smooth surface to make sure the core's property, such as Current Loss, Exciting Voltage

CRGO & CRNGO Standard and Customized

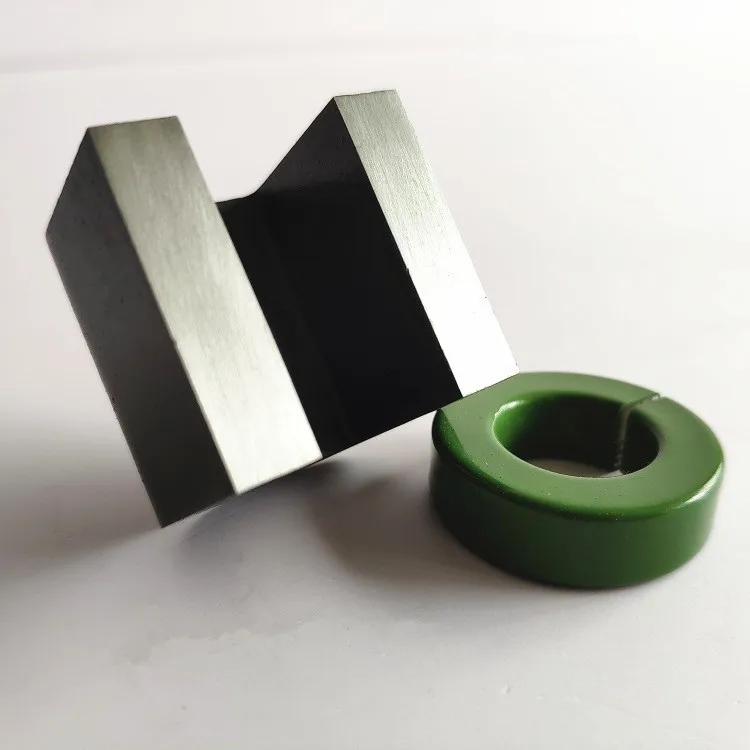

Silicon Steel Tape Wound Cores for Electrical Equipment

Detailed Images

Cutting

Surface

Winding

Planeness

not only influence the exterior, but also explain the high precision of winding equipment

Uniformity

Size

the consistency of external total height and width is beneficial to assembly

Welding | Spot welding is firm and smooth, and does not weld through two layers |

Winding | winding is tight, the start and end of the sheet can not be turned up |

Planeness | surface unevenness is less than 0.1mm |

Fineness | No crystalline fine particles (no crystalline fine particles on the cut surface) |

Cut face | No obvious crack on the cutting face (no light transmission and peeling between layers) |

Surface | Visually without burrs, rust, or deformation (to control deformation within tolerances) |

Products | Do not contain Pb\Cd\Hg\Cr\PBBs\PBDEs |

Technic

CRGO Tape wound Cores

wind one long continuous silicon steel tape tightly into a spiral

advantage: no air gap, high magnetic properties, easy to roll

weakness: difficult to wind large cores and realize mechanized

Application

Recommend Products

Company Introduction

Certificate

RoHS

The purpose of this standard is to eliminate harmful substances in electrical and electronic product, such as Pb\Cd\Hg\Cr\PBBs\PBDEs.

As we know, there are harmful heavy metals in the process of producing electrical and electronic products.

Today, people all over the world are particularly concerned about environmental protection.

In order to adapt to this trend, what products Wuxi Weibang launched are all undertaken the RoHS standards, not only the materials used, but also the finished products.

Production Process

Packaging & Shipment & Payment