We will ship all your order within 3 working days after receiving your payment. Otherwise, we will state in the invoice in advance.DXL/FedEX/TNT/UPS/EMS/China Post/Hong-kong Post are available.Please make sure your delivery address and contact telephone number are correct when you bid the item.

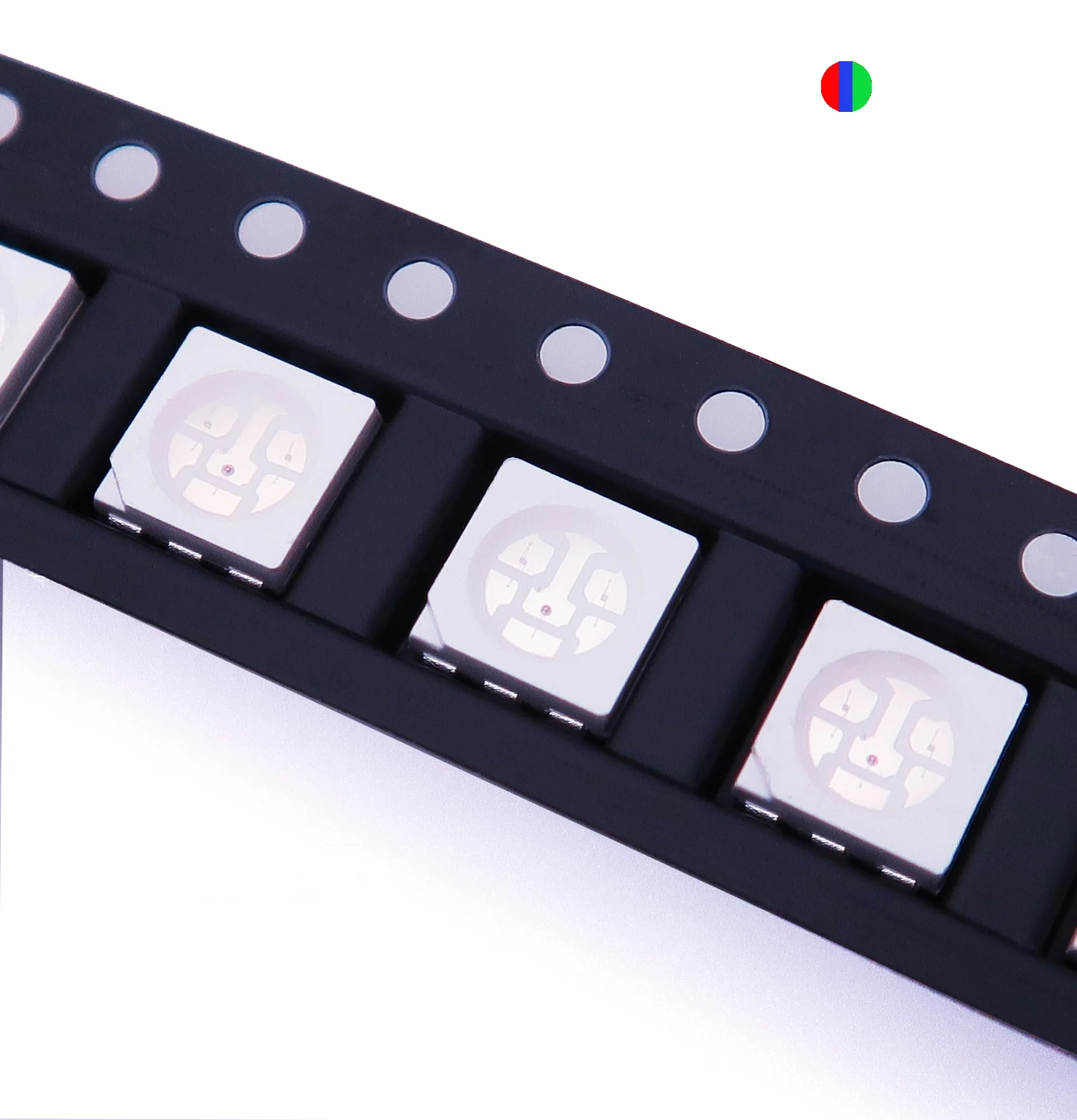

3.0-3.2V 0.06W 3-7 Lm Low Power Consumption Super Light Red Blue Green Light Led Diode Smd 3528 Led Chip SMD LED 3528

