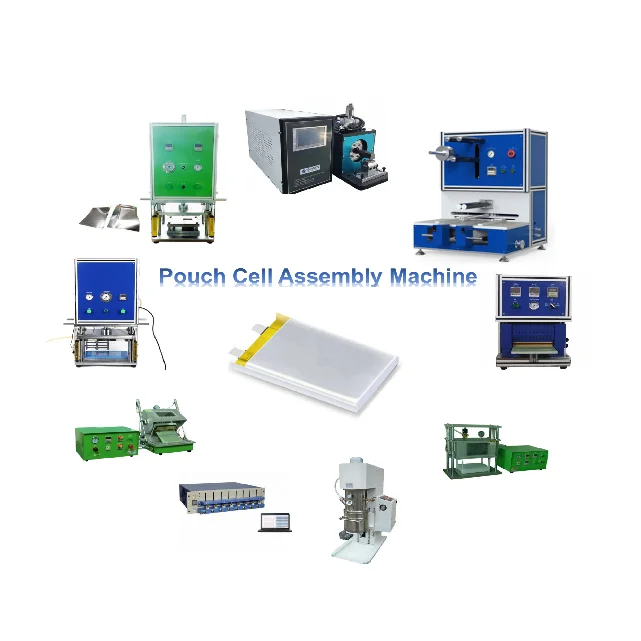

Lab Pouch Cell Assembly Line Pilot Pouch Cell Production Line Equipment

Pouch Cell Lab Line

In 1995, Li-polymer surprised the battery world with a radical new design, the pouch cell. Rather than using a metallic cylinder and glass-to-metal electrical feed-through for insulation, conductive foil tabs welded to the electrode and sealed to the pouch carry the positive and negative terminals to the outside.

More and more research institutes and universities tend to establish a new lab for pouch cell research.TMAX provides one total solution for the pouch cell fabrication, from research equipment to prototype production line and from low-cost device to high-end automatic machines, based on our more than20 years experience.

Specifications

|

Process |

Item |

Product Name |

Description |

|

Powder processing |

Furnace |

Please refer to attached furnace quotation |

|

|

Slurry vacuum mixing |

Mixer |

Compact Vacuum Mixer With Vibration Stage & Two Containers (150 & 500ml) |

With 150ml and 500ml container, Rotary Speed:320rpm |

|

Compact Dual-Shaft Planetary Vacuum Mixer Machine With A 500 ML Container |

Dual-Shaft, 500ml container, Rotary Speed:600rpm |

||

|

Electrode coating |

Coater |

Laboratory Electric Heat Film Coating Machine For Electrode Coater With Dryer |

Effective coating area:100*250mm |

|

200*300mm |

|||

|

250*550mm |

|||

|

250*800mm |

|||

|

Micrometer Adjustable Film Applicator With Digital Display-100mm Width |

With digital gauge,coating width:100mm |

||

|

Lab Compact Film Vacuum Coating Machine with 300mm Width Doctor Blade |

Bar coating, coating width:100mm |

||

|

Electrode pressing |

Press Machine |

Electric Roller Press Machine With Variable Speed |

100*100(dia*width,mm),electric,with heating function |

|

100*200 |

|||

|

100*300 |

|||

|

100*400 |

|||

|

Lab Small Pressing Calendar Rolling Machine |

100*100(dia*width,mm),maual,without heating function |

||

|

100*200 |

|||

|

100*300 |

|||

|

Electrode cutting |

Die cutter |

Lab Electrode Die Cutter For Pouch Cell Electrodes Cutting |

Suitable for small size electrode cutting |

|

Lab Electrode Die Cutter For Pouch Cell Electrode Sheet With Two Size Range Optional |

Suitable for various size range electrode cutting |

||

|

Electrode stacking |

Stacker |

Laboratory Electrode Stacking Machine For Pouch Cell Production Line |

Suitable for various electrode size stacking, manual |

|

Semi-Automatic Stacking Machine For Pouch Cell Electrodes |

Max suitable electrode size:200mm*200mm |

||

|

Tab Welding |

Ultrasonic spot welder |

Al Tab Ni Tag Ultrasonic Welding Machine |

2000W, 40kHz, max.40 Layers |

|

3000W, 40kHz, max.60 Layers |

|||

|

Case forming |

Forming machine |

Pouch Cell Case/Cup Forming Machine for Aluminum-Laminated Films |

Including one customized forming die |

|

Including one customized forming die |

|||

|

Top&side welding |

Hot sealing machine |

Compact Heating Sealer For Sealing Laminated Aluminum Case Of Pouch Cells |

With rubber sealing blade, suitable for sealing with tab, sealing length:200mm |

|

Sealing length:300mm |

|||

|

Electrolyte injection |

Electrolyte filing machine |

Bottletop Electrolyte Digital Dispenser With 32oz Boston Round Glass Bottle: 1- 10 Ml Adjustable |

Manual operation, digital display |

|

Single Head Electric Injection Pump For Lithium Ion Battery Electrolyte Filling |

Automatic, PLC controlled |

||

|

Electrolyte Diffusion & Degassing |

Diffusion & Degassing Chamber |

Pouch Cell Electrolyte Diffusion/Degassing Chamber |

Can be put into glove box;Operation Temperature:-20 to 40 ℃ |

|

Vacuum sealing |

Vacuum sealer |

Laboratory Vacuum Sealing Machine |

Can be put into glove box, sealing length:200mm |

|

Sealing length:300mm |

|||

|

Sealing length:400mm |

|||

|

Battery performance testing |

Battery tester |

5V6A 8 Channel Lithium Ion Battery Tester Equipment For Experiment |

Testing range from 12.0 mA to 6000 mA, up to 5V. |

|

10V10A 8 Channel Lithium Ion Battery Tester Equipment For Experiment |

Testing range from 12.0 mA to 10000 mA, up to 10V. |

||

Product Images

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.