Description:

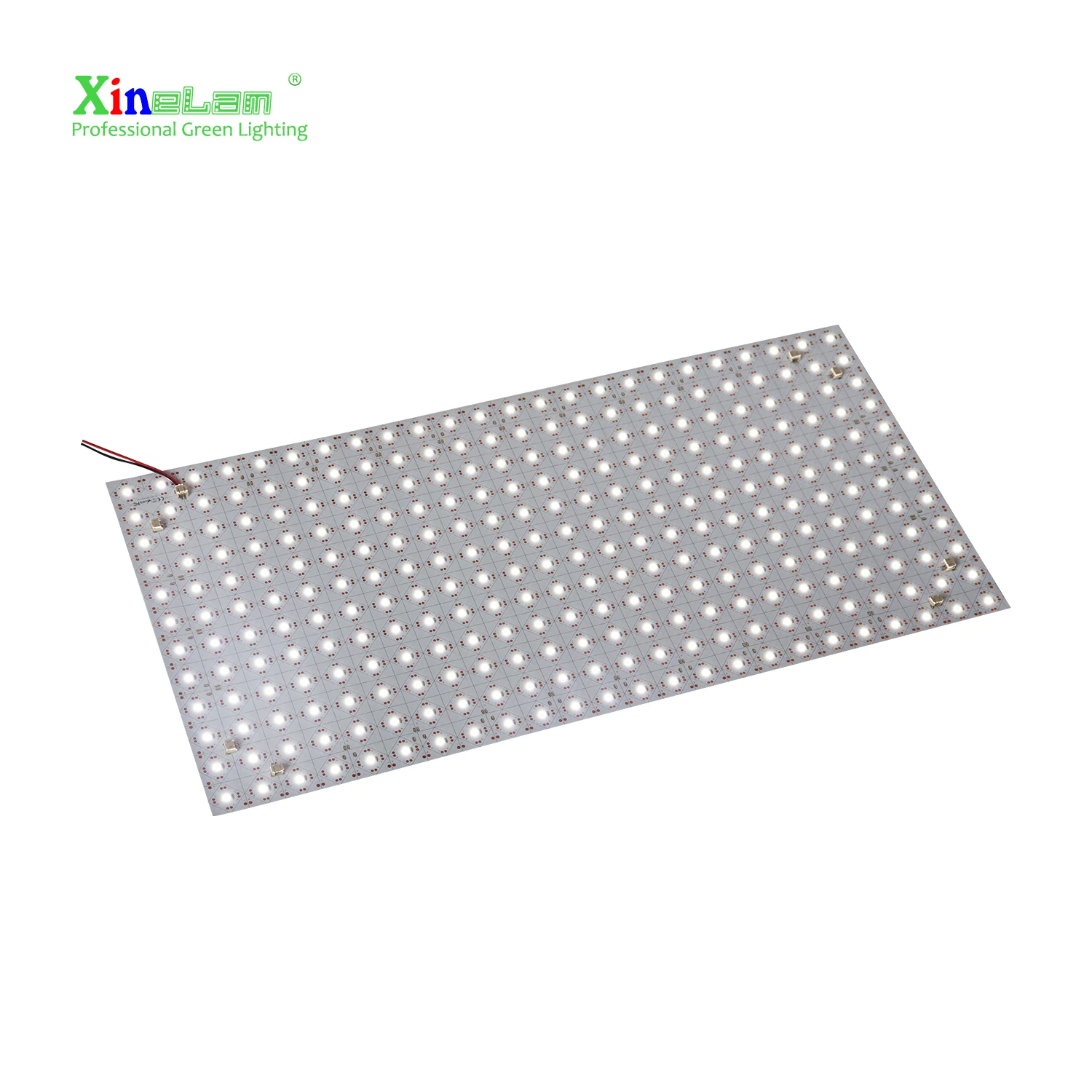

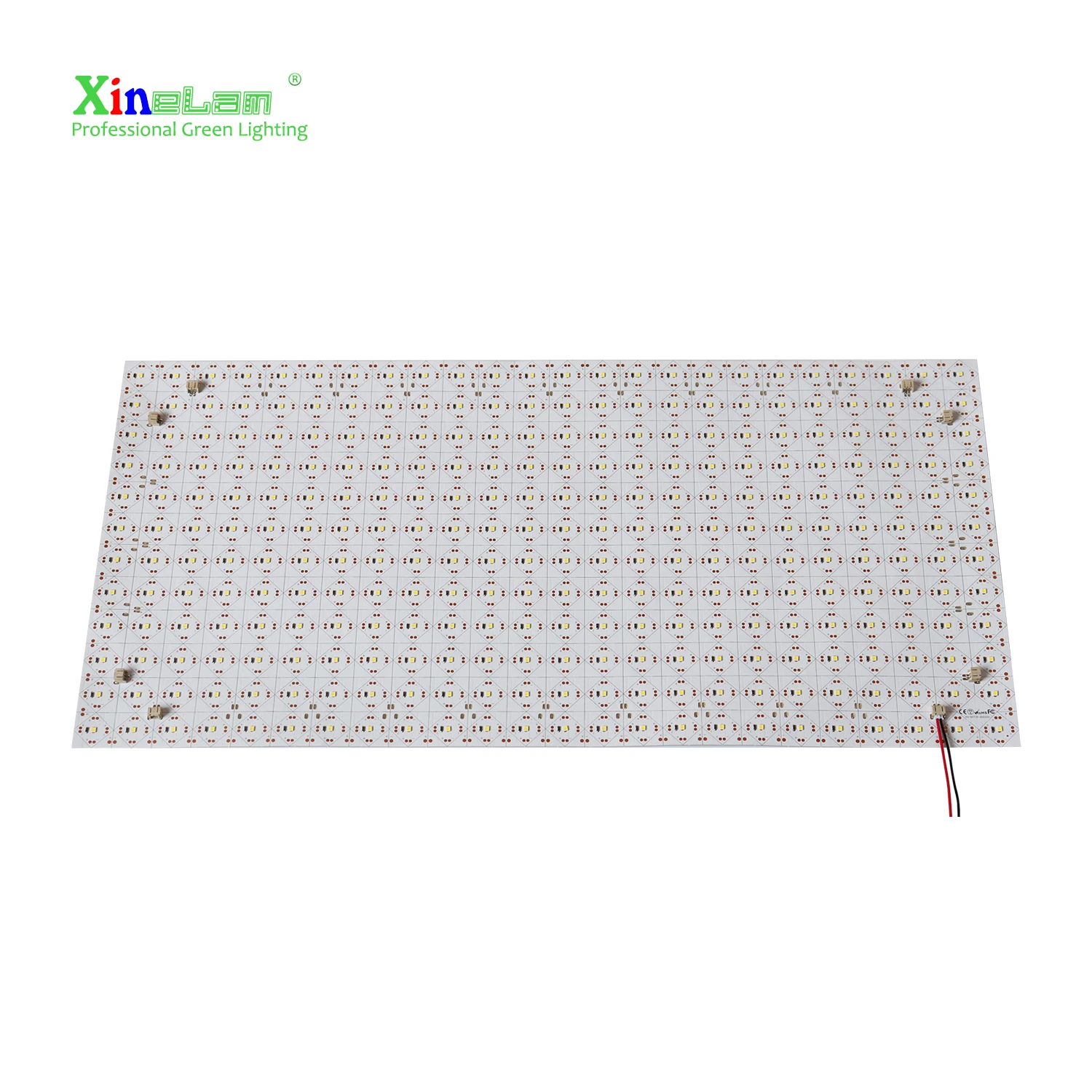

RX-BKT600300 LED Sheet, Patent: ZL201420249938.2, Flexible LED modules; you can cut and splice, making any shape LED module, High efficiency 125Lm / W @ constant voltage drive, Ideal for Light source, Backlighting for advertising, Blister words backlit, LED signs Do your own. energy-saving lighting project.

