X-Ray Solution X-1200 LED PCB Strip Version

Microfocus X-Ray Inspection System Manufacturer

Microfocus X-ray inspection machine X-1200 introduction:

X-ray inspection machine X-1200 working principle:

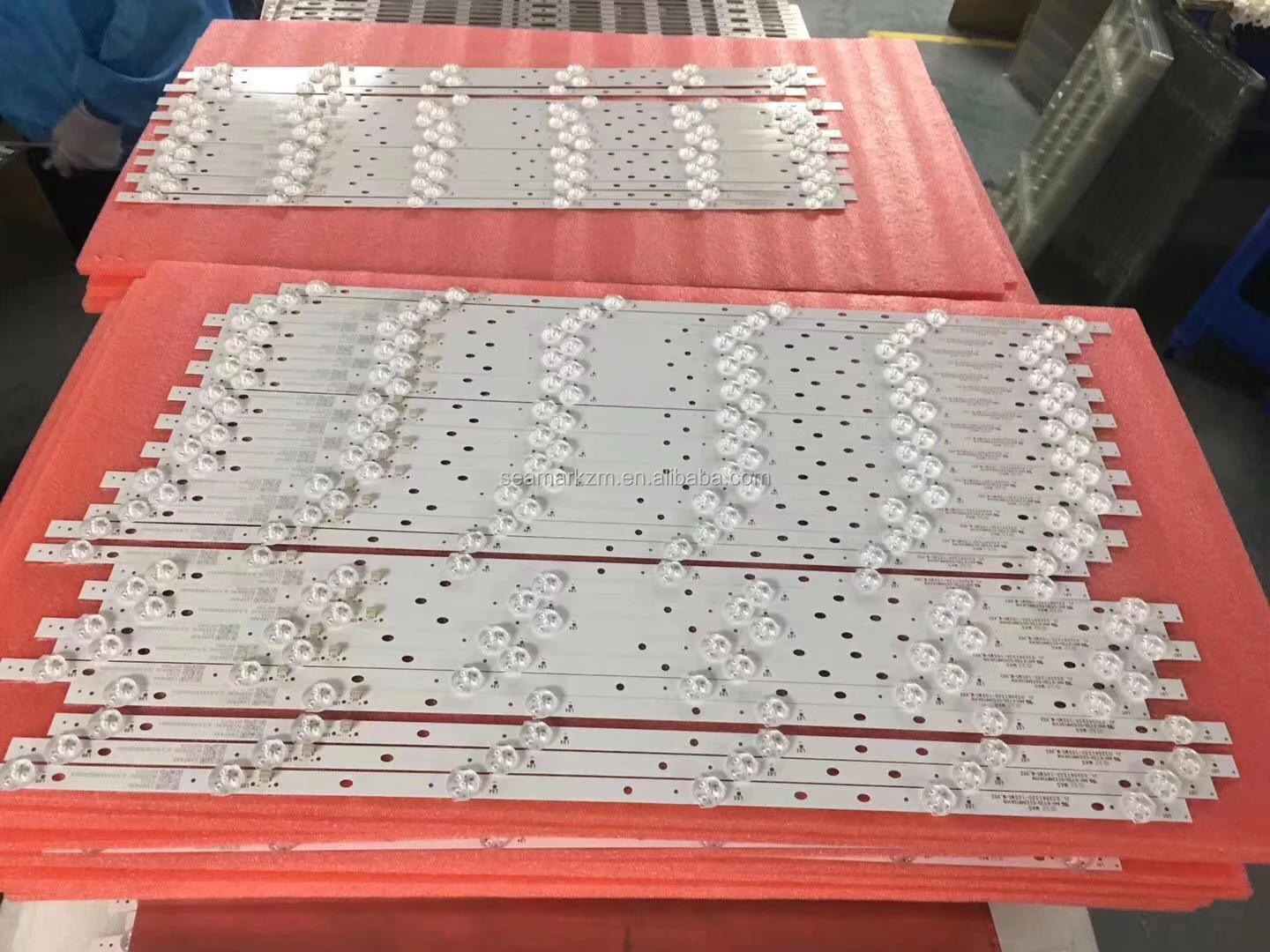

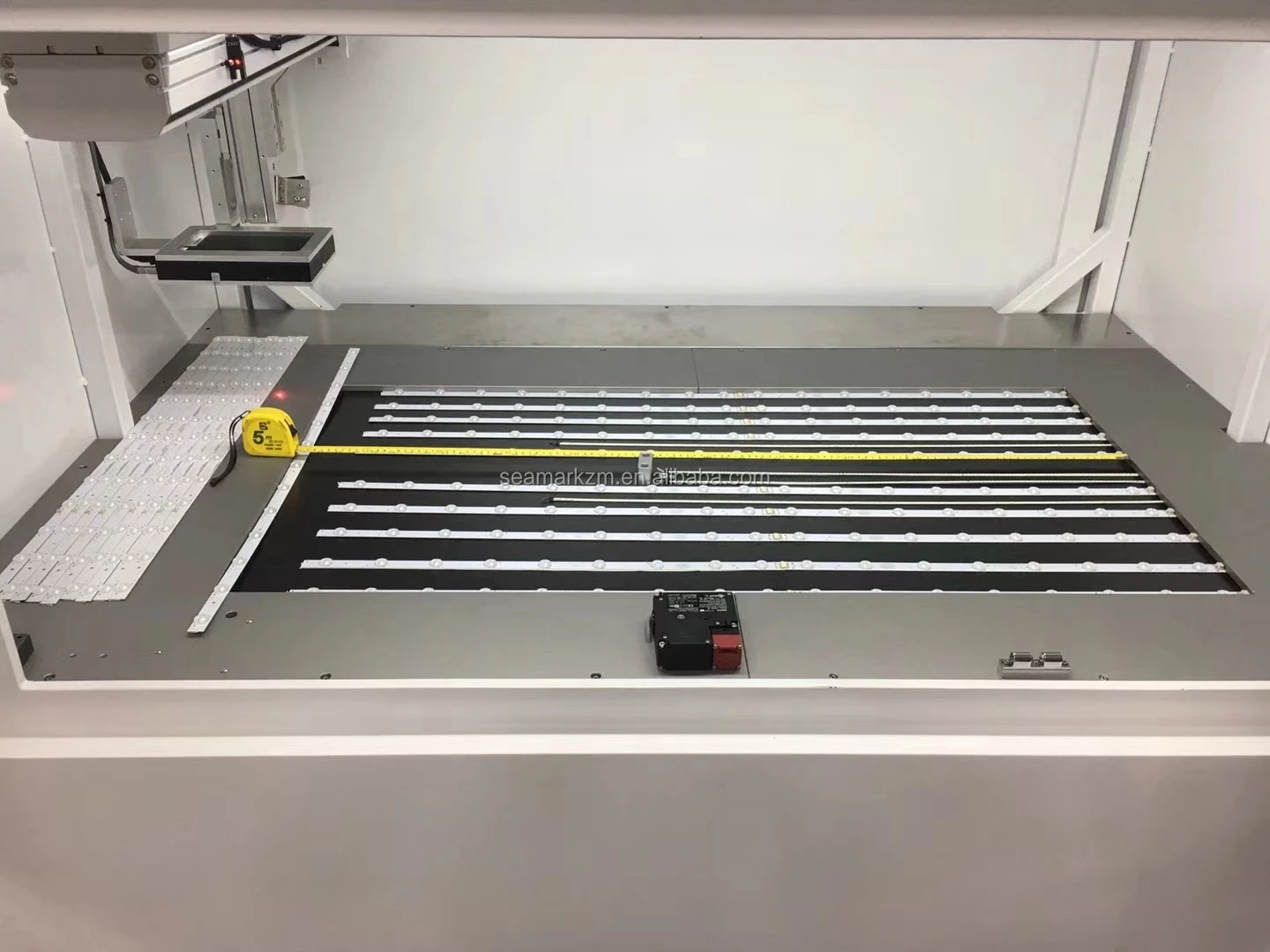

TV backlight LED strip, PCB circuit board: The upper detector and the lower X-ray tube are used for synchronous movement. The stage adopts a fixed structure, and the LED light strip and PCB circuit board with a length and width of 1200mm*600mm can be placed. Lamps, dots, holes, etc. can be effectively detected at any position within this platform.

Large inspection area: 1200*600MM.

It is specially designed for the LED TV backlight led stripe manufacturers/ Factories to inspect the 1200mm length led strip welding quality.

