Features

VTC-16-SM is a High Power Desktop Magnetron Plasma Sputtering Coater with a water cooling 2" target head, water chiller and rotatable sample holder. The coating unit is designed for coating all metallic films up to 4" diameter wafer including Zn, Al, Ti and carbon light film at an affordable cost. One Al target is included for immediate use. (Since May 18, 2015, this product no longer comes with vacuum pump in standard package.)

Technical Parameter

Input Voltage | · 220 VAC 50/60Hz · 110 V power is available by using a 1000 W transformer (15 A fuse). The transformer is sold separately. |

Output Power

| · 1600 VDC · 250 W · 150 mA max. · Built-in over current protection (>150 mA) |

Specimen Chamber |

· Quartz glass tube, 165 mm OD. X 150 mm ID x 250 mm Height |

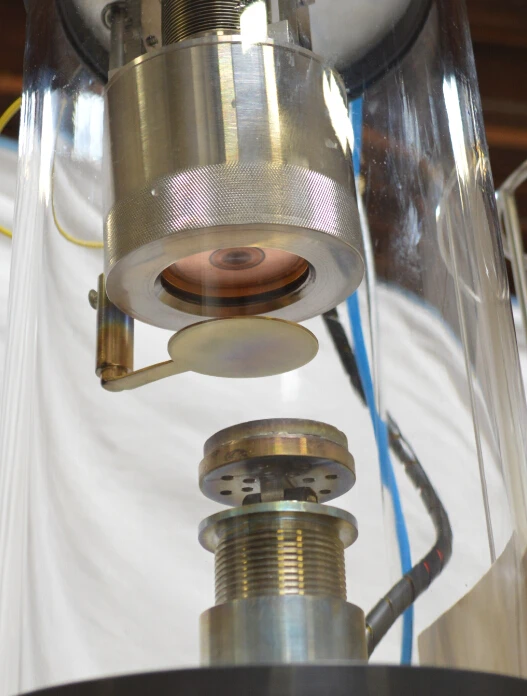

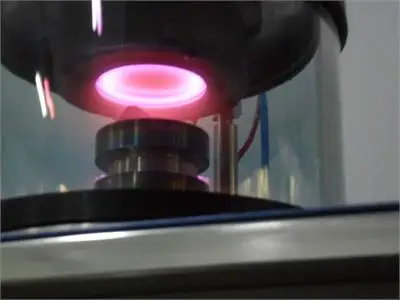

| · 2“ flexible magnetron sputtering head with water cooling jacket is included (Fig.1) · One 50 mm Dia stainless steel sample stage is rotatable from 0 - 5 RPM · One manually operated shutter for target protection. (Fig.2) · Sputtering head holder is available for holding sputtering head while non-operation. · The distance between the sputtering head and sample stage is adjustable from 60 - 100 mm. · Max Coating area: 4" diameter max. · One Air Cold Recirculating Water Chiller 10 L/min Flow is included for cooling sputtering head. (Fig.6) · |

Control Panel | · 6" color touch-screen control panel with PLC integration for easy operation · One panel for all parameters monitor and control: vacuum, current. |

Ultimate Vacuum Pressure | · Built-in KF25 vacuum port · The system requires an Ar gas tank with pressure regulator. (not included) · < 1.0E-2 Torr by Vane vacuum pump (not included) for Au, Ag, Pt, Cu, Mo targets (not sensitive to air) · < 1.0E-5 Torr by Turbomolecular pump (not included) for Al, Mg, Li, Lr, Ti, Zn targets (sensitive to air) · The lowest vacuum may reach < 4.0E-6 Torr by pumping overnight and baking |

Gas Atmosphere | · One needle valve installed to allow Ar gas inlet to achieve better plasma coating · The system requires an Ar gas tank with the pressure regulator (not included) |

| · One 2" Copper target is included for testing, Target size: 2" Dia.x 2.5mm. ·It also can coat Ag, Al, Cr, Ni, Pt, Ti, Sn, Li, Mg, etc. almost every kind of metallic material. · Warning : Aluminum , Chromium or Nickel Target can be coated by this machine, but please view the Recommend Coating Method before using. · Please using RF Plasma Magnetron Sputtering for coating Alumina |

Optional Film Thickness Monitor | · Film thickness monitor is optional at extra cost · Heatable sample stage up to 500°C is available upon request at extra cost · Flowmeter for accurate control gas inlet is available upon request at extra cost. |

Overall Dimension | · L 440 mm×W 330 mm × H 290 mm |

Net Weight | · 20 kg |

Shipping Weight & Dimension | · 160 lbs · 45" x 45" x 40" |

Compliance | · CE approval · NRTL Certification is available upon request at extra cost, please contact our sales representative for quote. |

Warranty | · One year limited with lifetime support |

Application Notes | · Warning: Sputtering head connects to HIGH voltage. The operator must wear gloves during operation · Make sure the target, sputtering head, substrate, and heating stage are clean before coating, need to use the sandpaper and alcohol to clean and fresh the Al or Nickel target each time using. |

Product Images

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to production season and order quantity.

1. Which procedure to secure your Quality?

1.Order processing?

2. Shipping methods?

1 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

2 Responsible for the damage during the shipping process, will change the damaged part for you for free.

3.Order tracking?

An online order can be tracked by login to your account. Please allow 24 hours after order is shipped to see logging details.

If you need a tracking number for your order, please send an email to us with your order/invoice number.

4. Import/export tax, duty, GSM, Customs Clearance, and etc?

All import/export related expenses are the sole responsibility of the buyer; charges will vary from country to country. Please consult with your local import experts or transportation carrier for more details.

5.Lost or Stolen packages?

Please report all lost or stolen packages to us at the earliest possible time. An investigation will be open soon after reporting the incident to us, and a final ruling will be issued by the carrier for the claim after 10-15 business days. A replacement package will be sent as soon as the claim is accepted by the responsible carrier.