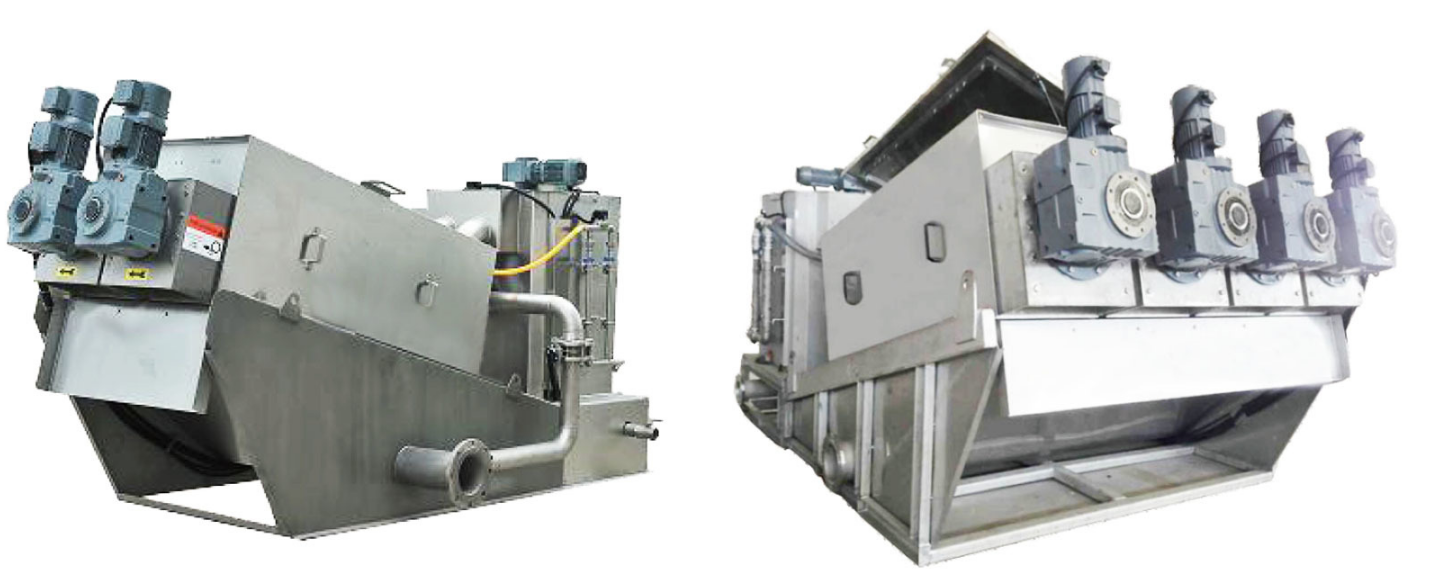

Clean water is becoming an increasingly valuable raw material, which is why the importance of municipal wastewater treatment continues to grow. In order to keep soil and water clean, the sludge from drinking water and wastewater treatment must be separated as efficiently as possible. For the dewatering and thickening of sewage sludge, sludge dewatering machine is now considered a good solution.

What Is Sludge Dewatering?

Sludge dewatering is a practice to reduce the volume of waste in preparation for effective disposal. Its purpose is to reliably and effectively concentrate waste into filter cakes with high solids content for convenient and economical treatment. Before the wastewater is released back to the environment, sludge is produced during wastewater treatment. For a long time, sludge is a challenge faced by the water treatment industry and is a by-product extracted from the mud during industrial or municipal wastewater treatment. Dewatering the sludge with a dewatering filter press can greatly reduce the weight and volume of the sludge before processing it. In fact, filter presses have excellent cake dryness, and in many cases, cake dryness is higher than other filter equipment.

Sludge dewatering separates sludge into liquid and solid components to minimize waste. There are various sludge dewatering technologies, including plate and frame and belt filter presses, centrifugal and geomembrane. In addition to these, there are other options available. It is important to note that dewatering is not about treating sludge or liquid, it can only separate solid and liquid components, so it is easier and more cost-effective to process the separated phase for final treatment. After the sludge is dehydrated, both solid and liquid components may contain contaminants and need to be treated separately.

What Are The Benefits of Sludge Dewatering Machine?

The sludge dewatering technique is widely used for water treatment machines. Let’s see how these machines benefit.

1. Cost Savings

Using a set of sludge dewatering machine in the water treatment process can make contribution to great cost savings. Sludge residues from water treatment can cost thousands of dollars per year in cities. Conventional wastewater treatment methods and wastewater treatment machine can generate large amounts of destructive substances in urban water plants. When these sludges get out of control, costs, and even taxes, will increase, which affects businesses and local residents. Many costs are attributable to related storage and transportation needs. It is crucial to use technical applications like dewatering to decrease those costs. Sludge dewatering helps cut back on disposal costs by decreasing the quantity of water-saturated soil. Additionally, it may save 75 to 80% of storage and transportation costs.

2. High Productivity

When a sludge dewatering machine is used to treat water and wastewater, productivity generally increases. Large and small cities have to provide non-toxic and clean water for enterprises, so enterprises can continue to operate without interference. For example, textile companies that dye fabrics require large amounts of clean water to produce brightly colored products such as jeans and pillows. The residue out of the production can operate off to make sludge, which may destroy the bases of buildings. If these sludges cannot be treated effectively, the site may be closed, completely stopping productivity. However, the use of sludge dewatering can prevent these problems.

3. Environmentally Friendly

The sludge dewatering machine is energy-efficient and eco-friendly. There are various kinds of water treatment machines which offer effectiveness and flexibility in water treatment. But many of them lack sustainability. Large water plants and industrial companies sometimes use treatment methods that consume large amounts of water. In addition, the disposal of waste requires heavy machinery, large amounts of energy, and transportation methods, which often rely on gases that cause carbon emissions. The application of dewatering technologies using organic chemicals (such as flocculants) can reduce these environmentally harmful practices, thereby making sludge dewatering a sustainable technical application.

4.Enhanced Performance

Compared to conventional methods, employing a sludge dewatering machine to take care of sludge residues from biological or mineral bodies can significantly improve the performance of the disposal process. Sludge dewatering provides the flexibility to treat all types of sludge, including thick or oily sludge. In addition, performance is improved since it needs no storage of sludge or thickener.

5. Applicable to A Wide Range

The sludge dewatering machine can be used to separate sludge from industries such as municipal sewage, food, beverage, chemical, leather, welding consumables, papermaking, printing and dyeing, and pharmaceuticals. This machine is suitable for dewatering sludge with high and low concentration. For the dewatering of low-concentration sludge, there is no need to build thickening ponds and storage ponds, which reduces construction costs, reduces phosphorus release and anaerobic odor.

All in all, when the final treatment of wastewater and water is required, sludge dewatering is the best technical application to use and the sludge dewatering machine is the best helper. When using this effective method, industrial and municipal water treatment plants will experience better performance, higher productivity and lower costs.