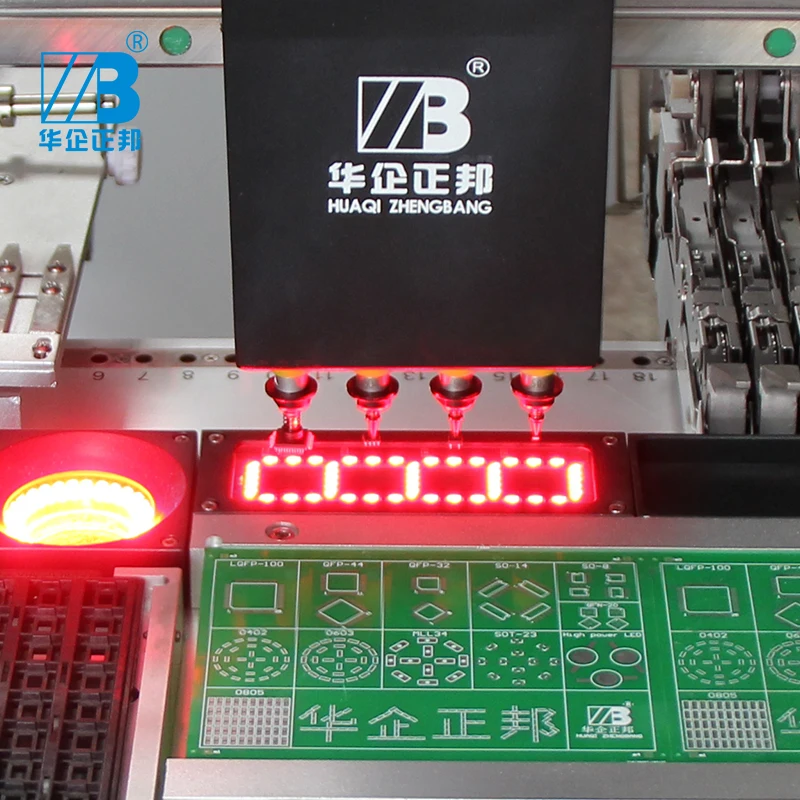

ZHENGBANG high precise 6 camera desktop smt pick and place machine ZB3545TP for PCB development

(1). Step servo motor.

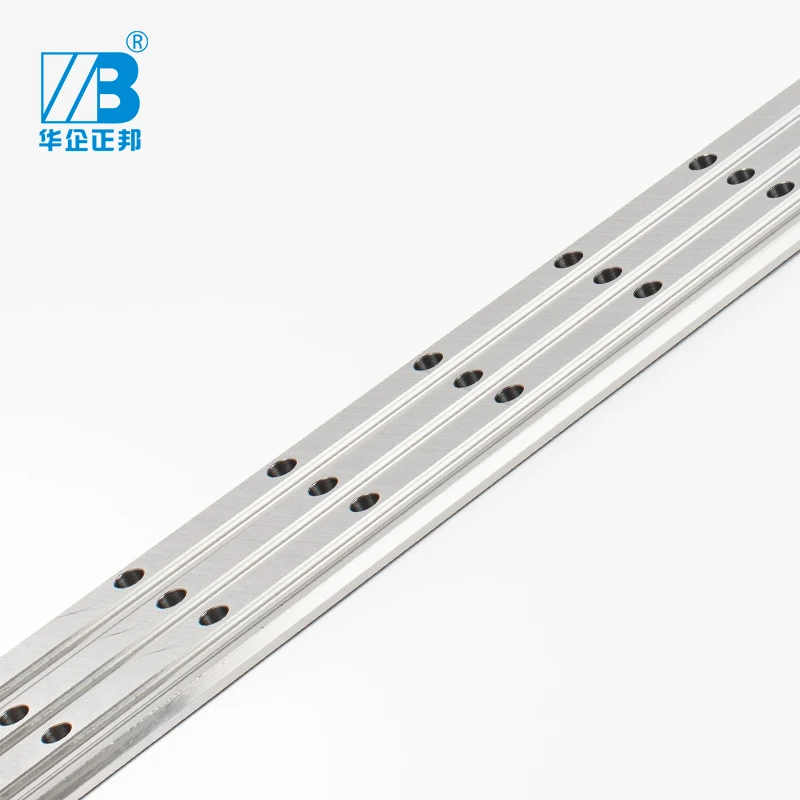

(2). Collocate Taiwan HIWIN linear guider

(4). Double Mark possess recognizing and positioning.

(5). High resolution ratio CCD Industrial camera +4 small camera for high precision recoginse.

(6). Intelligent P&P heads, Automatic dispose picking fail 360-degree orientation.

(7). Support arbitrary IC try, Convenience/Reasonable/Arbitraty set.

(8). The up and down looking vision system.(automatic identify mark/automatic identify the centre of components).

(9). The humanization control panel, care of every steps of your operation.

