Product introduction

Product introduction

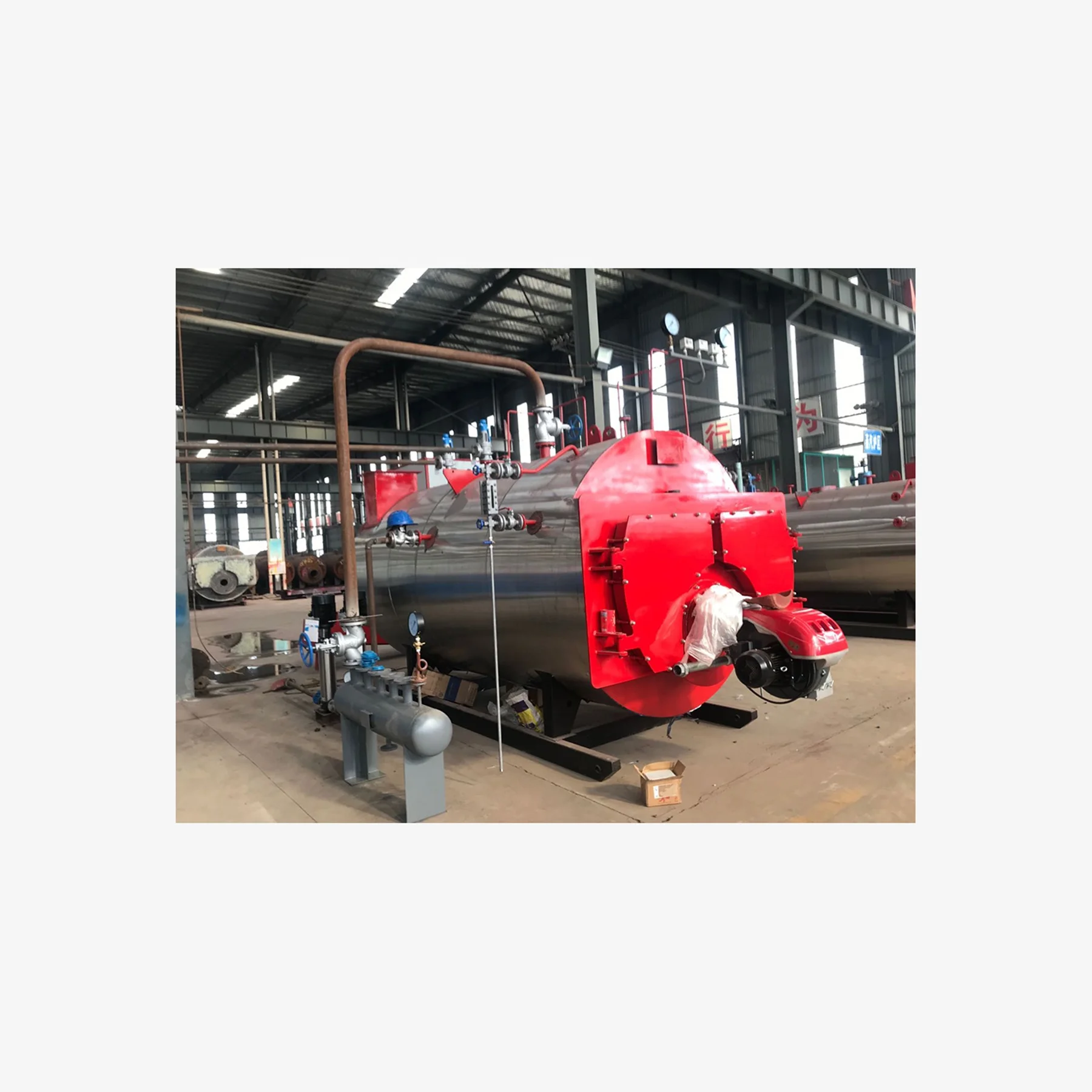

WNS type horizontal full-automatic gas boiler is a horizontal internal combustion three-return fire tube boiler. Using offset furnace liner wet back structure, high temperature flue gas washes the second and third return smoke pipes in turn, and then is discharged into the atmosphere from the back smoke chamber through the chimney. The boiler is equipped with movable front and rear smoke box covers to facilitate boiler maintenance. Industrial burners with good technical performance are equipped with advanced technologies such as automatic proportional adjustment of combustion, automatic adjustment of water supply, program startup and shutdown, full-automatic operation, etc., and have automatic protection functions such as high and low water level alarm, extremely low water level, ultra-high steam pressure, flameout, etc. This type of boiler has the characteristics of compact structure, safety, reliability, simple operation, rapid installation, less pollution, low noise, high efficiency, etc.

