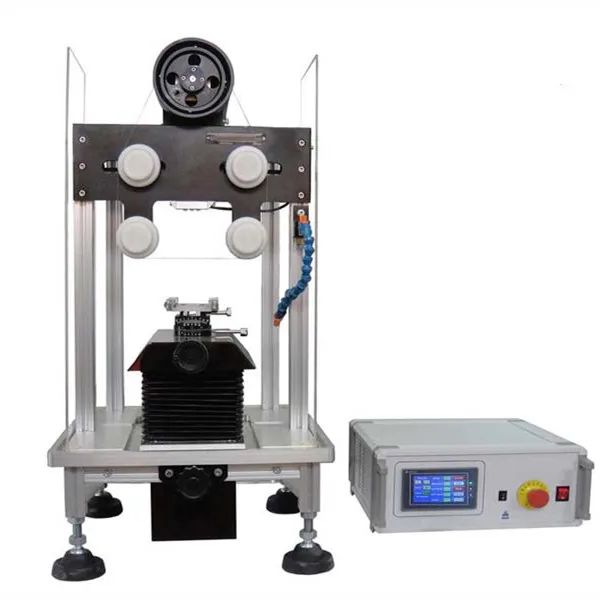

Desktop Precision Diamond Wire Saw With Touch Screen Control for Fragile Crystals and TEM or IC Sample Cutting

Features

STX-202A (STX-202A is an upgraded version of STX-202 since Mar 2014 with additional auto-control Y-axis) is a CE certified, small precision diamond wire saw for cutting sample ≤ 2" diameter or square up to 50mm in thickness. It is designed to provide a smooth cutting for many kinds of materials, especially for fragile crystals and TEM or IC sample by using 0.28mm diameter x 15-meter long diamond impregnated wire. It is an ideal cutting tool for material research, TEM sample preparation, and IC failure analysis.

Specifications

|

Power |

Wire Saw Control Consol: Universal 110V or 240VAC 50/60Hz, 200W max. |

|

Structure |

Heavy-duty aluminum alloy structure with compact size automatically controlled Y-axis by the digital panel single wire swing cutting with adjustable wire length from 5-15mm (broken wire still can be used) Transparent plastic plates are included to prevent Coolant splashing Add an oil refill cup behind the forming tube (New design), please apply 10-15 drops Anti-Wear Oil before first-time use. Wire spooler motor, 3 Amps, Torque=1.8Nm |

|

Sample stage |

Z axis: 50mm, automatically controlled by the digital panel Y-axis: 50mm, automatically controlled by the digital panel Two dimension sample stage built in 360° degree horizontal rotating and +/-10° tilting vis manual operation Optional: 3 dimensions automatically controlled sample holder ( Y+Y +360° flat rotation ) is available upon request at extra cost.

|

|

Cutting parameters |

Feed Speed: 0.01 mm/min to 40 mm/min adjustable Back Speed: 1 mm/min to 100 mm/min adjustable Spooler spin speed: 1-260 RPM adjustable Cutting depth: 0.1 - 50mm Positional accuracy: +/- 0.01 mm Please click the picture left to see the samples cut by this machine |

|

Meteorite Sample |

Please click the picture below to view the meteorite samples that were cut by our wire saws.

|

|

|

Color touchscreen controller will set up wire travel speed, cutting speed along Z axis and cutting width along Y axis

|

|

|

≤ 15 meters used for each installation One spool of 0.30mm Dia x 20 meter length Diamond Wire is included for immediate use A Diamond Blade Dressing Stone is included for keeping the wire sharp. Optional: For slicing or dicing very brittle crystal, you may order 0.22 mm Dia. Diamond Wire. Note that 0.22mm Dia. The wire is very easy to break, please reduce feeding rate to the minimum. click the picture below to order spare diamond wires For longer wire life, please use LubeCool -150 Smart Solid Lubricant and Coolant

For better lighting, please consider a Fiber Optic Y-shape Dual Light Microscope Illuminator |

|

Wire tension system |

Standard: Steel spring wire tension system with break wire alarm |

|

|

One water pump is included for cooling diamond wire during cutting. (the pump voltage is the same as the saw voltage) You must use anti-corrosive oil or radiator water as coolant ( buy from any auto store ) Warning: must clean the machine after each cutting, especially using tap water as the coolant to prevent rust. |

|

Optional |

Swing & Rotation Sample Fixture: Such fixture needs an independent controller for its parameter settings such as swing frequency/ angle (±23°, up to 20 swings/min), rotating speed and rounds (30rpm max.) Higher cutting surface quality can be expected by swinging or rotating the specimen throughout the cutting process. The fixture will enhance cutting speed up to 2 times |

