Lab Scale Variable Speed 0.4L Ultrafine Grinding Bench Top Planetary Ball Mill Grinder Machine

I. Explanation and Principle

Planetary Ball Mill is designed for mixing, fine grinding, and preparing small volume high-tech material production, which features with small volume, high efficiency, low noise and Lock clamps. If choosing with optional vacuum jar, it can grind samples under the vacuum condition or filled with inert gas. The product is extensively used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry, Medicine, and Environmental Protection, etc.

Working Principle:

When the plate rotates, the tank axis makes the planetary rotation in opposite directions and the balls in the tanks grind and mix samples in high-speed movement. The product can smash and blend various products of different materials .

It has 3 types of mill methods:dry mill; wet mill ; vacuum mill.

Two or four grinding jars can work together.

(Note: granularity of grand products is dependent on the material properties, size, and quantity of milling media and processing time. According to customer's feedback, minimum granularity can be as small as 0.1 um).

2. Application Field

The product is extensively applied in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

It's widely used in research institutes, universities, enterprise laboratories and small batch producing manufacturer.

3. Sample Testing

1.Material: Chinese herbal medicine

2.Grinding tank: zirconia jars

3.Grinding method: dry

4.Grinding Speed: 500rpm (rotation)

5.Selected equipment: XQM-2

6.Grinding tank volume: 500mLx4

7.Grinding time: 1hour

8.Discharge particle size:Soluble in water

1.Application: Abrasives and abrasives;

2.Material: glass powder;

3.Particle size of feeding: 0.5mm;

4.Feeding amount: 2000g;

5.Material properties: brittle;

6.Customer requirements: 35 μ m;

7. Sequential analysis: particle size analysis

8. Selected equipment: planetary ball mill XQM-4;

9.Jar and ball configuration: corundum tank with zirconia ball;

10. Operating parameters: rotation 560 rpm, grinding time of every 20 minutes in positive and reverse rotation;

11. Grinding results: 99% < 35 μ M;

12.Results (suggestion): the XQM-4 planetary mill can be used to grind glass powder

Specifications

|

Model |

Capacity |

Specification of milling tank |

Qty |

|

XQM-0.2 |

0.2L |

50ml |

2/4 set |

|

XQM-0.4 |

0.4L |

50ml-100ml |

2/4 set |

|

XQM-1 |

1L |

50ml-250ml |

2/4 set |

|

XQM-2 |

2L |

50ml-500ml |

2/4 set |

|

XQM-4 |

4L |

250ml-1L |

2/4 set |

|

XQM-6 |

6L |

lL-1.5L |

2/4 set |

|

XQM-8 |

8L |

1L-2L |

2/4 set |

|

XQM-10 |

10L |

1L-2.5L |

2/4 set |

|

XQM-12 |

12L |

1L-3L |

2/4 set |

|

XQM-20 |

20L |

2L-5L |

2/4 set |

|

XQM-40 |

40L |

5L-10L |

2/4 set |

|

XQM-60 |

60L |

10L-15L |

2/4 set |

|

XQM-100 |

100L |

20L-25L |

2/4 set |

Model selection guidance

|

Model selection of planetary ball mill |

Nature of abrasive material |

|

Vertical planetary mill |

Grinding of general materials, no special requirements |

|

Comprehensive planetary mill or horizontal planetary mill |

The material is easy to sink and bind |

|

Double planetary mill |

Ultra high speed and ultra-fine grinding are required |

|

With air cooling device or liquid nitrogen device |

The grinding process is hot and needs to be cooled |

|

Equipped with vacuum ball milling tank |

Easy to oxidize, requiring vacuum environment or atmosphere protection |

|

With heating device |

High temperature grinding required |

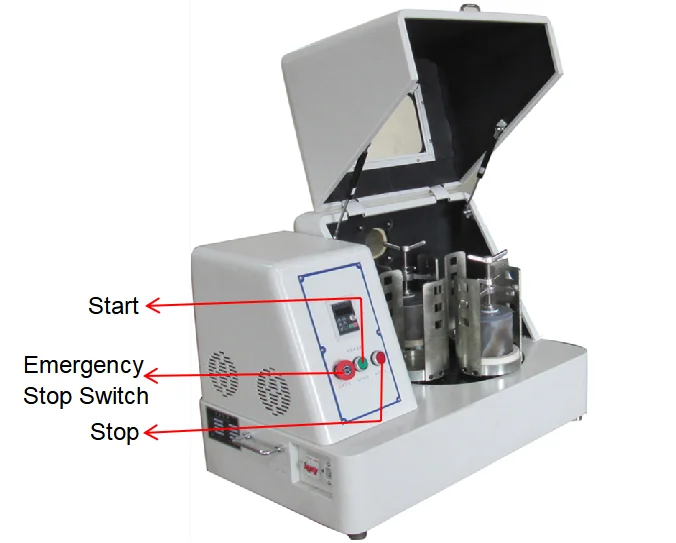

Product Images

Related Mill:

Full Directional 360 Degree Rotation Planetary Ball Mill Laboratory Bead Mill

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.