Aluminium surface ash removal and spraying are introduced

After alkali etching, ash removal is an essential process.

Ash is attached to the aluminum surface after the removal of alkali etching drab gray, sometimes also called out light or neutralization in the process of alkaline etching, aluminum contained intermetallic compounds or free silicon particle and other residues, almost not usually participate in the alkali erosion reaction, reaction product is not soluble in alkali etching bath, still remain on aluminum surface, forming a beige layer of loose surface layer of grey synthesis, usually adopt chemical method to remove the dissolved.

Most bath aluminum nitrate as ash, because of nitric acid has a strong oxidizing, dissolve performance is strong, can remove residues on the aluminum surface after alkali etching formed by various kinds of intermetallic compound particles of ash, more important is the strong oxidizing nitrate, nitric acid to the surface of aluminum surface clean bright even passivation, it consists of the oxide film of a very thin layer of protection.

In addition, the aluminum surface from alkaline activation state to acid passivation state, prevent the aluminum surface to produce snowflake corrosion.

Aluminum profile production must use spraying equipment, according to the surface treatment is divided into: anodized aluminum, electrophoretic coating aluminum, powder spraying equipment spraying aluminum, wood grain transfer aluminum, fluorocarbon spraying aluminum, polished aluminum.

There are generally common spray line spraying aluminum and fluorocarbon spraying aluminum.

Powder electrostatic spraying profiles are characterized by excellent corrosion resistance, acid, alkali and salt spray resistance is much better than oxidation coloring profiles.

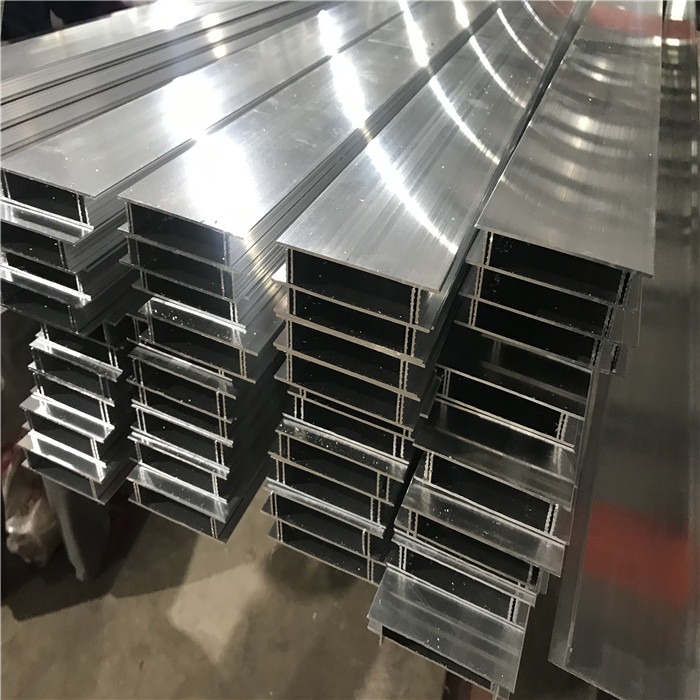

Aluminum alloy building profile products have high strength, light weight, corrosion resistance, good decoration, long service life, rich color and other advantages.

Generally, the surface of a good product will not lose light and color for 20 years.

So a good aluminum, a variety of process is indispensable.