(10). Humanization PC Software, could support most of PCB design software software.

| System | Items | Content |

| Mounting System | Mounting heads | 4 PCS |

| Mounting accuracy | 0.025mm | |

| Mounting angle | 0~360° | |

| Theoretical Velocity | 7000pcs/hour | |

| Normal mounting | 6000pcs/hour | |

| Actual Visual Mounting | 5000pcs/hour | |

| Nozzle type | Juki nozzle | |

| Elements for mounting | RC (0402, 0603, 0805, 1206, etc) | |

| LED lamp (0603, 0805, 3014, 5050, etc) | ||

| Chip (SOT, SOP, QFN, BGA, etc) | ||

| Substrate | PCB minimal size | 10×10mm |

| PCB maximum size (no tray) | 350×450mm | |

| PCB thickness | ≤2mm | |

| PCB warp allowable value | <1mm | |

| Feeder | Type | Yamaha CL feeder |

| Specification | 8mm,12mm,16mm,24mm,32mm | |

| Quantity | 38pcs | |

| Tubular feeder | Maximum 4-3 or 3-5 tube feeder | |

| IC tray | postposition 1pc tray | |

| X, Y, Z axis | X, Y axis moving range | 630×540mm |

| Z axis moving range | 12mm | |

| Z axis rotation angle | 0~360° | |

| Visual System | Visual system | independent research and development |

| Visual camera | CCD high-definition camera | |

| Visual quantity | 6pcs (5 Parts camera, 1 PCB camera) | |

| Identification ability | MAX.22*22mm | |

| Control System | PC system | PC system |

| Operational software | independent research and development | |

| Compatible file format | CSV, TXT. format file | |

| Programming mode | Support online and offline | |

| Pressure | 0.8MPa | |

| Basic Parameter | Power | 500W |

| Power supply | AC220V±10% 50Hz | |

| Size | 1165×1105×630mm | |

| weight | 120kg |

Wenzhou Zhengbang Electronic Equipment Co., Ltd was Established 2006, located in Ouhai Zone,Wenzhou,China,which is a professional manufacturer specializing in research,development,production ,marketing and service of soldering machines.

We are the leader of soldering machines supplier, our main products are Solder Paste Mixer, Silk Screen Printing Machines, Pick And Place Machine, Reflow Oven, SMT Inspection Conveyor, Turnover Cart, Feeder, Nozzles, Heating Plate, Dip Soldering Machines, Soldering Pot, PCB cutting machine, and so on, Most our products have passed CE certification and lots of products got patent.

1. In case the machine breaks down, where can I find the spare parts?

Once your machine have the problem, please contact me or leave a message to my email. I will forward your message to our engineers and within 24 hours we will arrange inspection for your machine remotely.

If it needs replacing any spare parts, we will send it to you directly by TNT,DHL or others.

We have the technical teams in some area. If you need local service, you have to cover the travel expenses, labor cost. They will provide service for you directly.

The machine will be packed with some spare parts according to our experience.

2. Payment term?

We accept:T/T, VISA, PAYPAL, WEST UNION, BANK TRANSFER, ONLINE BANK PAYMENT

3. What about the lead time?

1~2 weeks after we received the payment, we will start the delivery. For customized order, it depends on practical situation.

4. How about the Training ?

We provide the online remote training service, and we will offer you the operating video and manual for users’ repeatedly learning.

5. What’s the applicative component size for this machine?

Minimum component size: 0402.

maximum size: lead pitch no more than 0.5mm, such as QFP100.

Components height:<5mm.

6.Which nozzle suit for the component?

Machine used YAHAMA series nozzle.

size 500 nozzle:1005,1608,2012.component minimum width:0.45mm to 1.45mm.

Size 501 nozzle:0603,0402.component minimum width :below 0.45mm

Size 502 nozzle:0805,1005,1608,2012.component minimum width:0.45mm to 0.75mm.

Size 503 nozzle:0805,1206,1608,2012.component minimum width:0.75mm to 1.45mm.

Size 504 nozzle:2012,3216,SOT23.component minimum width:1.1mm to 2.5mm.

Size 505 nozzle:component minimum width:2.5mm to 4mm.

Size 506 nozzle:component minimum width:4mm to 7mm.

JUKI smt pick and place machine, smt pick and place machine, pick and place, led mounter machine, led pick and place machine, smt chip mounter,mounter, smt mounter,chip mounter, JUKI shotter, JUKI second hand machine, led automatic production line machine, led making machine, led assembly machine, led light making machine, led light making machine, led bulb manufacturing machine, led bulb assembly machine, led street light assembly, led lamp assembly, led panel light assembly, charger making machine, laptop making machine, pcb assembly line, led tube light assembly machine, JX-300 LED mounter machine, led&smd product line, led&smd, semi auto production line, full-auto production line, automatic production smt line, auto smt line, smt automatic production line, LED LINE Production, LED bulb assembling Unit, Small LED bulb assembling Unit, LED pick and place machine , smd pick & place machine, auto led lighting assembly machines, SMT Assembly line for LED,total solution to Full led light assembling lines, assembly line machine to assemble the LED Bulb, SMT assembly line for small and medium batches, PCB fabrication, pick & place machine and Reflow Oven, pick and place for electronic components, led lights manufacturing machine, Led placement, Desktop smd pick and place machine, smt led assemble robot machine, Solar Panel Production Line, led street lights assembly line, led street lights production line, led production line,

SMT Pick and Place Machine for PCB SMT Production Line

SMT Pick and Place Machine for PCB SMT Production Line