|

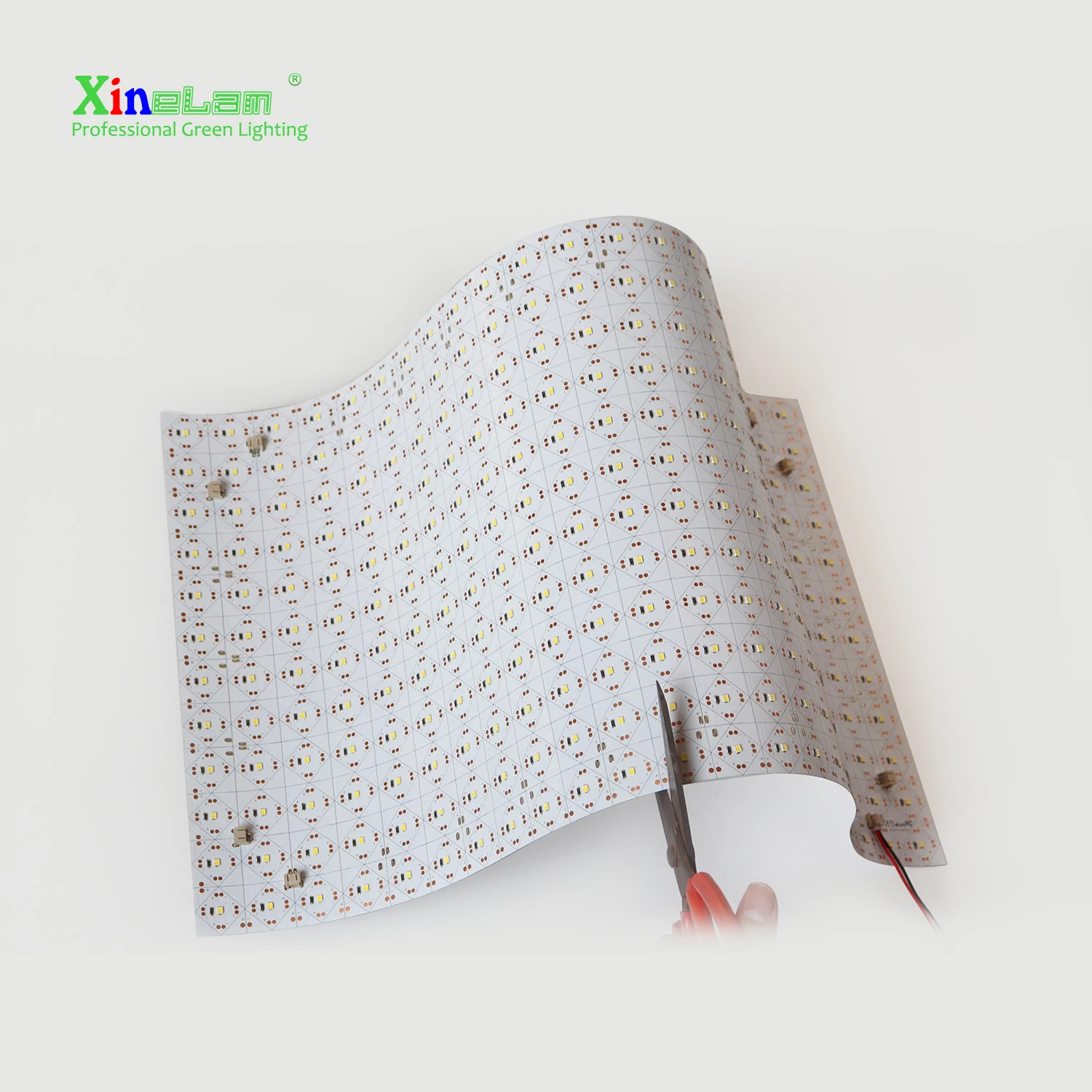

1. One LED cut, It can be cut into any shape!

|

| Model | Dimension Net weight | Power Test & Luminous Flux | Efficacy Typ | Continuous connection QTY | Rated Power | Comment |

| RX-BKT28-600300 | 600x300mm 2ft x 1ft | 61W DC24V 7691Lm | 125Lm/W | 4pcs (240W) Parallel and series | 63W IN DC24V | Tcp 46°C |

| The above table data testing at room temperature is 25 °C, Cooling by free air convection. Lifetime: 40,000 hrs (Note: Tcp < 60 °C) Operation Temperature: -30 °C ~ 70°C At the Tc point Tolerance range for optical and electrical data: ±10 % Test LED color temperature 5800-6500K | ||||||

Customize the power you need, power range 10-100W. Customizing power requires extra cost!

l Dimension

CAUTION: This product is installed by a professional engineering staff.

Safety Information

1. The LED panel itself and all its components may not be mechanically stressed.

2. Assembly must not damage or destroy conducting paths on the circuit board.

3. Installation of LED lamp (with power supplies) needs to be made with regard to all applicable electrical and

Safety Information

1. The LED panel itself and all its components may not be mechanically stressed.

2. Assembly must not damage or destroy conducting paths on the circuit board.

3. Installation of LED lamp (with power supplies) needs to be made with regard to all applicable electrical and

safety standards. Only qualified personnel should be allowed to perform installations.

4. Correct electrical polarity needs to be observed. Wrong polarity may destroy the LED panel.

5. Parallel connection is highly recommended as safe electrical operation mode.

6. Serial connection is not recommended. Unbalanced voltage drop can cause hazardous overload and damage the LED panel.

7. Please ensure that the power supply of adapters power to operate the total load.

8. When mounting on metallic or otherwise conductive surfaces, there needs to be an electrical isolation points between strip and the mounting surface.

9. Pay attention to standard ESD precautions when installing the LED panel.

10. Damaged by corrosion will not be honored as a materials defect claim. It is the user’s responsibility to provide suitable protection against corrosive agents such as moisture and condensation and other harmful elements.

11. Waterproof LED panel , please note waterproof wiring department

12. LED panel can’t be used as support, you need fixed in the frame, fixed to the wall, otherwise, may cause deformation.

4. Correct electrical polarity needs to be observed. Wrong polarity may destroy the LED panel.

5. Parallel connection is highly recommended as safe electrical operation mode.

6. Serial connection is not recommended. Unbalanced voltage drop can cause hazardous overload and damage the LED panel.

7. Please ensure that the power supply of adapters power to operate the total load.

8. When mounting on metallic or otherwise conductive surfaces, there needs to be an electrical isolation points between strip and the mounting surface.

9. Pay attention to standard ESD precautions when installing the LED panel.

10. Damaged by corrosion will not be honored as a materials defect claim. It is the user’s responsibility to provide suitable protection against corrosive agents such as moisture and condensation and other harmful elements.

11. Waterproof LED panel , please note waterproof wiring department

12. LED panel can’t be used as support, you need fixed in the frame, fixed to the wall, otherwise, may cause deformation.