|

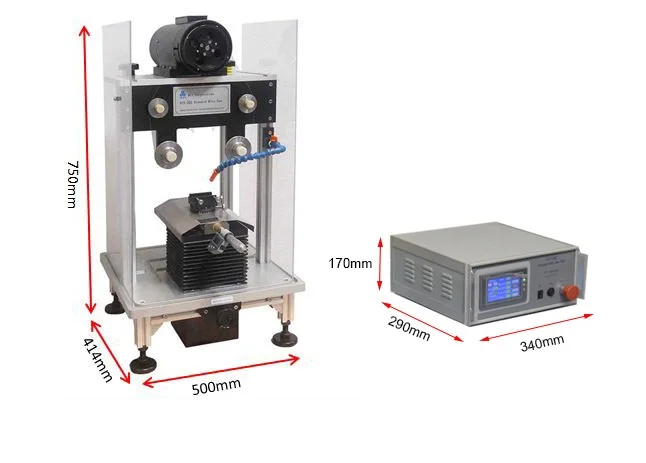

Product dimensions |

Saw: 414mm(L) × 500mm(W) × 750mm(H) Controller: 340mm(L) x 290mm(W) x 170mm(H) ( Click to enlarge the picture below for detail size ) |

|

Shipping dimensions |

48"(L) x 40"W) x 45" (H) |

|

Shipping Weight |

220 lbs |

|

Warranty |

One year limited with lifetime support, not including cutting wire |

|

Certificate |

CE certified. With additional certification fee, MTI can arrange NRTL to perform UL/CSA inspection and label the machine per customer's request. |

|

Application Notes |

The flow rate of coolant is adjustable by the valve in the blue feeding tubing. Please adjust it properly to improving cutting performance. Please use correct cutting fluid. Don't use tap water or any other fluid would cause corrosion of machine parts. Must clean the machine after each use.

|

|

Warnings |

It is required to use proper cutting fluid with the saw to prevent corrosion of the machine components. We strongly recommend you use oil-based coolant or lube cool lubricant with the water. Do not use tap water directly, the rust component is not part of the warranty. Do not overflush the sample stage, it may rust the Z-axis step motor. It is required to apply 10-15 drops Anti-Wear Hydraulic Oil (ISO 32) using an oil can(#19) before first-time use or continue working for 150 hours.

And limited amount of grease (general purpose grease will do) should be added to the motor shaft periodically, Never cut any materials without the use of proper cutting fluid. If you do so, serious damages can be caused by the spooler driving mechanism. For cutting the sticky materials such as non-ferrous alloy, epoxy, and plastic, you must sharpen diamond wire frequently. We suggest that cutting sample along with the included dressing stone (Glue sample and the dressing stone side by side and cut them together, this process will help keep the wire sharp enough for efficient cutting. Please clean the machine after the completion of each use. |

STANDARD PACKAGE:

|

No. |

Descriptions |

Qty |

Picture |

|

1 |

STX-202 diamond wire saw |

1 unit |

|

|

2 |

Electrical control box |

1 unit |

|

|

3 |

Control box cable with Identification cable number |

3 pcs |

|

|

4 |

Diamond wire Ø0.3mm x 20meter |

1 pc (installed) |

|

|

5 |

90-degree rotatable holder. |

1 pc (installed) |

|

|

6 |

Auto-tension wheel fixture |

2 pcs |

|

|

7 |

Two dimensions crossing vise |

1 pc |

|

|

8 |

Diamond wire Ø0.35mm x 20meter (for spare) |

2 pc |

|

|

9 |

Allen hex wrench M3, 4, 5 |

1 set |

|

|

10 |

Cross-head screwdriver |

1 pc |

|

|

11 |

Leading wheel (for spare) |

2 pcs |

|

|

12 |

Auto-tension wheel (for spare) |

2 pcs |

|

|

13 |

Resin Bonded Ceramics for Samples Holding (50 x 50mm) |

2 pcs |

|

|

14 |

Wax bar |

4 pcs |

|

|

15 |

Coolant tank |

1 pc |

|

|

16 |

Water pump (the pump voltage is the same as the saw voltage) |

1 unit |

|

|

17 |

Handle for spool |

1 unit |

|

|

18 |

Water splash guard |

4 pcs |

|

|

19 |

Oil can |

1 pc |

|

|

20 |

Power cord |

1 pc |

|

|

21 |

5A Fuse |

2 pcs |

|

|

22 |

Diamond Blade Dressing Stone |

1 pc |

|

|

23 |

Ø8mm polyurethane tube for coolant system |

1 pc |

Product Images

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.