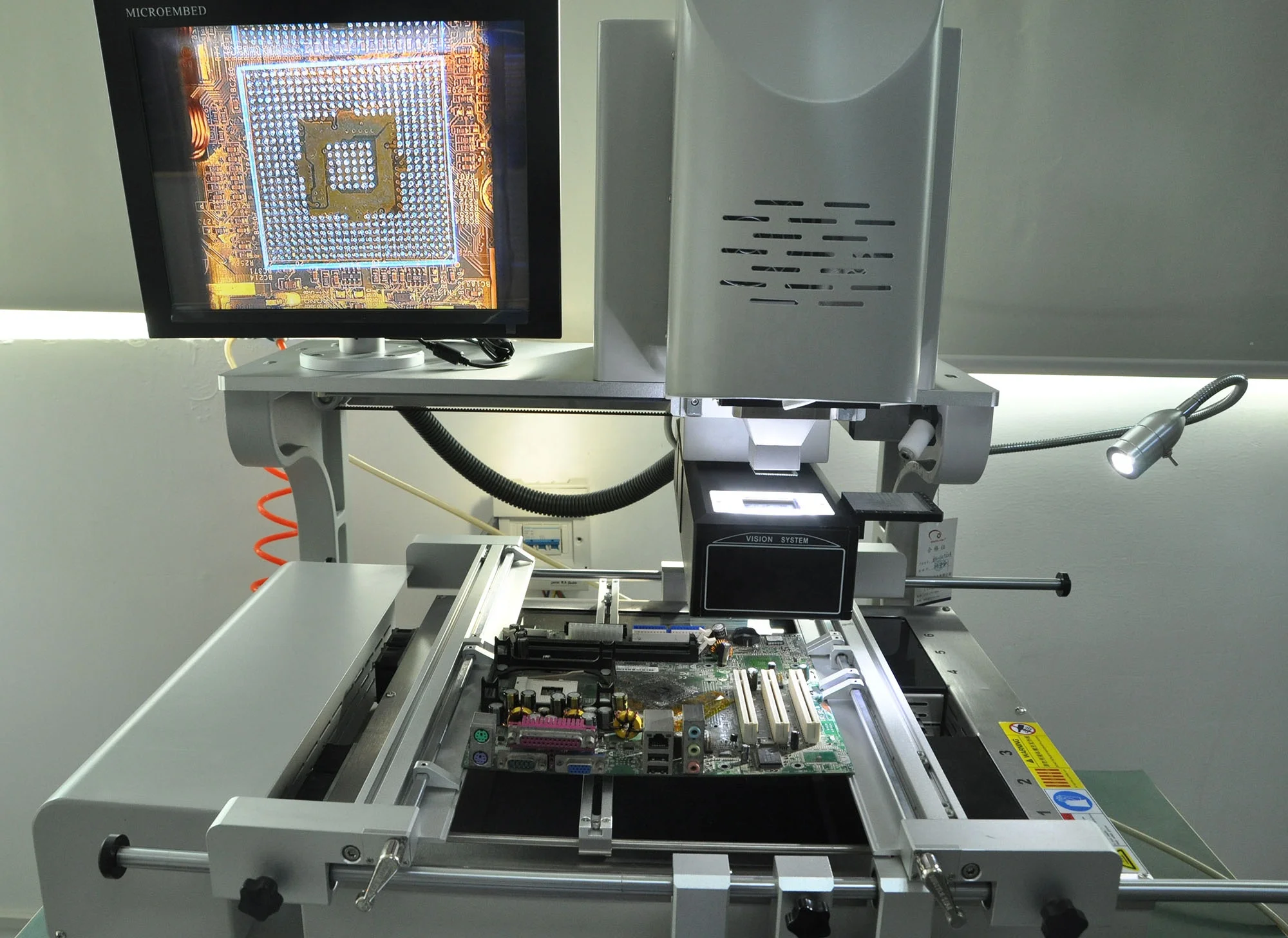

ShuttleStar RW-E6250U large rework station

RW-E6250U adopts the integrated design of hot air head and mounting head, automatic material absorption, automatic welding, automatic dismansoling, automatic discharge (patent number: ZL200720127185.8); embedded industrial control computer, PLC control, temperature curve, real-time display, temperature measurement curve analysis; and can be compared with the historical storage curve; heat can be entered in the process. The curve analysis, setting and correction of the process parameters can store the mass temperature parameters and the heating counterpart parameters. The camera has the function of splitting, amplifying and tuning, including the color difference resolution, auto focusing and software operation, and can be operated by the rocker. The upper and lower hot air head can be moved at any position in the preheating area of the bottom of the large IR. It is suitable for BGA to rework in different positions on PCB; the lower heating area adopts the infrared hot air mixing heating mode, and the nitrogen gas interface is reserved, and the BGA rework process can be completed under nitrogen protection, and it has the function of nitrogen saving, and it can save more cost under the guarantee of the reliable repair quality (patent number: ZL200920001515.8).

led light to replace fluorescent tube home depot 6250U led light fixtures replace fluorescent

