Authors and their institutions:

Hung Cong Duong, Dan Chuai , Yun Chul Woo , Ho Kyong Shonc , Long Duc Nghiem, Vitor Sencadas

a Strategic Water Infrastructure Laboratory, School of Civil, Mining and Environmental Engineering, University of Wollongong, Wollongong, NSW 2522, Australia

b School of Mechanical, Materials and Mechatronics Engineering, University of Wollongong, Wollongong, NSW 2522, Australia

c Centre for Technology in Water and Wastewater, School of Civil and Environmental Engineering, University of Technology Sydney (UTS), P.O. Box 123, 15 Broadway, NSW 2007, Australia

d ARC Center of Excellence for Electromaterials Science, University of Wollongong, Wollongong, NSW 2522, Australia

Periodical:

Journal of Membrane Science

Impact Factor :

Article info:

Keywords: Membrane distillation (MD) Styrene-butadiene-styrene (SBS) Membrane fabrication Electrospinning Seawater desalination

Abstract:

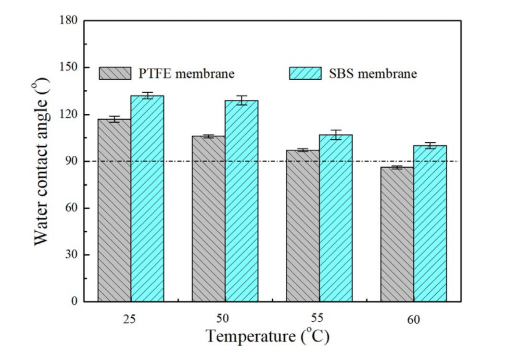

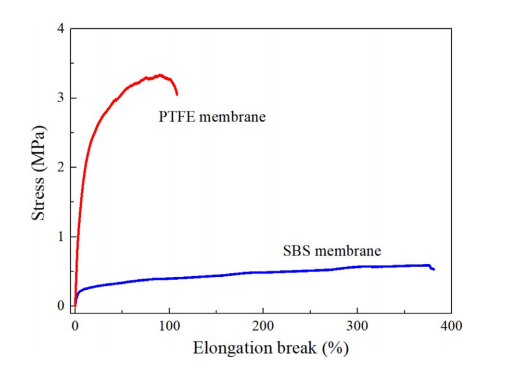

In this study, a novel hydrophobic, microporous membrane was fabricated from styrene-butadiene-styrene (SBS) polymer using electrospinning and evaluated for membrane distillation applications. Compared to a commercially available polytetrafluoroethylene (PTFE) membrane, the SBS membrane had larger membrane pore size and fiber diameter and comparable membrane porosity. The fabricated SBS showed slightly lower water flux than the PTFE membrane because it was two times thicker. However, the SBS membrane had better salt rejection and most importantly could be fabricated via a simple process. The SBS membrane was also more hydrophobic than the reference PTFE membrane. In particular, as temperature of the reference water liquid increased to 60 °C, the SBS membrane remained hydrophobic with a contact angle of 100° whereas the PTFE became hydrophilic with a contact angle of less than 90°. The hydrophobic membrane surface prevented the intrusion of liquid into the membrane pores, thus improving the salt rejection of the SBS membrane. In addition, the SBS membrane had superior mechanical strength over the PTFE membrane. Using the SBS membrane, stable water flux was achieved throughout an extended MD operation period of 120 h to produce excellent quality distillate (over 99.7% salt rejection) from seawater

Results and discussion:

