Product Description

1.CE,ISO certification

2.Custom Design Acceptable

3.Higher Precision And Faster Speed

As a professional manufacturer,we can make High Precise Metal Stud and Track Cold Roll Forming Machine by customer`s demand, with a profile drawing and thickness, we can design the machine quickly.Until now,we can do many kinds of roof panel machine,such as trapezoidal sheet making machine, corrugated sheet making machine, glazed tile making machine, Double Layer Roll Forming Machine and so on.

1.CE,ISO certification

2.Custom Design Acceptable

3.Higher Precision And Faster Speed

As a professional manufacturer,we can make High Precise Metal Stud and Track Cold Roll Forming Machine by customer`s demand, with a profile drawing and thickness, we can design the machine quickly.Until now,we can do many kinds of roof panel machine,such as trapezoidal sheet making machine, corrugated sheet making machine, glazed tile making machine, Double Layer Roll Forming Machine and so on.

1 | Power requirement | Type | 380v/3ph/50hz | ||

Main Motor power | 7.5kw | ||||

Cutter power | 5.5kw | ||||

2 | Forming speed(m/min) | 20-25m/min max | Not include the time of cutting | ||

3 | Forming stations | 16stations | |||

4 | Material of rollers | CR12 | |||

5 | Thickness of structure | 30mm | |||

6 | Forming shaft diameter(mm) | 60 | |||

7 | GDrive | Gear box | |||

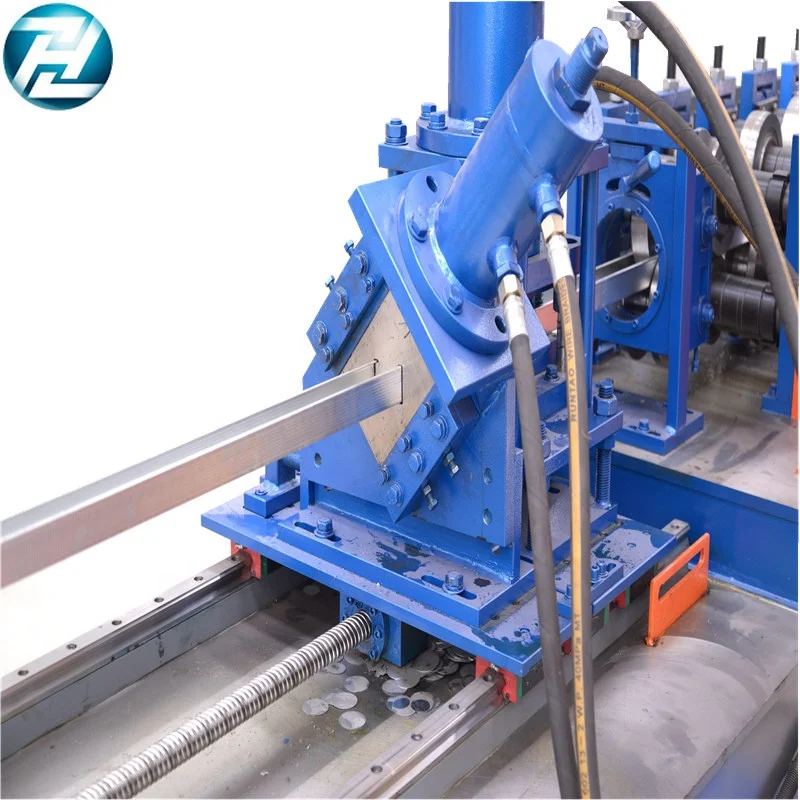

8 | Type of cutting | Hydraulic cutting | |||

9 | Control system | PLC xinjie | |||

10 | Install dimension(depend on the final design) | 4.8m×0.6m×1.2m | Without panel length | ||

11 | Total weight (Approx) | 3.3T | Depend on final design | ||

12 | Screen | Text screen /touch screen | |||

No | Name | Unit | Qty | |

*Max width 300mm *Inner diameter -460-510mm *Max loading capacity 1000kg *Manual operating type manual expansion to tighten the coil *Break down drive whole line stop while decoiler idle | ||||

2 | Feeding Table | set | 1 | |

3 | Forming Rollers | *Forming Station 16 nos *Forming Rollers material Cr12 *Forming Rollers hard treatment HRC 58-60 *Shaft of roller Diameter 40mm *Shaft material 40Cr,heat treatment, refine grinded *Machine frame: steel welding *Main sidewall thickness 25mm *Machine driven by universal joints via gearbox *Roll forming motor 5.5kw with frequency inverter controller *Gearbox RV worm gearbox | ||

set | 1 | *Hydraulic pump stand 1 set *Hydraulic Components taiwanese *Hydraulic System discharging protection with wind cooler *Edge cutting 2 sets both ends *Middle joint hole punching 23sets/152.4mm *Fire testing hole 2 sets both ends *Mould standard SKD-11 Steel Japanese *Mould frame&plate S45C *Mould pin SKH-9 steel Japanese *All mould treatment By slow-feeding Nc wire cutting | ||

set | *Driven machinical Auto Head *Operation Full automatic along with forming machine | |||

Electric Control system | set | *Frequency converter Silin ,Taiwanese *PLC Fatek ,Taiwanese *Touch screen weinview Taiwanese *Profile length cutting forming machine stops then cut *Operational controller: touch screen knob switch emg Brake down and so on (6)Power supplier 380V 50Hz 3phase |

FAQ

1. Q: What is the MOQ?

A: 1 set.

2. Q: What is the Delivery time?

A: Within 25 workdays.

3. Q: What is the Payment terms you can accept?

A: T/T or L/C.30% deposit,and before shipped we hope to receive the balance 70%.Also 100% L/C is accepted.

4. Q: What is the Warranty?

A: Within 12 mounts,all of the technical personnel are ready to serve you at any time.

Our Service

Pre-Sales Service

* Local market research and profile confirm .

* Sample testing support.

* View our Factory.

After-Sales Service

* Full assembled shipment , easy installation

* Free trainning .

* Engineers available to service machinery overseas.

Packing & Delivery

It will be loaded in one 20' container

Related Products

Recommend Products

Certifications