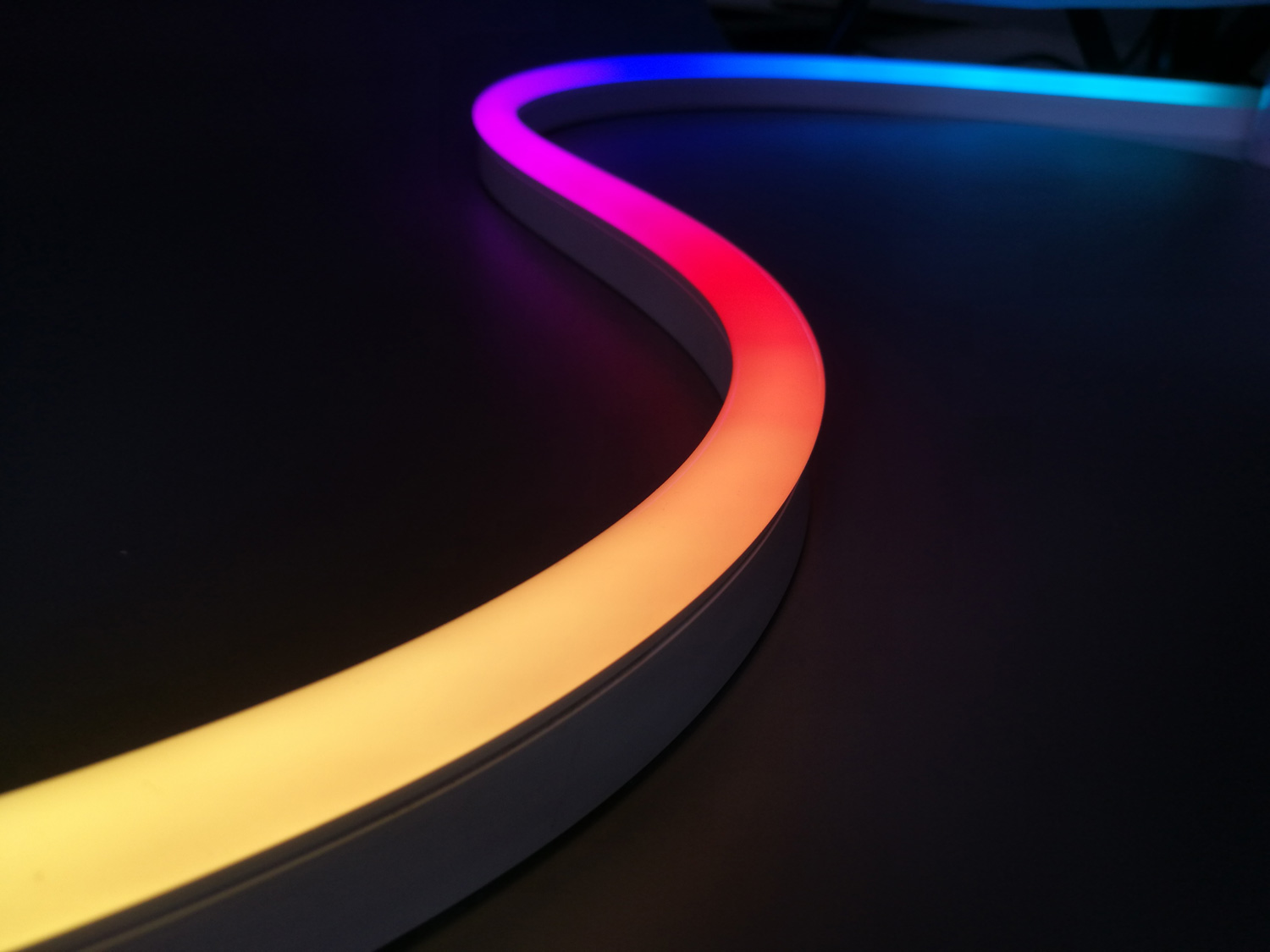

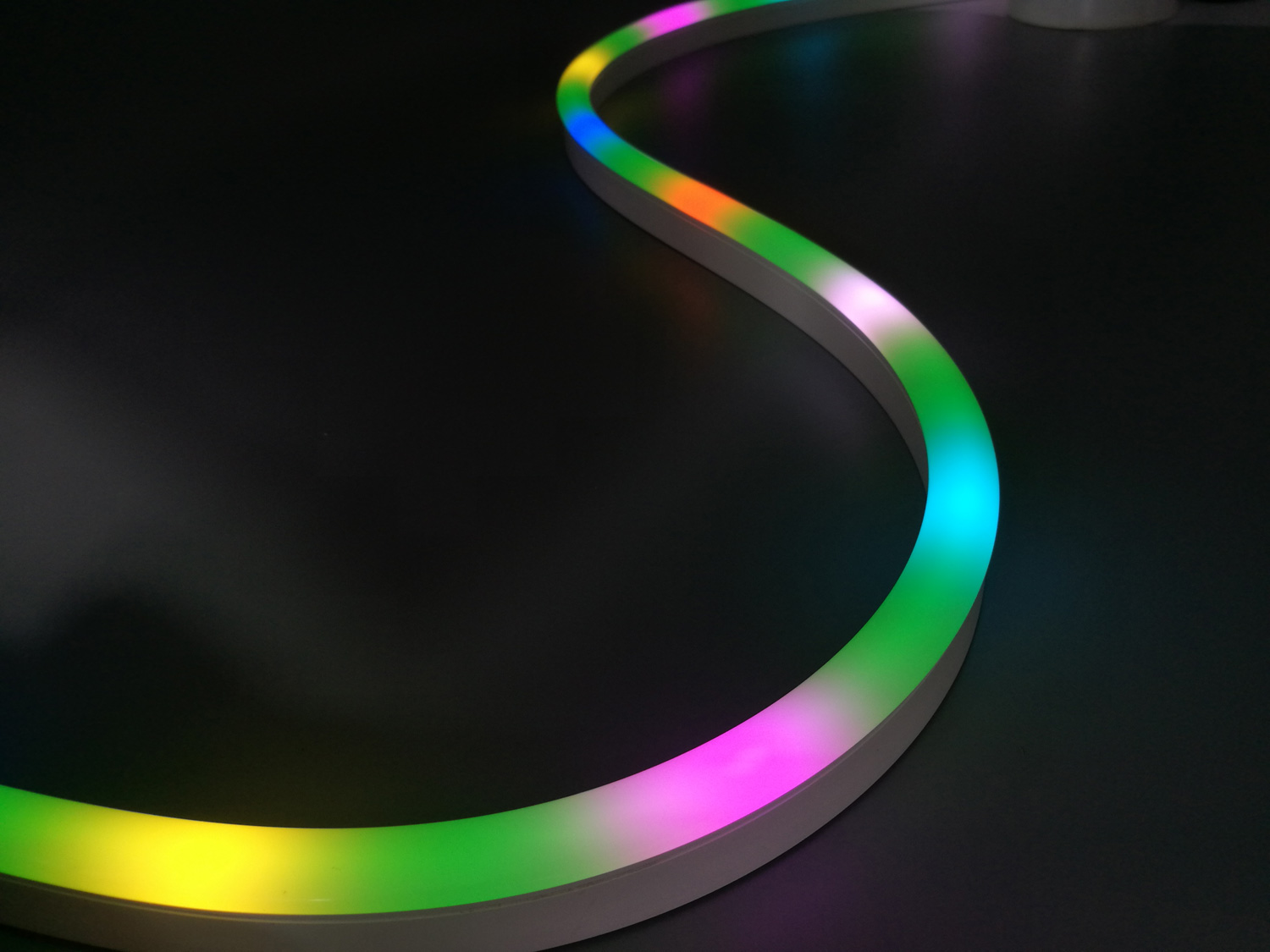

◆ High performance flexible linear neon light are Ip67 protected.

◆ It has efficient heat dissipation,brilliant color fidelity and is highly resistant to external influence due to it’s high quality, fully encapsulated finishing and silica’s stable performance compared to other materials.

◆ They have been extensively tested in numerous tests and provides robust resistance to salt, water, UV radiation,abrasion and chemicals.

◆ As a result, this led neon light is ideally suited for numerous interior and exterior applications: from wellness,garden and landscaping, through to architectural lighting,maritime lighting and many more.

1. Fully encapsulated, high quality and fully flexible LED strips with waterproof ratings Ip67.

2. Effective heat dissipation.

3. Compact dimension of only 6*12mm.

4. High efficiency with DeRun flexible high efficiency LED strip.

5. Resistant against water, chemicals, UV radiation and abrasion.

6. Small bending radius of only 15mm.

7. Non-toxic environmental protection, food grade silica just like baby pacifier.

8. Fire-protection rating V1.

9. Silica molecular structure stability ensure the coating yellowing resistant and no any changes for many years.

10. Mechanized production ensure high produc????on efficiency and avoid manual errors.

11. Punching end cap makes waterproof rating more high,give betier protection to soldering pad and it looks more beautiful.

12. 100% pure copper in FPC and high performance stable silica ensure a long LED lifetime.

