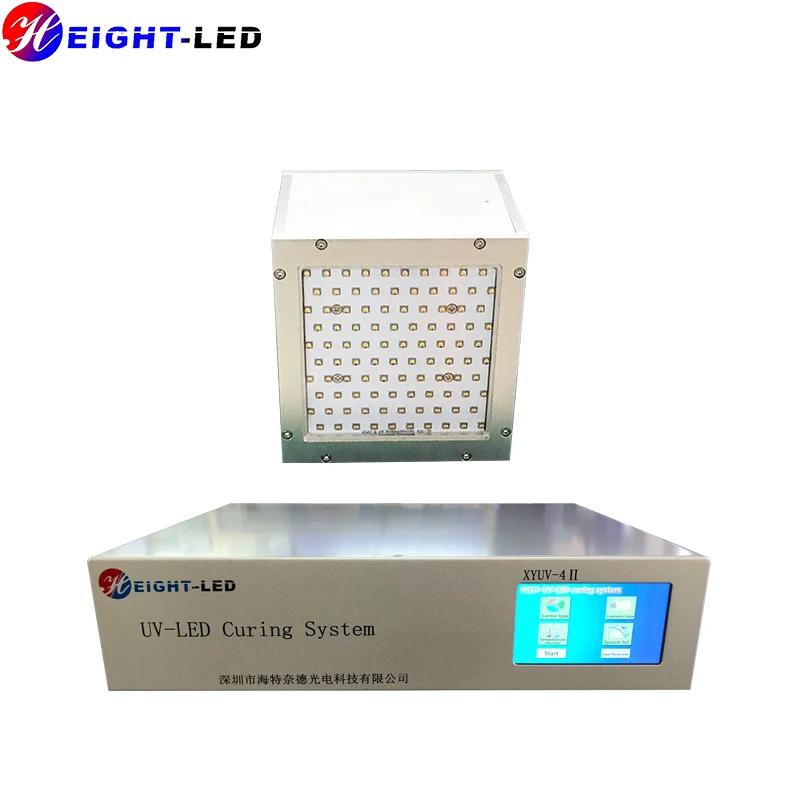

Product Description

Specification

Wavelength(±5nm) | 365nm | 385nm |

Curing area | 100*100mm | 100*100mm |

Power intensity | 1300mW/cm2

| 1800mW/cm2 |

Optical power adjustable range | 0-100% | 0-100% |

Best Curing distance | 10mm | 10mm |

external dimensions | L160*W175*H86mm | L160*W175*H86mm |

Working environment temperature | 25℃ | 25℃ |

Electric power | 300W | 300W |

Cooling Method | Fan cooling | Fan cooling |

Life | ≧20,000 hours | ≧20,000 hours |

Product Application

Company Profile

Shenzhen Height-LED Opto-electronics Technology Co., Ltd located in Shenzhen, Guangdong, China. Starting in 2007, Height-LED engaged in UV-LED curing UV ink, UV adhesive UV paint, UV varnish and other UV sensitive materials. Our team has more than 10

years combined experience in UV curing systems and can meet the requirements of each client.

years combined experience in UV curing systems and can meet the requirements of each client.

Our Advantages

Product Advantages

* Extra-long life: 25000h~30000h

* Energy saving: save 80% electrical energy than Mercury lamp

* UV output adjustment: From 1% to 100%

* Multiple control modes : Constant current, pedal control, intelligent optical and manual modes

* Photoelectric induction, instant on/off, no preheating required

* Low energy consumption, just 20% of the ordinary uv lamp

* No mercury, No Ozone, eco-friendly

* Cold light source, low temperature

* Stable output, high uniformity

* Instant on/ off, no preheat required

* Extra-long life: 25000h~30000h

* Energy saving: save 80% electrical energy than Mercury lamp

* UV output adjustment: From 1% to 100%

* Multiple control modes : Constant current, pedal control, intelligent optical and manual modes

* Photoelectric induction, instant on/off, no preheating required

* Low energy consumption, just 20% of the ordinary uv lamp

* No mercury, No Ozone, eco-friendly

* Cold light source, low temperature

* Stable output, high uniformity

* Instant on/ off, no preheat required

Certifications

FAQ

Q1: Why choosing HTLD UV LED curing system?

A:Our team has over 10 years combined experience in UV curing systems and can meet the requirements of each client.

Q2: Can I use UV LED curing system in our production?

A:HTLD UV curing system can be used for curing UV ink, UV adhesive UV paint, UV varnish and other UV sensitive materials.

Q3: What is UV LED curing system’s major advantages than other UV curing system?

A:Extra-long life, energy saving and environment friendly.

Q4: Which wavelength do I need?

A:It depends on your UV sensitive materials.

Q5: How much the size of emitting window do I need?

A:It depends on your production.

Q6: How much the Peak Irradiance do I need?

A:It depends on your UV sensitive materials and your Production efficiency.

Q7: The common emitting window and Peak Irradiance can not meet my requirments?

A:Do not worry! Any size of emitting window and Peak Irradiance can be customized .

Q8: Where is your company located?

A: 2/F, Building B, Sanhe international science and technology Building, Lai Wu Shan New Village ,Da Lang Road,Long Hua District, ShenZhen.

Contact Us