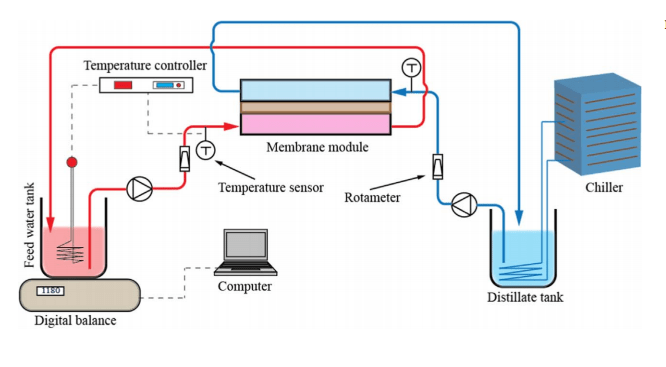

Fig. 1. The schematic diagram of the MD test unit

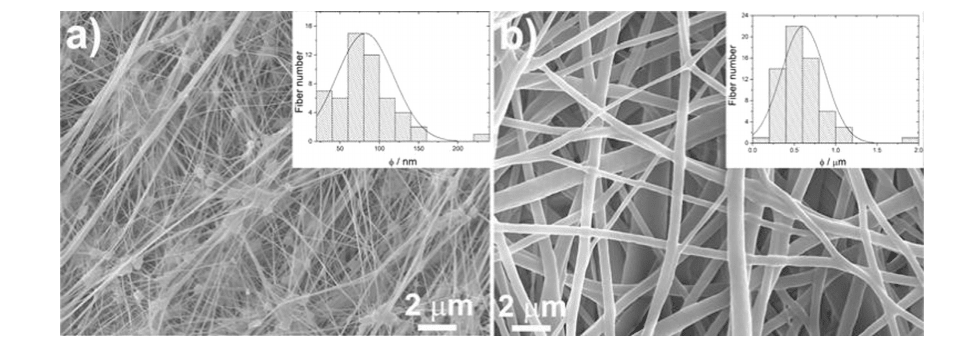

Fig. 2. Morphology of (a) the commercial PTFE membrane and (b) the fabricated SBS membrane. The insets present the fiber diameters distribution of the membrane samples.

Fig. 3. Water contact angle of the commercial PTFE and the fabricated SBS membranes at various temperatures. DI water was used as the reference liquid. Error bars represent standard deviations of 50 measurements.

Fig. 4. Stress-strain curves of the fabricated SBS and commercial PTFE membranes.

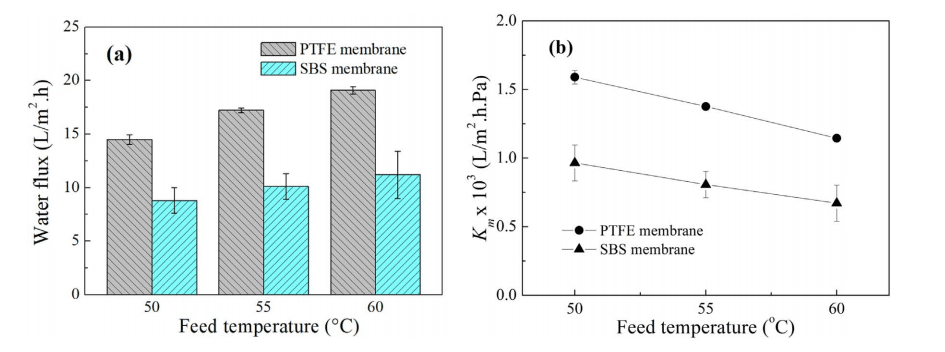

Fig. 5. (a) Water flux and (b) mass transfer coefficient (Km) as functions of operating feed temperature during the MD process using the PTFE membrane and the fabricated SBS membrane with the DI water feed. Operating conditions: feed and distillate circulation rates of 0.5 L/min (i.e. cross flow velocities of 0.06 m/s), distillate temperature of 20 °C. The error bars represent the standard deviation of five measurements.

