a machine used for pressure casting. Die casting machine under the pressure of molten metal hydraulic injection into the mold to cool the molding, mold can be opened after the solid metal casting.

Product Description

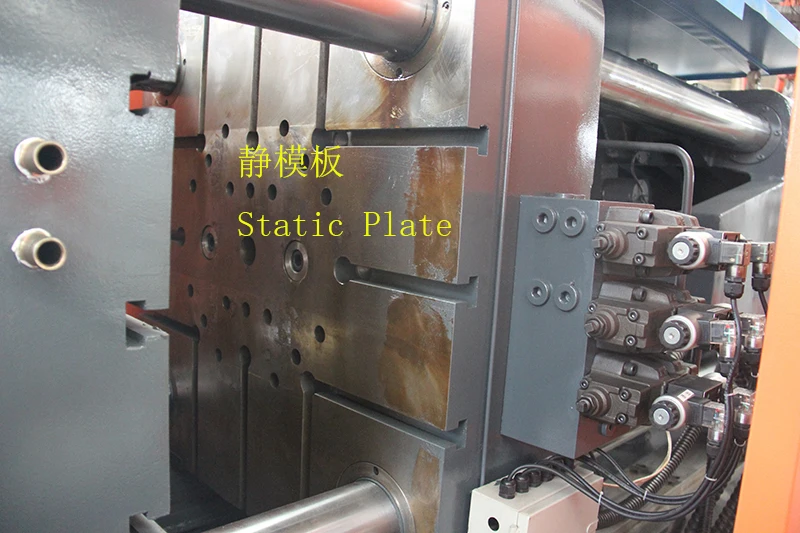

300T Horizontal cold chamber die casting machine series is developed lately by our factory. It is new pattern die casting machine,and which has the character of simple configuration, steady-going performance, and novel appearance and so on. It is an upgrading product j11die casting machine.

This die casting machine belongs to small and medium size, which can cast the small and medium alloy products of aluminum, zinc, copper and some other nonferrous metal. It’s widely used in cars, tractors, electric, meter, aviation, and light industry and the other professions.

Overview of die casting machine workflow

a machine used for pressure casting. Die casting machine under the pressure of molten metal hydraulic injection into the mold to cool the molding, mold can be opened after the solid metal casting.

Die-casting display

there is manufacturing, there is a die casting machine

Size Information

LH SERIES OF STANDARD PARAMETER TABLE (LH-300T)

ITEMS | UNIT | SPECIFICATION |

HYDRAULIC WORKING PRESSURE | MPA | 14 |

CLAMPING FORCE | KN | 3000 |

SPACE BETWEEN TIE BARS | MM | 560*560 |

TIE BAR DIAMETER | MM | 110 |

DIE OPENING STROKE | MM | 420 |

INJECTION FORCE(INTENSIFY) | KN | 315 |

PLUNGER LAUNCH DISTANCE | MM | 140 |

INJECTION POSITION | MM | 0-160 |

PLUNGER DIAMETER | MM | 50-70 |

INJECTION STROKE | MM | 420 |

CASTING PRESSURE (INTENSIFY) | MPA | 143/99/73 |

CASTING FIANGE PROTRUSION | MM | 12 |

CASTING FIANGE DIAMETER | MM | 110 |

MAX CASTING AREA UNDER 40MPA | CM2 | 700 |

LNJECTION WEIGHT(AL) | KG | 3.5 |

DIE HEIGHT(MIN--MAX) | MM | 250-650 |

EJECTOR FORCE | KN | 150 |

EJECTOR STROKE | MM | 120 |

MOTOR CAPACITY | KW | 15 |

MACHINE DIMENSIONS (L*W*H) | M | 6.4*1.7*2.8 |

WEIGHT | T | 12500 |

OIL TANK CAPACITY | L | 750 |

Related Products

Packing&Shipping

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

After Sales Service

Longhua engineers in the customer factory

After the machines arrive in your factory, we will have professional engineers to install and debug the machines, and train your

workers hand in hand until they are skilled in operating the machines and producing qualified products

workers hand in hand until they are skilled in operating the machines and producing qualified products

Company Introduction

Bengbu Longhua , founded in 1982, is a professional high-tech enterprise engaged in the design, manufacture and sale of cold chamber die casting machines, die casting peripheral equipments, oil field equipments and new energy equipments (natural gas, nitrogen, wellhead, casing, raw materials, liquefied petroleum gas, special gas, compressor).

On November 7, 2017, Longhua won the national high-tech enterprise certificate!

On June 26, 2019, Longhua was successfully listed in the National Science and Technology Innovation Special Edition!

Longua intelligent die-casting machines are applicable to manufacture of automobile and motorcycle parts (engine cylinder block, cylinder head, crankcase, hinged door covers, oil pan, gearbox housing, gearbox end cap, dashboard, etc.), electric escalator handrail/steps, industrial/road/railway/air/agricultural machinery, spotlight shells, building material parts, furniture, aluminum arts, copper arts, magnesium alloy products, non-ferrous metal processed products and other die casting products.

Longhua’s quality goal is that "Today’s quality means tomorrow's market".

Why Choose Us

Cooperative r&d unit

Longhua intelligent die casting machine is jointly developed with hefei institute of material science, Chinese academy of

sciences, with automatic system upgrade, one-click operation, zero fault, making die casting more efficient, more precise, more

intelligent and more durable

sciences, with automatic system upgrade, one-click operation, zero fault, making die casting more efficient, more precise, more

intelligent and more durable