Seamark X-1200 has the most competitive price for you!

X-1200 on the 2018 Nepcon Exhibiton:

X-ray machine X-1200 Hardware technical parameters:

Hardware | X-ray tube | X-ray tube type | Closed microfocus X-ray source |

X-ray tube voltage | 90kV | ||

X-ray tube current | 200uA(Software limit 89uA) | ||

X-ray focal spot size | 5μm | ||

Detector | Type | HD digital flat panel detector (FPD) | |

Imaging area | 50mm*50mm | ||

Pixel matrix | 1176*1104 pixels | ||

Magnification | 800X | ||

Detection speed and accuracy | Repeated test accuracy | 3μm | |

Software detection speed | 3.0s/ Inspection point (excluding loading and unloading movement time) | ||

Stage | Effective detection area | 1200mm*600mm | |

Load capacity | ≤10Kg | ||

CNC motion mode programming function | Test parameters for different products can be stored in categories and called at any time. You can set the detection route or sequence of one or more products, and the program automatically completes the detection and stores the photos. | ||

Operating platform | With mouse, keyboard, 2 operating modes, any choice | ||

X-1200 detection effect photos:

BGA Voids Solder bridge

LED Soldering Voids PTH

Seamark X-ray leakage amount: ≤1 u Sv/hr

Workshop for the X-ray inspection machine:

Seamark offer free training and installation for all types of Microfocus X-ray inspection machine.

X-ray Machine FREE Training in:

Singapore, Portugal ,Germany,Canada, India, China etc.

WHY CHOOSE US:

1. 13 years experience of LED BGA SMD rework station and X-ray inspection machine.

2. All X-RAY models with CE and FDA approved.

3. High reputation around the world.

4. Professional service and technology support.

5. Competitive price with good quality.

Welcome to contact us to discuss with us the X-ray machine you want, we’ll be glad to accept customized order.

Related machine:

X-6600 SMT X-ray X-5600 mini X-ray ZM-R6200 BGA rework

Package of microfocus X-ray inspection machine X-6600:

1. Standard export wooden package for X-ray inspection machine.

2. Delivery within 10 business days after payment confirm;

3. Shipping by sea to your nearest seaport.

4. Loading Port: Shenzhen.

Shenzhen Zhuomao(Seamark ZM) Technology CO., Ltd, a 13-yearprofessional manufacturer and exporter of LED BGA rework station, Glue dispensing robot, X-ray inspection machine. We are a high-tech enterprise including R&D, production, Sales and After sales service.

Currently, our machine have been sold around Europe, Asia, Australia, Oceania and Southeast Asia, Middle East and other countries and regions. We are the vendor of FOXCONN, HUAWEI, FLEX, NVIDIA, LENOVO, PANASONIC, HISENSE, SANMINA-SCI, GIGABYTE, SAMSUNG, and so on.

High quality assurance is our task and also what we are doing now.

Factory photo:

Exhibition:

Representative customers:

1. About the Package, is it safe during the shipping ?

The X-ray inspection machine are packed in solid wooden box with foam, sticks and band to fix inside. It is safe enough when shipping.

2. About the Transportation, which way and how many days will the machine arrives?

Because the X-ray machine is a big equipment. Normally by sea or by air to your nearest seaport or airport, 5~10~20~30~40 days to arrive. (different country different time)

3. About the Warranty, how long and how to do the after-sales service ?

1 year warranty free for spare parts, and whole life technical support.

We have professional technical team, for any question, assistant videos are also provided.

4. About the Operation, if I have no experience, can I also operate it well ?

Our X-ray inspection machine is designed to use easily, normally it will take you 2-3 hours to learn how to operate, if you are a technician, it will be much faster to learn. We will provide the English user manual for free , and the operation video is available.

5. About the Training, will you provide the free training ?

Yes, we will arrange the free training and installation service for you.

6. About the Payment, which way is better ?

We accept the payment terms: T/T, Bank transfer, Western Union, Money gram, PayPal, L/C etc. Others payment ways is negotiable.

Contact information:

Juliet Su Sales Representative

Website: www. seamarkzm.com

E-mail: sales7 @zhuomao.com.cn

Mobile/ Skype/ Wechat: +8618922798754