Integrity card

You may also like

Product Description

Power | 0.06(W) |

Forward Voltage | 1.8-3.2(V) |

Rated Current | 20m(A) |

The Brand OF Glue | Whalley |

Irritation Angle | 120(°) |

Thermal Resistance | ≤5(°/W) |

Pass The LM-80 Test | No |

Backward Voltage | 5(V) |

Chip Brand | Saman |

Wire Material | Silver Thread |

Luminous Efficiency | 100(lm/W) |

TJMAX | -30~+85(°) |

Color Temperature Range | 620-625(K) |

Electrostatic Breakdown Voltage (ESD) | 1000(V) |

Steady OF Deskop | EMC |

Color Tolerance | 〈7(SDCM) |

1000 Hours Conventional Aging | 100(%) |

Correlated Colour Temperature | 3528 Red light 1.9T thick 2K,3528 yellow light 1.9t thick 2K,3528 Blue light 1.9t thick 2K,3528 green Light 1.9t thick 2K (K) |

1、Features

Package ( L/W/H ) : 5.0*5.0*1.5mm

* Color : Ultra BrightStandard Yellow

* Lens: Yellow DiffuseFlat Mold

* EIA STD Package

* Meet ROHS, Green Product

* Compatible With SMT Automatic Equipment

Compatible With Infrared Reflow Solder And Wave Solder Process

* Color : Ultra BrightStandard Yellow

* Lens: Yellow DiffuseFlat Mold

* EIA STD Package

* Meet ROHS, Green Product

* Compatible With SMT Automatic Equipment

Compatible With Infrared Reflow Solder And Wave Solder Process

2、 Package Profile & Soldering PAD Suggested

3. Absolute Maximum Ratings At Ta=25℃ |

Parameter | Symbol | Rating | Unit | |||

Power Dissipation | Pd | Y1 | 90 | mW | ||

Y2 | 90 | |||||

Y3 | 90 | |||||

Peak Forward Current (1/10 Duty Cycle, 0.1ms Pulse Width) | IFP | Y1 | 100 | mA | ||

Y2 | 100 | |||||

Y3 | 100 | |||||

DC Forward Current | IF | Y1 | 30 | mA | ||

Y2 | 30 | |||||

Y3 | 30 | |||||

Reverse Voltage | VR | Y1 | 5 | V | ||

Y2 | 5 | |||||

Y3 | 5 | |||||

Operating Temperature Range | Topr | -30°C ~ + 85°C | ||||

Storage Temperature Range | Tstg | -40°C ~ + 90°C | ||||

Soldering Condition | Tsol | Reflow soldering : 260°C For 5 Seconds Hand soldering: 300°C For 3 Seconds | ||||

4、 Electrical Optical Characteristics At Ta=25℃ |

Parameter | Symbol | Color | Min. | Typ. | Max. | Unit | Test Condition |

Luminous Intensity | IV | --- | --- | --- | Mcd | IF = 60mA | |

Y | 600 | ---- | 800 | ||||

--- | --- | --- | |||||

CIE 1931 Coordinate | Nm | Y | --- | 588 | --- | nm | IF=20mA/dice |

Y | --- | 590 | --- | ||||

Y | --- | 592 | --- | ||||

Forward Voltage | VF | Y | --- | 2.0 | --- | V | IF=20mA /dice |

Y | --- | 2.2 | --- | ||||

Y | --- | 2.4 | --- | ||||

Reverse Current | IR | Y | --- | --- | 10 | uA | VR=5V |

Y | --- | --- | 10 | ||||

Y | --- | --- | 10 | ||||

Viewing Angle | 2θ1/2 | --- | --- | 120 | --- | deg | IF = 20mA/dice |

Notes: 1. Luminous intensity is measured with a light sensor and filter combination that approximates the CIE eye-response curve. 2. θ1/2 is the off-axis angle at which the luminous intensity is half the axial luminous intensity. 3. The dominant wavelength, λd is derived from the CIE chromaticity diagram and represents the single wavelength which defines the color of the device. |