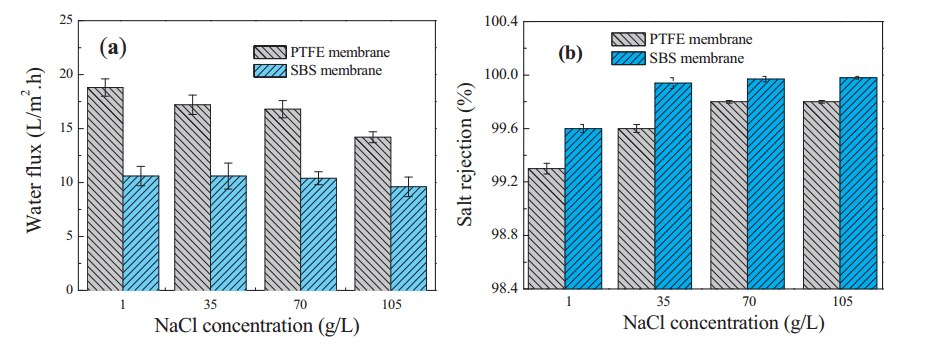

Fig. 6. (a) Water flux and (b) salt rejection of the fabricated SBS and PTFE membranes during the MD process with the synthetic NaCl solution feed at different feed salinity. Other operating conditions: feed temperature of 60 °C, distillate temperature of 20 °C, feed and distillate circulation rates of 0.5 L/min (i.e. cross flow velocities of 0.06 m/s). The error bars represent the standard deviation of five measurements.

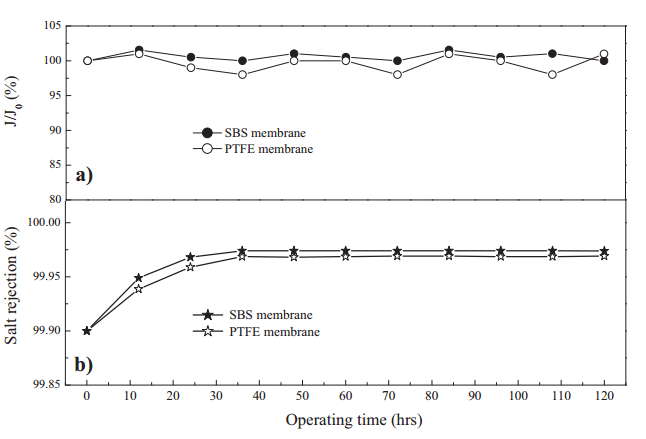

Fig. 7. (a) Normalised water flux (J/J0) and (b) salt rejection during the MD process of pre-filtered seawater feed. Operating conditions: feed temperature of 60 °C, distillate temperature of 20 °C, feed and distillate circulation rates of 0.5 L/min (i.e. cross flow velocities of 0.06 m/s). The salinity of the seawater feed was maintained constant by returning the distillate back to the feed tank throughout the experiments.

Conclusions:

A novel hydrophobic, microporous membrane based on styrenebutadiene-styrene (SBS) polymer was prepared using the electrospinning method. The SBS membrane was systematically evaluated in comparison to a commercial polytetrafluoroethylene (PTFE) membrane. The SBS membrane had larger membrane pore sizes and fiber diameters but comparable membrane porosity compared to the PTFE one. The fabricated SBS membrane was two times thicker, and thus had a lower water flux than the PTFE membrane. Nevertheless, the SBS membrane showed better salt rejection, higher surface hydrophobicity and superior mechanical strength over the reference PTFE membrane. The high membrane surface hydrophobicity prevented the intrusion of liquid into the membrane pores, thus improving the salt rejection of the SBS membrane. The SBS membrane showed stable water flux and excellent salt rejection (i.e. > 99.97%) throughout a long term MD operation using seawater as the feed. The results from this study reveal great potential of SBS as a promising alternative to conventional MD membrane materials for desalination applications.

Statement:

1. Literature download link: https://pan.baidu.com/s/1xblySRnyy-yJx3NrjaD20w

2. This article is only for academic exchanges, and is welcomed by the majority of scholars to share and reproduce. If there is any infringement of the article content, please contact us for modification.