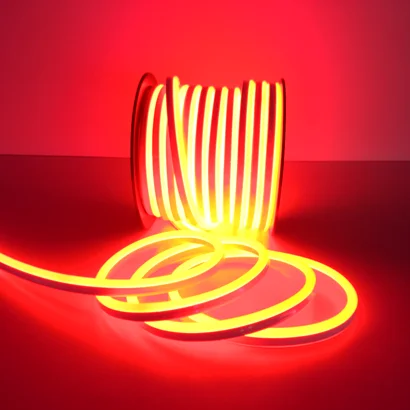

diffuse flexible led strip 12v 24v waterproof led neon flex dc 110V 120V 220V 230V unique structure high quality

LED NEON FLEX - HIGHLIGHTS :

1). 2 X Pure copper wire (0.75 sq . m . measure) as conducting wire, reducing line loss and volt. drop , more stable & safer.

2). Optically modified PVC extrusion : UV stable ; and PVC with heat/cool stabilizer, extremely high /low temp. resistant .

3). Complete kit including adapters, connectors & mounting clips enables easy installation.

4). Flexible, bendable, unbreakable & cuttable (cut at cutting marks).

5). SMD 2835 LED - 0.2W/LED (60mA) - Super Bright

6). No cold weather start problems or color shift.

7). Vivid NEON lighting effect, uniform light, no dots.

8). Waterproof IP65 , ok for indoor / outdoor use.

9). Eco-friendly, energy-effcient, durable, long-life.

LED NEON FLEX : DOMED SHAPE & FLAT SHAPE

1). Domed-shape _ size : 13.5x27mm

More details >>>

|

Model |

OL-NF-240V |

OL-NF-120V |

OL-NF-24V |

OL-NF-12V |

|

Volt. |

240V AC |

120V AC |

24V DC |

12V DC |

|

Cutting intervals |

0.858 m |

0.429 m |

0.143 m |

0.0715 m |

|

Light source |

2835 SMD LED ( 0.2W / LED ) |

|||

|

LED QTY |

84 LED / M |

|||

|

Power |

9 W/M |

|||

|

Dimension |

13.5mm x 27 mm |

|||

|

Beam angle |

270 ° |

|||

|

Colors |

red , green, ice blue, blue, golden yellow, yellow, warm white, natural white, cool white, pink |

|||

|

PVC Jacket |

Milky white jacketed / Colored jacketed |

|||

|

Conducting Wire |

Pure copper @ 0.75 square meters measure |

|||

|

PVC Material |

UV-resistant materials, ultraviolet-proof |

|||

|

PVC stabilizer |

heat / cool stabilizer ; high / low-temp. resistance |

|||

|

Mini Bend Radius |

R 40mm ( sideways bending) |

|||

|

Operating Temp. |

0°~ +45°C |

|||

|

Ambient Temp. |

- 20°~ +45°C |

|||

|

IP grade |

Waterproof IP65 |

|||

|

LED lifespan |

50,000 hours + |

|||

|

Warranty |

2 years |

|||

|

Package |

50m/ roll /carton ; carton size: 36*36*30cm ; G.W. : 23.5KGS |

|||

2). Flat shape _ mini size : 11.5x18 mm

More details >>>

|

Model |

OL-M-NF-240V |

OL-M-NF-120V |

OL-M-NF-24V |

OL-M-NF-12V |

|

Volt. |

240V AC |

120V AC |

24V DC |

12V DC |

|

Cutting intervals |

0.858 m |

0.429 m |

0.143 m |

0.0715 m |

|

Light source |

2835 SMD LED ( 0.2W / LED ) |

|||

|

LED QTY |

84 LED / M |

|||

|

Power |

9 W/M |

|||

|

Dimension |

11.5x18 mm |

|||

|

Beam angle |

180 ° |

|||

|

Colors |

red , green, ice blue, blue, golden yellow, yellow, warm white, natural white, cool white, pink |

