The working principle of horizontal cold chamber die casting machine is driven by hydraulic pressure, and the working steps are as follows:

Mold closing - pouring liquid metal - injection - cooling timing - mold opening (punch tracking push out) - casting ejection - ejection reset (end of cycle)

Product Description

LZ series die casting machine is mainly used in the die casting of non-ferrous metals and black metals (parts). Our machines have the following technical features

1 | High duty spheroidal graphite cast iron & slanting structure applied in the die closing mechanism, which assures the long-term accuracy, and decreases the impact while die locking & unlocking, therefore, prolongs the machine’s life. |

2 | Proportional control system applied in the hydraulic system, easy to set up the parameters, and makes the system run quickly, and reliably. The injection system uses an independent accumulator. A fast-response throttle applied in injection and pressurization to increase acceleration greatly and decrease the switching speed between high-speed and boosting, which embodies the excellent injection performance of modern high-quality die casting machines |

3 | In the electric system, PLC components from Mistsubishi & Omron Japan, and electric components from Schneider, France are used. A technician could set up all the parameters by just touching the touch screen. |

4 | Self-check tie-ins are fixed in the lubrication system. A technician could check any oil pipe obstructs by macrography. Under-Voltage Protection could protect the elbows from serious wearing, even breaking because of lack of lubrication oil, and prolongs the machine’s life. |

Direction for use

使用说明

Description of application effect

使用效果描述

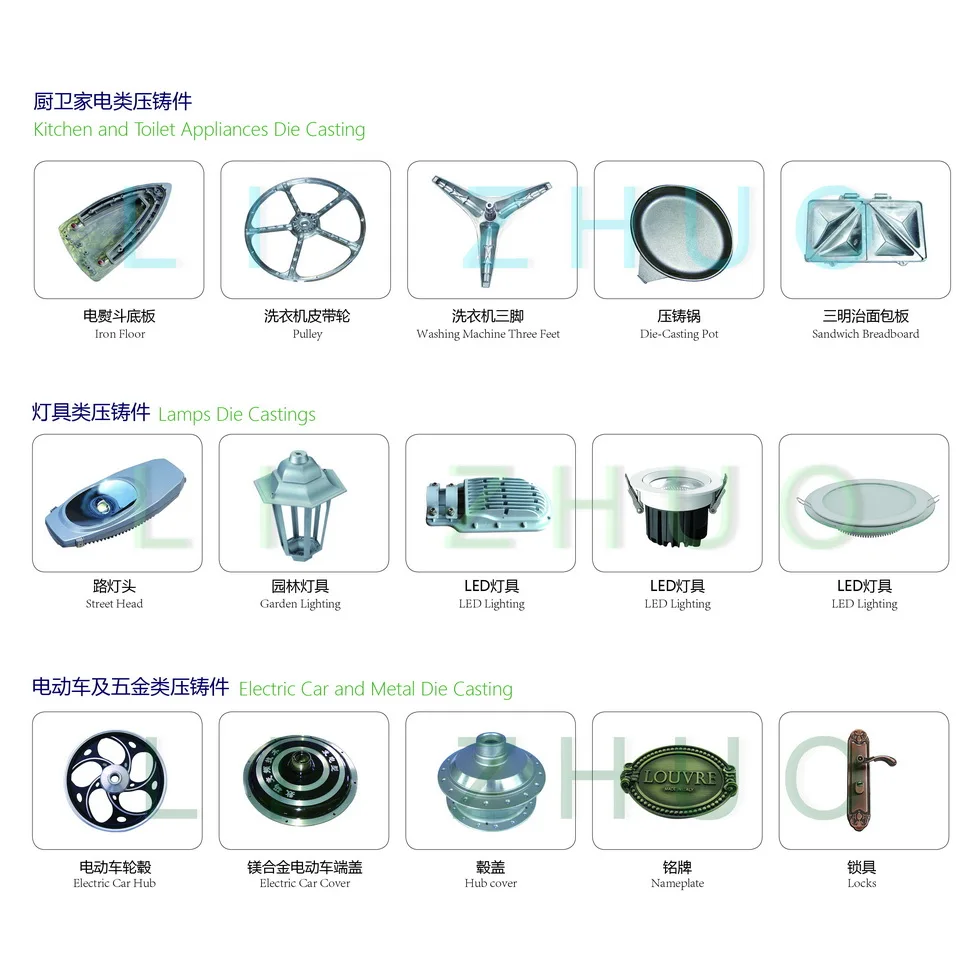

Lz150-2000 series die casting machine has been widely used in automobile and motorcycle parts, electric tools, it, aerospace,

communication, hardware, bathroom, home appliances, lighting, electric equipment, transportation, toys, craft gifts and other

fields.

communication, hardware, bathroom, home appliances, lighting, electric equipment, transportation, toys, craft gifts and other

fields.

Detailed Images

Die casting parts produced by LZ series die casting machine: auto parts, washing machine parts

Size Information

Die casting machine gauge parameter table

Model | LZ160 | LZ180 | LZ220 | LZ268 | LZ300 | LZ350 | |||

Die Locking Force | 1600KN | 1800KN | 2200KN | 2680KN | 3000KN | 3500KN | |||

Model | LZ400 | LZ550 | LZ700 | LZ850 | LZ1100 | LZ1300 | |||

Die Locking Force | 4000KN | 5500KN | 7000KN | 8500KN | 11000KN | 13000KN | |||

Model | LZ1600 | LZ2000 | LZ2600 | LZ3000 | |||||

Die Locking Force | 16000KN | 20000KN | 26000KN | 30000KN |

Related Products

Packing&Shipping

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Company Introduction

Lizhuo (Changzhou) Die Casting Machinery Manufacturing Co., Ltd., is located in Qishuyan Provincial Economic Development Zone,covering an area of 12,000m2. With an assembly workshop over 1,500m2, Lizhuo’s annual output of die casting machines reaches 350units.

Our Services & Strength

Depending on key suppliers, including Qishuyan Locomotive & Vehicle Works, a national large-scale enterprise and a subsidiary governed by the Ministry of Railways, and Baoling Machinery Co., a former national grade-two enterprise and now a Sino-Japan joint venture, the quality of components is highly assured, therefor, the quality of final products are also satisfyingly stable and reliable. In addition, in order to supply better product and service, Lizhuo established an strategic alliance with Fasten Group, Jiangyin, a public company and the largest steel cable manufacturer, which has a postdoctoral working station in cooperation with Harbin Industrial University. Tailun Magnesium alloy Technologies Co., a subsidiary of Fasten, as a strategic partner of Lizhuo, specializes in Magnesium alloy furnaces and full Magnesium alloy die casting technologies. Still, Lizhuo has well-trained and experienced service staffs to offer full and considerate service.

FAQ

Automatic production of die casting machine can improve production efficiency, stabilize quality and save cost