Introduction

Cylindrical battery automatic injection machine is a high precision equipment with high efficiency and high performance. The operation is simple, practical and reliable. The machine adopts humanized design, can effectively reduce the labor intensity of workers, can effectively improve the process control, is the preferred equipment for the production of cylindrical batteries.

Specification

Voltage | 220V, 50Hz |

Rated power | 1.0KW |

Working Pressure | 5-6 kgf/cm2 |

Weight | about 200 Kg |

Efficiency(capacity) | about 40 pcs/min (reference volume 5g) |

Dimensions | 1500mm(L)*1000mm(W)*700mm(H) |

Filling accuracy | ±0.1g |

Suitable battery type | Suitable for various battery sizes by changing the fixture

|

Battery number for each tray | Can be customized according customer's need about the machine capacity

|

Main structure of equipment

1.Main Frame for Injection

The stepping motor drives the displacement and positioning step by step to the top of each battery to realize liquid injection. Human-machine friendly interaction, intelligent control of injection parameters, easy to set.

2.Injection Absorption Part

Two vacuum absorption chambers are arranged with pallets alternately injected and absorbed. The liquid is injected into the left or right absorption box by placing the tray manually.

3. Injection Pump Part

Item | Specification |

Accuracy | Less than 1% at 4ml/s, ±0.1g |

Adjustable range | The adjustable range of injection volume is 0.1-1.5g |

Injection pump | Adopting rotary valve structure, without dynamic sealing ring, avoiding the phenomenon of air bubbles in one-way valve injection pump Special high wear-resistant ceramic pump head, high precision, corrosion resistance, easy maintenance, easy cleaning, reliable and durable life, key accessories using imported components

|

Control mode | External PLC control Automatic control or manual operation of external pedal switch With counting function |

4.Electrical Part:

Mitsubishi Electric Procedure product monitoring, the whole machine is connected with multiple induction switches, equipped with a safety screen; equipment abnormal situation automatic alarm, improper operation, automatic stop. Equipped with "emergency stop" operation, the equipment can stop operation at any time as required.

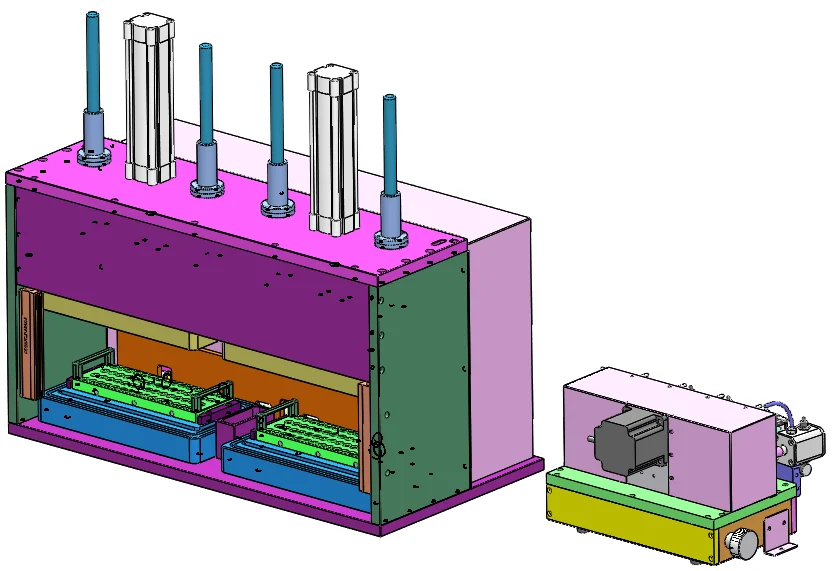

Product Images

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to production season and order quantity.

1. Which procedure to secure your Quality?

1.Order processing?

2. Shipping methods?

1 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

2 Responsible for the damage during the shipping process, will change the damaged part for you for free.

3.Order tracking?

An online order can be tracked by login to your account. Please allow 24 hours after order is shipped to see logging details.

If you need a tracking number for your order, please send an email to us with your order/invoice number.

4. Import/export tax, duty, GSM, Customs Clearance, and etc?

All import/export related expenses are the sole responsibility of the buyer; charges will vary from country to country. Please consult with your local import experts or transportation carrier for more details.

5.Lost or Stolen packages?

Please report all lost or stolen packages to us at the earliest possible time. An investigation will be open soon after reporting the incident to us, and a final ruling will be issued by the carrier for the claim after 10-15 business days. A replacement package will be sent as soon as the claim is accepted by the responsible carrier.