|||

|

PVC Jacket |

Milky white jacketed / Colored jacketed |

|||

|

Conducting Wire |

Pure copper @ 0.75 square meter measure |

|||

|

PVC Material |

UV-resistant materials, ultraviolet-proof |

|||

|

PVC stabilizer |

heat / cool stabilizer ; high / low-temp. resistance |

|||

|

Mini Bend Radius |

R 40mm ( sideways bending) |

|||

|

Operating Temp. |

0°~ +45°C |

|||

|

Ambient Temp. |

- 20°~ +45°C |

|||

|

IP grade |

Waterproof IP65 |

|||

|

LED lifespan |

50,000 hours + |

|||

|

Warranty |

2 years |

|||

|

Package |

50m/ roll /carton ; carton size: 36*36*17.5cm ; G.W. : 17KGS |

|||

LED NEON FLEX _ 9 COLORS :

LED NEON FLEX _ ACCESSORIES :

LED NEON FLEX _ 50m / roll / carton :

LED NEON FLEX _ INSTRUCTION

* Use a heat gun to shrink the tubing, heat it evenly, until it 's snug to led neon flex and the edges are slightly beading from glue!

Loading Length :

Installation Precautions :

1. Do not puncture, cut, shorten, or splice LED Neon Flex outside of the designated cutting marks.

2. Do not roll out LED Neon Flex on rough surfaces and over sharp corners. This will scratch the PVC optic.

3. Do not use LED Neon Flex if outer jacket is damaged, loose connections, or if the wire is visible without insulation. Inspect LED Neon Flex periodically for damage.

4. Do not secure LED Neon Flex with staples, nails, or like means that might damage the insulation PVC material.

5. Do not install LED Neon Flex on/in places where it is subject to continuous flexing.

6. Do not operate/run LED Neon Flex in temperatures exceeding +45°C.

7. Do not operate AC240V+ / AC120V+ LED Neon Flex on circuits that do not have proper surge suppression or protection. High Voltage spikes will damage the LEDs.

8. Do not operate LED Neon Flex over the specified voltage or LED life degradation will be greatly increased.

9. Do not leave any part of the LED Neon Flex unsecured. Movement over time from weather can cause damage from continuous movement.

10. Do not cut LED neon flex when it's powered.

11. Do not over extend the mini Bend Radius Lateral of 40mm.

LED NEON FLEX _ APPLICATIONS :

- Path & contour marking _ Elegant interior decoration _ Backlighting for larger size ad-signs

- Landscape outlines _ Signal lighting _ Swimming pool _ Car & motorcycle decorative lighting

- Architectural decorative lighting _ Archway Lighting _ Canopy Lighting _ Bridge edge lighting

- Amusement park lighting _ theater lighting _ Emergency hallway lighting _ Building outlines

- Auditorium walkway _ Stairway accent lighting _ Emergency Exit path lighting _ Cove lighting

FAQ

Q1: Are you a factory?

A:Yes,we are a professional factory focus on LED Neon Flex and LED Neon sign Since 2010

Q2:What is your MOQ?

A:We don't have MOQ requirement,sample order is welcomed

Q3:What certificate do you have?

A:We have UL,CE,ROHS for LED Neon Flex,UL,CE,ROHS,SAA for LED Driver

Q4:What is your lead time for sample order?

3-7 working days

Q5:What is your payment term?

We accept T/T,Western Union,Paypal, etc

Q6:What is your lead time for bulk order?

7-25 working days for different order quantity

Q7: Do you provide OEM or ODM services?

A: Yes, we have more than 10years rich experiences in this production industry, we often cooperate with some famous foreign companies.

Q8:How to deliver the cargo?

<100kgs,Via DHL,FedEx,TNT,UPS for trial orders by Door to door service

>100kgs ship by air for smaller order

>1CBM ship by sea for large order

diffuse flexible led strip 12v 24v waterproof led neon flex dc 110V 120V 220V 230V unique structure high quality