5、Label explanation CAT:Luminous Intensity Rank(unit : mcd)HUE:CIE 1931 Coordinate Rank REF:Forward Voltage Rank(unit : V) Rank Tolerance: a. Luminous Intensity: ± 15% b. HUE: ± 0.01 c. Forward Voltage: ± 0.1V |

Classification | Test Item | Test Condition | Reference Standard | Reference Standard |

Endurance Test | Operation Life | Ta= Under Room Temperature As Per Data Sheet Maximum Rating | 1000HRS (-24HRS,+72HRS)*@20mA | MIL-STD-750D:1026 MIL-STD-883D:1005 JIS C 7021:B-1 |

High Temperature, High Humidity Storage | IR-Reflow In-Board, 2 Times Ta= 65±5℃,RH= 90~95% | 240HRS±2HRS | MIL-STD-202F:103B JIS C 7021:B-11 | |

High Temperature Storage | Ta= 105±5℃ | 1000HRS (-24HRS,+72HRS) | MIL-STD-883D:1008 JIS C 7021:B-10 | |

Low Temperature Storage | Ta= -55±5℃ | 1000HRS (-24HRS,+72H RS) | JIS C 7021:B-12 | |

Environmental Test | Temperature Cycling | 105℃ ~ 25℃ ~ -55℃ ~ 25℃ 30mins 5mins 30mins 5mins | 10 Cycles | MIL-STD-202F:107D MIL-STD-750D:1051 MIL-STD-883D:1010 JIS C 7021:A-4 |

Thermal Shock | IR-Reflow In-Board, 2 Times 85 ± 5℃ ~ -40℃ ± 5℃ 10mins 10mins | 10 Cycles | MIL-STD-202F:107D MIL-STD-750D:1051 MIL-STD-883D:1011 | |

Solder Resistance | T.sol= 260 ± 5℃ | 10 ± 1secs | MIL-STD-202F:210A MIL-STD-750D:2031 JIS C 7021:A-1 | |

IR-Reflow Normal Process | Ramp-up rate(183℃ to Peak) +3℃/ second max Temp. maintain at 125(±25)℃ 120 seconds max Temp. maintain above 183℃ 60-150 seconds Peak temperature range 235℃+5/-0℃ Time within 5°C of actual Peak Temperature (tp) 10-30 seconds Ramp-down rate +6℃/second max | -------- | MIL-STD-750D:2031.2 J-STD-020C | |

IR-Reflow Pb Free Process | Ramp-up rate(217℃ to Peak) +3℃/ second max Temp. maintain at 175(±25)℃ 180 seconds max Temp. maintain above 217℃ 60-150 seconds Peak temperature range 260℃+0/-5℃ Time within 5°C of actual Peak Temperature (tp) 20-40 seconds Ramp-down rate +6℃/second max | -------- | MIL-STD-750D:2031.2 J-STD-020C | |

Solderability | T.sol= 235 ± 5℃ Immersion rate 25±2.5 mm/sec Coverage ≧95% of the dipped surface | Immersion time 2±0.5 sec | MIL-STD-202F:208D MIL-STD-750D:2026 MIL-STD-883D:2003 IEC 68 Part 2-20 JIS C 7021:A-2 |

7、Cautions Application 1. A LED is a current-operated device. The slight shift of voltage will cause big change of current, which will damage LEDs. Customer should use resistors in series for the Over-Current-Proof. 2. In order to ensure intensity uniformity on multiple LEDs connected in parallel in an application, it is recommended to use individual resistor separately, as shown in Circuit A below. The brightness of each LED shown in Circuit B might appear difference due to the differences in the I-V characteristics of those LEDs. 3. High temperature may reduce LEDs’ intensity and other performances, so keeping it away from heat source to get good performance is necessary. |

