All cables including voltage collecting cable, internal testing cable and other conneting cables are all flame retardant lines, and are in compliance with the fire retardant requirements specified in the UL VW-1 and GBT 18380.1 standard.

Our CELLCHECK intelligent battery monitor is designed special for single cell monitoring. It combines advanced technology with patented hardware for the most thorough stationary battery health analysis in the industry. The module can be pasted on the monitored battery's case directly or mounted an additional rail.

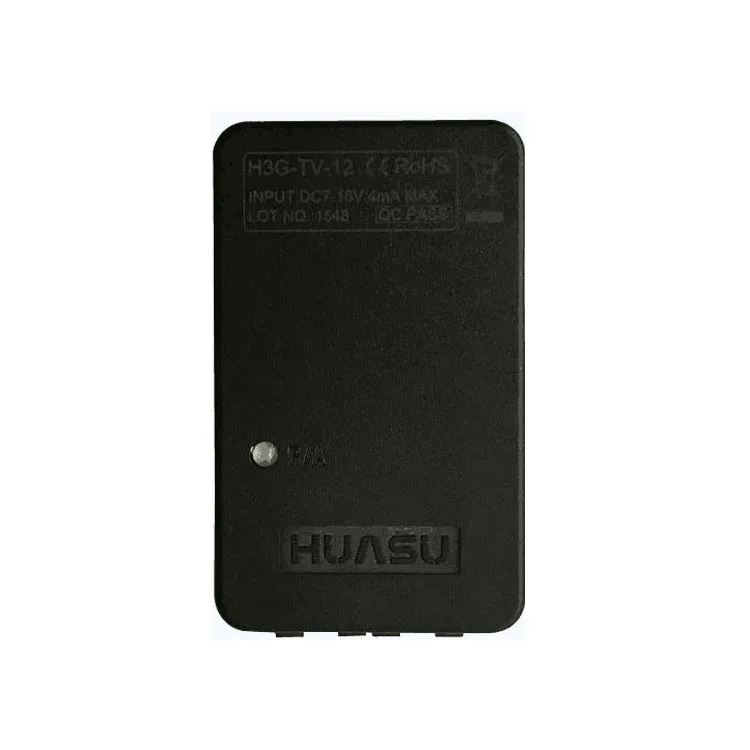

Product Name | H3G-TV12V40S1CT Battery Monitoring System | ||||

Battery Type | 12V Battery Voltage, 4 battery cells per string, 1 string per power system | ||||

Used For | Lead Acid | ||||

Monitoring Parameter | Battery voltage, battery string current, voltage, ambient temperature | ||||

Power Requirements | TV module: powered from the battery,less than 12mA(2V) or 4mA(12V) CM module: 85~264VAC,100V~370VDC,15W TC module:DC8~13V,2W | ||||

Communications Interfaces | TV Module:UART port, meet MODBUS protocolConverter CM module:RS485, Ethernet Port , meet MODBUS/RTU,MODBUS/TCP and SNMP protocol TC module:UART port, meet MODBUS protocol | ||||

Environmental | Storage temperature: -10℃~70℃,5%~90%RH Operating temperature:-5℃~50℃,5%~90%RH | ||||

Application | Data Center/Communication/Transportation etc. | ||||

BMS Components

Overview

• Continuous 24/7 on-line monitoring

• One CELLCHECK monitor one cell, including battery internal resistance, voltage and temperature

• Software is available to collect data from CELLCHECK

• Serial port with Optical isolation, meet MODBUS protocol, easy to be accessed by UPS controller

• Easy to install without specialized training

UL VW-1 Test Method

Packaging & Delivery

Standard Export Carton

Normal Size: 52.3*33.8*19.5

Main Products

• IT Enterprise &Data center

• Telecommunications

• Battery supplied applications

• Utilities

• Fire &Safety system

• UPS System

• Transportation

• Remote monitoring

• Base Station

At HUASU battery monitoring and management is all we do. We keep on researching it intimately, so you don't have to. Our company was established on year 2003, 4 generations (2V &12V concentrated system, cellcheck system, wireless system) BMS has been developed.

We provide BMS products and related services to the world, such as Schneider, Eaton, Emerson, etc.

Profession, specialty, refinement and particularity have been the keys to HUASU's success.

Contact us

Factory Add:2nd&3rd Floor of No.3 Building, No.1418-50 Moganshan Road ,Hangzhou Zhejiang, China

Tel:+86-571-86693075

Fax:+86-571-87968969

Skype: crystal_4637

Mob/WeChat/WhatsApp:18856965962

Website:http://huasu-tech.com//

Our Team

ROHS CE(EMC) UL CE ISO9001

Q1. Why monitoring battery internal Resistance?

A: Generally, we confirm the battery situation through discharging of the battery. With this handling, we can work on the real capacity but it is very time-consuming. After doing reasearchs, we find the internal resistance of the battery will be increased that due to various causes of capacity decline. If we regularly monitor the internal resistance of the battery and compare it with the initial internal resistance, it will be easy to detect the performance change of the battery and also find out the problem battery.

Q2. Why monitoring battery temperature?

A: Battery temperature is like human body temperature, when there is a problem with the battery internal temperature will tend to rise, generally like the battery internal part of short circuit, charging voltage is too high will cause temperature rise. Therefore, the problem of battery pack can be detected as early as possible by monitoring the temperature inside the cell.

Q3. Can your products be discharged remotely?

A: Yes, the control unit can be controlled remotely, and the capacity unit can be controlled by the control unit to discharge the battery. But when discharging, the battery pack needs to be operated manually or other control methods to separate from the power supply system. We have done the whole system including the charger by technology project of remote control, but this method is not promotion, mainly is the present charger stability DC screen is not enough, manufacturers can not guarantee the safety and effectiveness of the remote control function, easily lead to loss of control. At present, the technology of remote discharge products in the market is not mature, as a pilot can, it is not suitable to promote, it is recommended that users do not use this product at present.

Q4. Do your products have the balance function?

A: Yes. We take the method of shallow charge & discharge for the battery to the battery voltage balance section.

Q5. How does the product solve the line interference and the environmental interference ?

A: We have considered various interference conditions during the design , and special EMC is processing on the circuit which can meet the requirements specified in UL and DL / T856 - 2004 , and we have corresponding EMC test reports.

Q6. The equipment can access to the third party system? How to access?

A: Yes. It is very easily access to your third party system. Generally, you only take one or two days to put programs.H3G system comes with a special serial port for the use of third party system, support the MODBUS protocol. The specific access method and communication protocol can be provided by our customer service department.