Model specifications | Rated evaporation (T/h) | Rated working pressure (Mpa) | Saturated steam temperature (℃) | Nitrogen oxides (Mg/M3) | Design fuel | Transport weight (KG) | Maximum transport size (MM) |

WNS1-1.25-YQ | 1 | 1.0 1.25 1.6 2.5 | 184 194 204 225 | 18-30 | natural gas Light oil heavy oil Wait | 4800 | 3200x1800x2000 |

WNS2-1.25-YQ | 2 | 7200 | 3800x1900x2200 | ||||

WNS3-1.25-YQ | 3 | 10000 | 4100x2000x2400 | ||||

WNS4-1.25-YQ | 4 | 12400 | 4400x2300x2600 | ||||

WNS6-1.25-YQ | 6 | 16000 | 5300x2400x2700 | ||||

WNS8-1.25-YQ | 8 | 21500 | 6800x2600x3000 | ||||

WNS10-1.25-YQ | 10 | 26000 | 6300x2700x3200 | ||||

WNS12-1.25-YQ | 12 | 31000 | 6700x2700x3200 | ||||

WNS15-1.25-YQ | 15 | 40000 | 8700x3700x3500 | ||||

WNS20-1.25-YQ | 20 | 48600 | 8050x3750x3950 |

Contact information

Why Choose Us

here.

1, the company has a full-time after-sales service center and full-time after-sales service personnel:

The after-sales service center is under the management of the sales department, with full-time staff staffed by skilled and rigorous comrades. After receiving the user service information, the province will provide 24-hour and 48-hour services.

2. After the maintenance personnel arrive at the post, the trouble cannot be eliminated overnight. After the trouble is eliminated, the maintenance personnel cannot leave until the normal operation lasts for more than five hours.

Second, strictly implement the after-sales service terms in the contract. The warranty period for sold products is one year, and the "three guarantees" are implemented. For products beyond the warranty period, the service channels will always be unblocked, and the products will be serviced for life without service charge. Guaranteed: users do not have questions, products do not have faults, and services are available on call.

Third, continuously understand the opinions of users and take the feedback information from users as an important source to improve product performance and product quality. Where the product is installed, the feedback of after-sales service information will follow. Establish after-sales service network, get in touch with users frequently, and constantly guide users to maintain and use equipment correctly to prevent failures.

Four, strictly implement the company's after-sales service and management system:

1. After-sales service personnel are enthusiastic in attitude, considerate in service, skilled in technology and excellent in style.

2. The after-sales service personnel will not give users random distribution, arbitrary charges or add any trouble or burden. No fees other than those stipulated are allowed

Packaging and transportation

PACKAGE :The equipment and large auxiliary equipment are bound and fixed in the container

Other small fittings are bound and fixed in strong wooden cases.

Transport :Products can be transported to ports designated by customers by ships and trucks.

DELIVERY TIME:3-25 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Other small fittings are bound and fixed in strong wooden cases.

Transport :Products can be transported to ports designated by customers by ships and trucks.

DELIVERY TIME:3-25 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Company Profile

Henan Yongxing Boiler Group Co., Ltd. is a group company specialized in research and development, manufacturing, sales and installation services of various boilers and various thermal mechanical equipment. The company holds Grade A boiler manufacturing qualification, A1 and A2 pressure vessel manufacturing qualification and mechanical and electrical equipment installation engineering professional contracting qualification, and has passed the international ISO9001 2000 quality management system certification. The company strictly abides by the guarantee mode of ISO9001 international quality management system, carries out quality management and quality inspection control activities, and ensures stable product quality. He was awarded the title of "enterprise that respects contracts and keeps promises" by the Henan Provincial Administration of Industry and Commerce, the title of "national enterprise that abides by the law and integrity" by the Ministry of Agriculture, and the title of "member unit" by the China Association for Quality and Technology Supervision. He has obtained many patented technologies. The company's coal-fired, oil-fired, gas-fired, electric heating, steam boilers, hot water boilers, boiling water boilers, organic heat carrier boilers, hot air stoves, and gas integrated environmental protection boilers and pressure vessels developed around the difficult problem of coal-fired environmental protection strictly comply with national and industry standards. The products have reasonable design, advanced production process and leading technical content among similar products in the country. They are featured by compact structure, low noise, high thermal efficiency, safe and reliable operation, and high degree of automation. All environmental protection indicators meet the requirements of national environmental protection standards in Class I regions and are excellent products recommended by environmental protection departments. The company covers an area of 60000 square meters and has fixed assets of 122.7 million yuan only. It is used for more than 100 sets of major large and medium-sized production equipment, more than 60 sets of advanced equipment for product quality inspection, 37 series of boilers and pressure vessels, 167 specifications and models, with an annual production capacity of more than 1,000 tons of boilers and more than 500 sets of Class I and II pressure vessels. It is one of the few enterprises in the boiler industry.