Storage 1.Before opening original package, it is recommended to store them in the following environment: Temperature: 5℃~30℃ Humidity: 85%RH max. 2. After opening original package, the storage ambient for the LEDs should be in 5~30°C temperature and 60% or less relative humidity. 3. In order to avoid moisture absorption, it is recommended that the LEDs that out of the original package should be stored in a sealed container with appropriate desiccant, or in desiccators with nitrogen ambient. 4. The LEDs should be used within 168hrs (7 days) after opening the package. Once been mounted, soldering should be quick. 5. If the moisture absorbent material (silica gel) has faded away or the LEDs stored out of original package for more than 168hrs (7 days), baking treatment should be performed using the conditions: 60℃ at least 24 hours. |

ESD (Electrostatic Discharge )-Protection A LED (especially the Blue、White and Green product) is an ESD sensitive component, and static electricity or power surge will damage the LED. ESD-damaged LEDs will exhibit abnormal characteristics such as high reverse leakage current, low forward voltage, or “no light-up” at low currents, etc. Some advice as below should be noticed: 1. A conductive wrist strap or anti-electrostatic glove should be worn when handling these LEDs. 2. All devices, equipment, machinery, work tables and storage racks, etc. must be properly grounded. 3. Use anti-static package or boxes to carry and storage LEDs. And ordinary plastic package or boxes is forbidden to use. 4. Use ionizer to neutralize the static charge during handling or operating. 5. All surfaces and objects within 1 ft close to LEDs measure less than 100V. |

Cleaning Use alcohol-based cleaning solvents such as IPA (isopropyl alcohol) to clean LEDs if necessary. Soldering 1. Soldering condition refer to the draft “Soldering Profile Suggested” on page 1. 2. Reflow soldering should not be done more than 2 times. 3. Manual soldering is only suggested on repair and rework. The maximum soldering temperature should not exceed 300°C within 3 |

Company Introduction

Shenzhen Tianqi Sheng Electronic Co., Ltd. Established in 2000 as independent distributor of electronic components, specializes in offering all kinds of world famous brands on Active and Passive components, besides, we are also strong on the Capacitors like multilayer chip ceramic capacitor, aluminum capacitor, tantalum capacitor and electrolytic capacitor, the components are widely used in electrical home appliances, communications, industry, and military etc. We can provide one stop BOM service.

Credit Report

Our Services & Strength

We can provide one stop BOM service, also can help you find halt production part no.

Packing&Shipping

Our logistics.

FAQ

Q: Are your products original?

A: Yes! All products are original and produced by original manufacturers. Our parts could accept any kinds of testing, if there is quality problems we will take responsible.

Q: What is your warranty?

A: Within 90 days after package have been received.

Q: What is your lead time?

A: There are on lead time for in-stock products. Most of the parts could be shipped out within 3 days after payment have been confirmed.

Q: What’s the MOQ for your products?

A: We accept small orders from our customers. Please feel free to contact us.

Q: May I have a sample for testing?

A: Yes! Only to pay shipping cost, free samples could be sent for testing.

Q: How do I pay for the order?

A: You may pay by TT, Paypal, Western Union and Ali-baba online.Or you may also consult us.

Q: How are my parcel is shipped?

A: Normally we use DHL, FedEx, TNT, EMS etc. Please contact with us otherwise.

Q: Do you provide the BOM Kitting service? Can I send my BOM to you?

A: Yes, certainly. Please feel free to contact us and send us the BOM, we will quote to you.

A: Yes! All products are original and produced by original manufacturers. Our parts could accept any kinds of testing, if there is quality problems we will take responsible.

Q: What is your warranty?

A: Within 90 days after package have been received.

Q: What is your lead time?

A: There are on lead time for in-stock products. Most of the parts could be shipped out within 3 days after payment have been confirmed.

Q: What’s the MOQ for your products?

A: We accept small orders from our customers. Please feel free to contact us.

Q: May I have a sample for testing?

A: Yes! Only to pay shipping cost, free samples could be sent for testing.

Q: How do I pay for the order?

A: You may pay by TT, Paypal, Western Union and Ali-baba online.Or you may also consult us.

Q: How are my parcel is shipped?

A: Normally we use DHL, FedEx, TNT, EMS etc. Please contact with us otherwise.

Q: Do you provide the BOM Kitting service? Can I send my BOM to you?

A: Yes, certainly. Please feel free to contact us and send us the BOM, we will quote to you.

Why Choose Us

Related Products