Firstly use software to build a model, and then split the 3D model to a layer-by-layer cross-section, ie, slicing, so as to guide the printer to print layer by layer.

The standard file format between design software and printers is the STL file. A STL file uses a triangular face to approximate the surface of a simulated object. The smaller the triangular face, the higher the generated surface resolution. PLY is a scanner that generates a 3D file by scanning, and the generated VRML or WRL file is often used as an input file for full-color printing.

It is a technique for constructing objects by layer-by-layer printing based on digital model files and using adhesive materials such as powder metal or plastic.

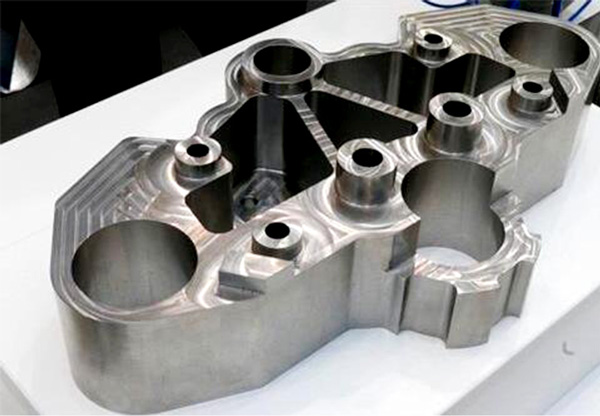

It is often used in the manufacture of molds in the fields of mold manufacturing and industrial design, and is gradually used for the direct manufacture of some products. There are already parts printed using this technology.

The technology is used in the jewelry:

Footwear, industrial design, construction, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms and other fields.

The 3D printing metal material

The raw materials for metal 3D printing are mainly Tool steel and martensitic steel, stainless steel (Austenitic stainless steel 316L, Martensitic stainless steel 15-5PH, Martensitic stainless steel 17-4PH) Pure titanium and titanium alloy, Inconel (Inconel 738、Hastelloy X、Inconel 625、Inconel 713、Inconel 718) Cobalt chromium alloy, bronze, Aluminum alloy....