Business premises lighting/Linear led lighting/Exhibition led lighting/Display led lighting/Bar led lighting/Home led lighting/Office led lighting/Led retail lighting/Accent led lighting/Pool led lighting/Architectural lighting/Led strip fixtures/Decorative lamp for outdoor lighting/ad. signs

| Item No. | CCT | Length (mm) | LED QTY | Power (W/M) | Input voltage (V) | Lm/m | Beam angle | IP | CRI | Work Temperature | Warranty | Dimension |

| LG10S1225-WW | 3000K | 1000 | 120 | 14 | DC24V | 330 | 170° | IP67 | 83 | -20~45℃ | 3 Years | 12*25mm |

| LG10S1225-NW | 4000K | 1000 | 120 | 14 | DC24V | 380 | 170° | IP67 | 83 | -20~45℃ | 3 Years | 12*25mm |

| LG10S1225-W | 6000K | 1000 | 120 | 14 | DC24V | 430 | 170° | IP67 | 83 | -20~45℃ | 3 Years | 12*25mm |

| LG10S1225-R | RED | 1000 | 120 | 14 | DC24V | / | 170° | IP67 | / | -20~45℃ | 3 Years | 12*25mm |

| LG10S1225-G | GREEN | 1000 | 120 | 14 | DC24V | / | 170° | IP67 | / | -20~45℃ | 3 Years | 12*25mm |

| LG10S1225-B | BLUE | 1000 | 120 | 14 | DC24V | / | 170° | IP67 | / | -20~45℃ | 3 Years | 12*25mm |

| LG10S1225-RGB | RGB | 1000 | 60 | 14 | DC24V | / | 170° | IP67 | / | -20~45℃ | 3 Years | 12*25mm |

Prepare the screws and fixed clips

Adjust the fixed clips to the Appropriate Place, use a screwdriver to fix the screw.

Put the light emiting surface Upwards, then insert the led strip Into the fixed clips.

Fix neon strip completely into the Fixed clip. LED Strip surface must be parallel to the top edge of fixed Clip.

| Type | ItemNO. | Neno Flex size | Carton size | Esdbag | Weight/Carton | Quanity/Carton |

| Neon Strip | LG10S1225 | 26x26cm | 30x60x60cm | 28x28cm | 0.55kg | 12kg |

| No. | Fault phenomenon | Possible reasons | Solutions |

1 |

All LEDs dark or discoloration | No power supply from driver | Power delivery |

| Strip with reverse polarity | Correct wiring | ||

| External power supply bus short circuit,switching supply automatic short circuit protection power | Excluding short-circuit fault, re-transmission | ||

| Power fuse burned | Replace fuse | ||

2 |

Parts led units dark or discoloration | No power supply from parts of driver | Check the power supply system, troubleshooting |

| Part of the light string supply line error | Check the power supply circuit, troubleshooting | ||

3 |

Uneven lumen output or short brightness | Overload power | Add power |

| Switching power line lossy | Bold power wires, or adjust the power supply position(the distance light with closer position)Make sure the line voltage into the lamp every five meters in 95% of the rated voltage of the above | ||

| Excessive number of light strings connected | Adjusting the quantity of each supply branch of the lamp,Meet the requirements of each power supply circuit with the largest lamp | ||

| 4 | LED flicker | Bad wiring contacts | Find the bad element point, troubleshooting |

5 |

Individual LED dark | Electrostatic breakdown | Discover the associated electrical and well grounded,replace the SMD. |

| Induction equipment breakdown (or leakage) | Discover the associated electrical and well grounded,replace the SMD. |

● Please use 24VDC isolated power supply to drive the led strip, and the constant voltage source ripple less than 5%. Can't step-down the power by resistancecapacitance and nunisolated power supply driver led strip, etc.

● To ensure the longevity and reliability of the strips, please do not bend the arc diameter 60mm or less, do not fold to avoid damaging the lamp beads or broken.

● To ensure the life and environment of lights, in the use of force can not pull the power cord to avoid damage to prohibit collision LED lights.

● During the installation of positive and negative atiention to the power cord, do not pick the wrong voltage power supply and the product are the same, so as to avoid damage to the product.

● LED lights should be stored in dry sealed environment, the proposed storage period should not be too long before using unpacking, the working temperature: -20 ~ + 45 ,Storage temperature: -0 ~ + 60 , not waterproof lights band indoor use, relative humidity ℃ ℃ ℃ ℃ not higher than 70%.

● In practical applications, the power supply should leave 20% margin (recommend using only 80% of the power) in order to ensure a sufficient amount of voltage drive products

● Do not use any acidic, alkaline adhesive securement products (including not limited to glass, plastic, etc.)