |

>500mm/sec |

|

|

Transmission direction |

Both direction |

|

|

Transmission mode |

Auto online drive |

|

|

Air pressure |

>5.0kg /cm² |

|

|

Electrical control |

Independent research and development by ETON |

|

|

Motion control card module 1set |

Independent research and development by ETON |

|

|

X,Y,X axis drive way |

Servo motor control for X,Y,Z axis |

|

|

Feeding way |

Electric feeder with double motor |

|

Exclusive Patented Technology

Electronic feeder feeding system

Vision alignment flight identification,mark correction

Non-stop material re-loading function

auto-optimization after coordinates generated ,etc.

Company informationShenzhen Eton Automation Equipment co., LTD. is a professional manufacturer of pick and place machine. Our company independently research, development, design and manufacturer a set of high -speed good quality SMT pick and place machine. And we received a number of patents issued by the state certificate and support. Nowadays, we have served many factories and enjoyed good reputation.

Logistics and delivery

Our mode of transportation including water, land and air transportation.You can choose the most suitable way according to your requirements.

|

packing |

|

|

1.Filming packing |

Make the machine sanitary, clean, sealed packaging, dust and humidity; have good shock resistance, impact resistance, and good protection performance with tightness and fixity. |

|

2.vacuum packing |

Advantages of moistureproof, dustproof and so on |

|

3.wooden packing |

It has good cushioning performance, corrosion resistance, high strength and hygroscopicity, moisture-proof and earthquake-resistant functions. |

After-sale Service

Before buying machine

1) Professional sales manager of LED SMT machine, provide professional suggestion and service to you .

2) 24 hours online service and technical support, solve your questions quickly.

3) Sound company organization and working system, guarantee you a fast delivery.

4) Design and provide the whole SMT processing lines for you based on your budget , workshop covering area with best prices.

lwe will send our engineer to your factory to install machine and training freely.

lWe have service office in india,and have indian engineer in delhi and mumbai.Can support quickly.

lStandard warranty is one year,during warranty,any parts need to be repaired and replaced will be free.

1) Do you have oversea after sale service?

We can offer technical support abroad. If you have any technical problem, our engineers will support you promptly.

2) How is the training?

After buying our machines, you can send your engineers to our factory, or we send our engineer to your factory, and then we will train your people to operate these machines.

3) It’s hard to use the machine?

No, not at all. For our previous clients, at most 5 days is enough to learn to operate the machines.

4) Does your machines have quality certificates?

We are high-tech enterprise with CE,SIRA,CCC ,ISO awarded as "Well-know brand" and many technology patents, and have rich experience(more than 8 years) in LED light production line program.

5) What’s the termsof payment? What about the trade term?

T/T is OK. You can choose FOB Shenzhen.