Semi-automatic Electrode Winding Machine for Lithium Ion Cylinder Battery Production Line

Featuers

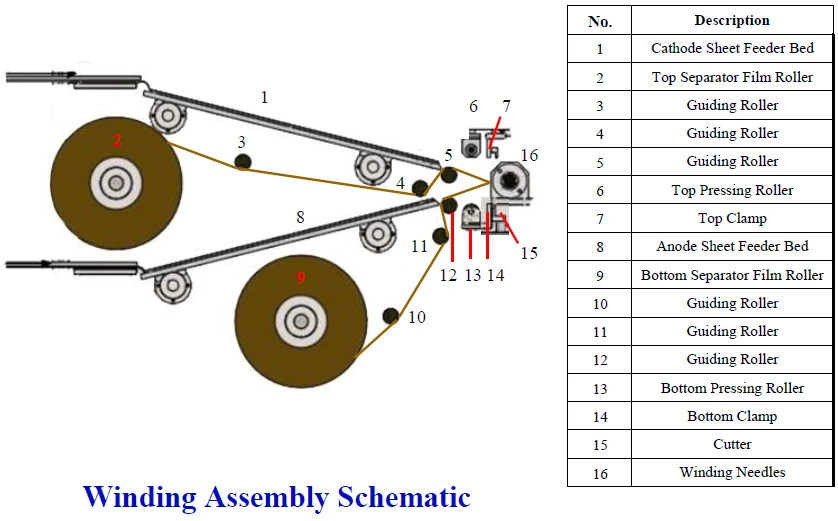

It is a semi-automatic winding machine for accurate assembly of single cylindrical cell cores (also known as “jelly roll”). Using this machine, cathode and anode films, separated by top and bottom separator films, are rolled up into a hollow cylinder casing for cylindrical battery applications. It is an ideal tool for the reliable and precise production of high-quality windings of electrode cores.

Specification

|

Features |

Color touchscreen control ·Winding motor direction control: forward and reverse switchable (manual mode) ·Adjustable tension (0 – 4 N) for both top and bottom separator films ·Vacuum-assisted, 1200 mm long feeder bed for accurate cathode/anode film positioning & feeding Automatic finish cut upon the completion of the configured number of rotations ·Suitable for cylindrical battery sizes such as 18650, 21700, 26650 and 32650 (jelley roll dia. 14mm~32mm; length 25~70mm) |

|

Input Power |

· Single phase 220 VAC, 50 / 60 Hz · 1 kW power |

|

Compressed Air

|

· Compressed air of 0.7 MPa is needed for the operation of this machine · Please note the air compressor is not included. |

|

Cathode / Anode Feeding

|

· Loading material: cathode / anode sheets, such as aluminum foil coated with LiFePO4 or LiCoO2 (cathode), and copper foil coated with graphite (anode) · Length range: < 1200 mm recommended (length of the feeder bed plus extension) · Width range: 25 – 70 mm (adjustable on feeder bed) · Thickness range: 100 – 300 μm |

|

Separator Feeding

|

· Loading material: separator film rolls, such as polyethylene (PE) or polypropylene (PP) · Length range: separator roll with a diameter < 250 mm · Width range: 25 – 70 mm · Thickness range: < 100 μm · Tension range: 0 – 4 N for both top and bottom separator films |

|

Winding

|

· Winding needle size: 3.5 mm OD · Electrode winding size: 14 – 32 mm OD, 25 – 70 mm in length · To wind an electrode core with a certain OD, a spreadsheet for calculating needed number of turns and electrode sheet length can be downloaded here · Winding speed: 0 – 400 rpm adjustable · Winding precision: < 0.5 mm edge roughness |

|

Size

|

· 1000 mm L x 700 mm W x 900 mm H |

|

Net Weight

|

· 150 kg |

|

Warranty

|

· Two years limited warranty with lifetime support · Rusting or damage due to improper storage conditions or maintenance is not covered by warranty |

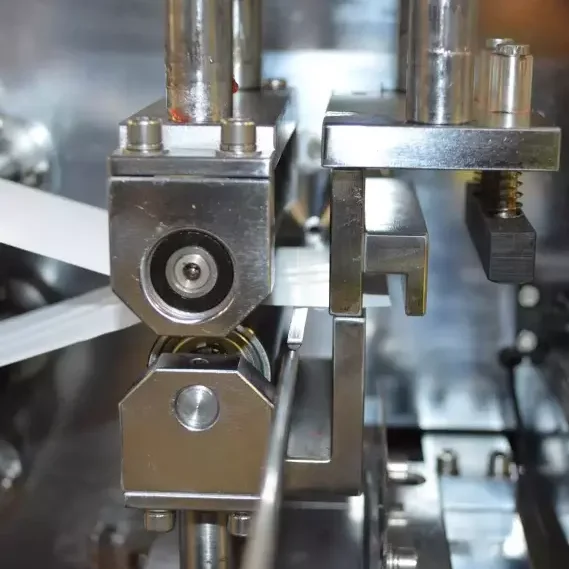

Product Images

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.