* Can achieve continuous, intermittent coating;

*Slot extrusion coating method, high coating precision and good coating consistency;

* Substrate tension control, stable belt, configuration of correcting device;

* Hot air oven, double-sided airing on the top and bottom, good drying effect;

*PLC control, touch screen operation, easy to use;

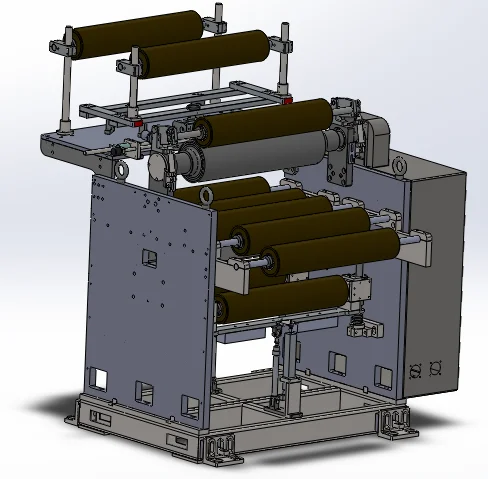

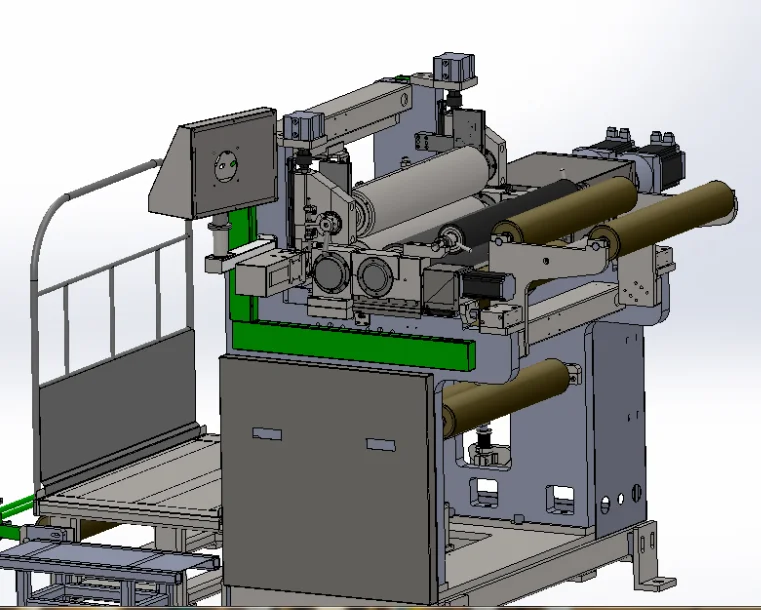

Machine structure

1. Integral unwinding, coating head mechanism

2. Pumping system

3. Drying system

4. Winding mechanism

5. Control system

Technical parameters

|

1. Base material basic parameters |

||

|

Material type |

Cathode substrate |

Anode substrate |

|

copper foil |

aluminum foil |

|

|

Thickness |

(8-30) μm |

(10-30) μm |

|

Width of substrate |

(200-320) mm |

(200-320) mm |

|

2. Coating parameters |

||

|

Material |

cathode film |

Anode film |

|

Graphite, mesophase carbon, hard carbon, etc |

Lithium cobalt acid, nickel cobalt manganese lithium, lithium manganese acid, lithium ferrous phosphate |

|

|

Dry coating thickness |

(50-150) μm (excluding single dry foil) |

(50-150) μm (excluding single dry foil) |

|

Wet coating thickness: |

100μm~300μm |

100μm~300μm |

|

solid content |

(40-70) ±5% |

(30-80) ±5% |

|

specific gravity |

(1.0-1.4) g/cm3 |

(1.0-2.5) g/cm3 |

|

viscosity |

(2500-8000) CPS |

(1000-10000) CPS |

|

temperature |

Control by process RT~140℃,adopt electric heating method |

|

|

solvent |

NMP Oil system/drainage system |

NMP Oil system/drainage system |

|

3. Basic machine parameters |

||

|

Width of coating roller |

400mm |

|

|

Effective coating width |

300mm and below |

|

|

Coating method |

Continuous extrusion coating (including strip coating) / intermittent extrusion coating |

|

|

Coating speed |

1~5m/min (Related to oven temperature, film state and coating process Settings); |

|

|

Power supply |

380 V x 50 Hz, three phase(ontrol power supply 220 V x 50 Hz, single phase) |

|

|

Total power |

Max. 50KW |

|

|

air source |

0.6 MPa |

|

|

Total machine length: not more than 10 meters |

||

Product Images

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.