LED lamp repair led light repair LED bolb repair

| PCB & Component Requirements | |

| PCB Maximum Size | 538mm x550mm |

| Max Processing Area | 80mm x 80mm |

| Max PCB Thickness | 0.5~4mm |

| Max Component Size | 70mm x 70mm |

| Min Component Size | 4mm x 4mm |

| Max Component Weight | 80g |

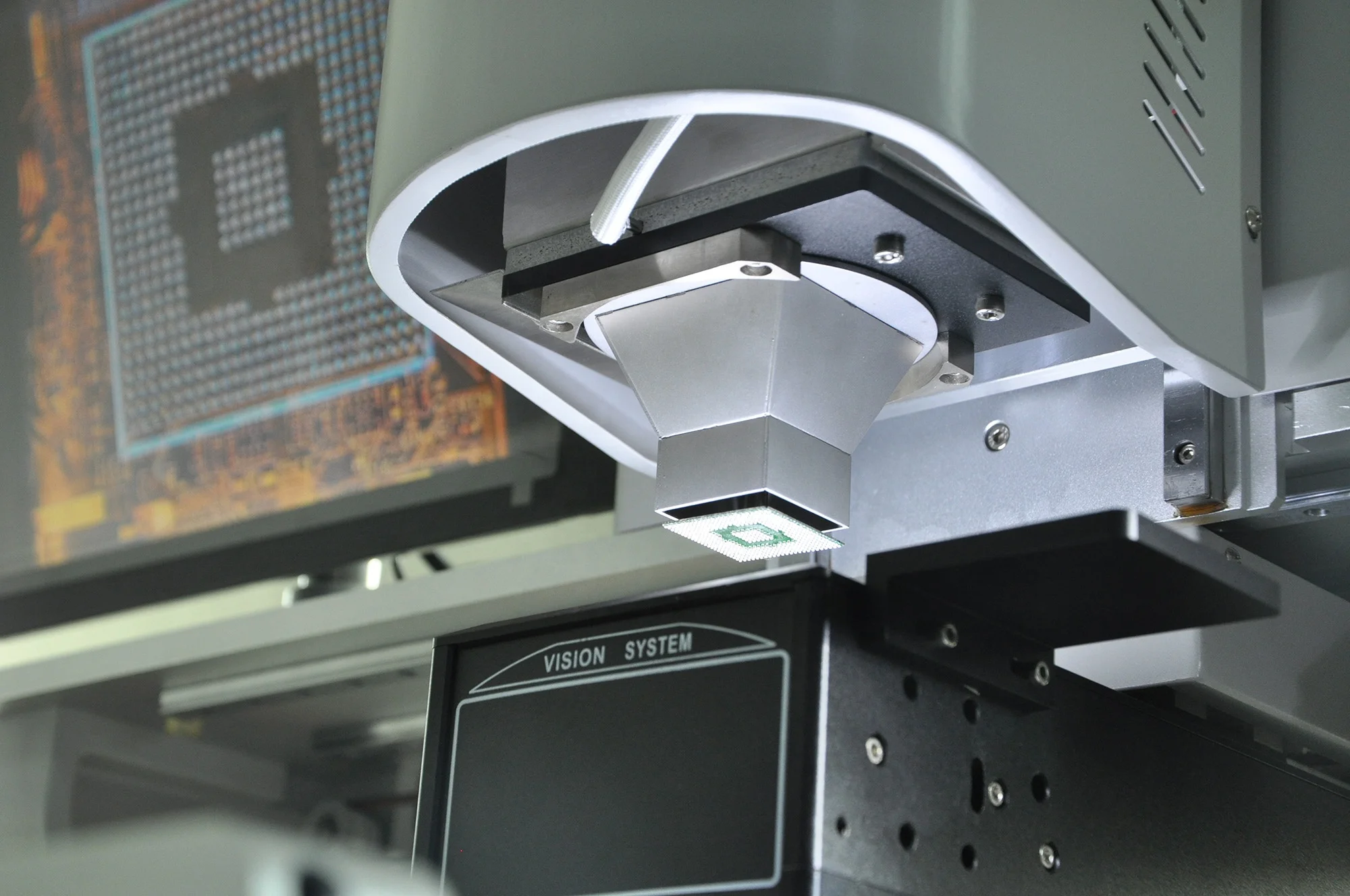

| Vision System Specifications | |

| Max Range of Vision | 40mm x 40mm |

| Min Pitch | /0.30mm |

| Micrometer Adjust Range | Front/Rear ± 10mm Left/Right ± 10mm |

| Rotation Angle | 360° |

| Thermal Specifications | |

| Max Hot Air Head Temp. | 350° C |

| Max Lower IR Heat | 450° C |

| Heat Control Adjustment | 16Stage Programmable Temperature Settings |

| Upper heater power | 2000W |

| Lower heater power | 1200W |

| Bottom IR heater Power | 4900W |

| Dimensions & Power Requirements | |

| System Dimensions | 818mm (L) 950mm (W) 1020mm (H) |

| Weight | Appox 130Kg |

| Power Requirements | 3 Phase, 380VAC, 50/60 Hz, |

| Air Supply | 3~8kgf/cm,95L/min |

1. Are you a trade company or a manufacturer

We are a factory,which not only sales our own brand products and also accept the OEM/ODM service according to customer’s demand.

2. How about the package ? Is it safe during the delivery ?

All the machines are packed by standard strong wooden carton with foam inside.It is safe when shipping.

3. What is the delivery terms ? What is the lead time or when will the machine arrrive us ?

We will ship the machine by DHL,Fedex, UPS,etc.Or by Air to your airport or by Sea to the seaport.

Average lead time is around 10 days,it depends on What machine do you want to buy.

4. Do you provide the Warranty ? How about the after sales service ?

1 year warranty free for spare parts, Whole life technicial support.

We have professional after sales team, if any question, assistant videos are also provided in after-sale service.

5. If we come to your factory, if you will provide the free training ?

Yes, warmly welcome you to visit our factory, we will arrange the free training for you.

6. What is the payment terms ?x ray machine bga x-ray inspection x7600

We accept the payment terms: Bank transfer, WesterUnion, Moneygram, etc.

For more info please feel free to send us your inquiry or contact us via following info:

Shenzhen Shuttle Star Technology Co.,Ltd.

Lucas Lu business manager

Tel: +86 755 2751 2579

Mobile/Skype/Whatsapp: +86 181 6572 4375

Wechat: LucasLu1994