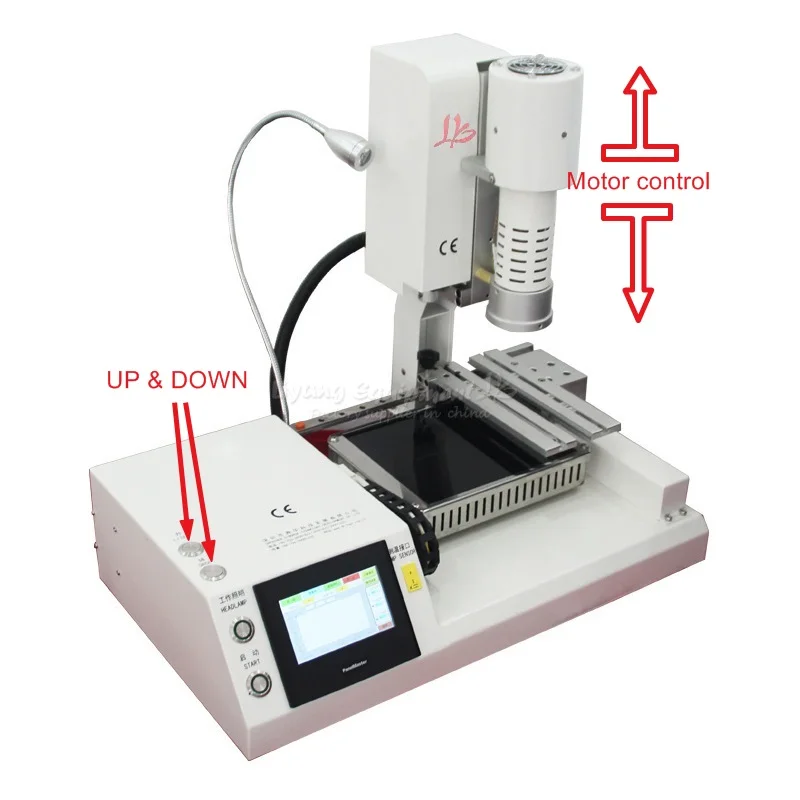

Electrical motor control up down 2 zones Mobile phone motherboard repair station bga rework station LY-5250 total power 2300W

Specification

|

Features:

1.LY-5250 Is special for mobile repairing, such as Samsung, iPhone, Huawei, HTC.... Mini type, lower shipping cost.

2.Top hot air heating, bottom German diode heating zone with glass guard. Top head can move up / down automatic with button. Machine movement with slides, stable and durable.

3.Embedded industrial PC, HD touch screen conversational interface, human-machine interface operation, multi-functional integrated control, human structure design, optional numbers storage, apply temperature curve freely. With multi-functions: “keep same temperature”, “instant curve analysis” and “voice warning before heating finish”. Real-time actual temperature and temperature curve setting can also be used to analyze and correct the curve if necessary.

4.high precise k-type thermocouple closed-loop control, with temperature module and intelligent control unit to enable precise temperature deviation on ±2℃. Meanwhile, external temperature measurement connector enables temperature diction and accurate analysis of real time temperature curve.

5.V-groove PCB works for rapid, convenient and accurate positioning, which can suitable for all kinds of PCB board positioning.

6.Movable universal fixture prevent pcb from damaged on fringe component, suitable for all kinds of pcb repairing.

7.With different size of magnet nozzles, easy replace and install, rotate freely 360°, any size can be custom if need. Titanium alloy material, never deformation, never rusty

8.Two heating zones can independently heat and they are multiple temperature control, which can ensure best integration of different temperature areas. Heating temperature, time, slope and cooling can all be set in touch screen conversational interface. Meanwhile PID calculation to control heating process more accurate and more stable.

9.6-8 segments temperature can be set for top heating and lower heating(up to 16 segments). 50,000 groups of temperature curves can be stored, which can number, modification and apply at any time according to different BGA. Curve analysis, setting and adjustment are also available on touch screen.

10.With Voice warning 5-10 seconds before heating finish: remind operator to pick up bga chip on time. After heating, cooling fan will work automatic, when temperature cool down to room temperature ( <45℃ ), cooling system will stop automatic to prevent the heater from aging.

11.CE certification approval. Double protection: Overheating guard + emergency stop function.

Why our machine more accurate?

Our machine use PID control, the data acquisition frequency of our machine is 10ms(which means every 10ms the PID will grab the data to correcting the temperature, but for most of BGA rework station from other companies, their PID grab frequency is 30ms, this is a big difference between 10ms and 30ms, that's why our machine is more accurate. |

1.We provide you the friendly English User manual or operating videos for free.

2.24 hours technical support by email or calling.

3.Warranty: 1 year free, 2-3 years cost price and free technical support always.

4.Free training to make sure you master the operating of our products.

5. OEM/ODM accept . But the MOQ of OEM/ODM is 100 sets.

an style='color:red'>25-30 workdays shipping from China to Russian customers. No need to pay for customs duties and VAT.

D. We can arrange shipment by sea. Minium CBM requirement : 1 CBM

LyBGA factory is located in Shenzhen, China.

Our factory owns 2 brands , Ly and Bauer.

We has 10 years experiences in manufacturing and exporting BGA rework stations.

Our BGA rework stations , such Ly IR6000, Ly IR6500, Ly IR9000,Ly IR-PRO-SC, Ly IR8000, Ly HR560, Ly HR560C, Ly HR500, Ly SV550C, Bauer IR-PRO-SCC ,Bauer OMEGA XD …

CNC machines like cnc 3020/4030/6040/9060 …series products ,Mobile LCD separating stationslike 946D /947B /950V/948V/948B…are hot sale in the world, especially in these countries from North and South American,European and Asian.

1) This is the first time I use this kind of machine, is it easy to operate?

There is english manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.