Aluminum shell profile extrusion point

Aluminum profile shell in the bending process will inevitably scrap, which is very regrettable, so how to avoid and prevent this situation?

Next, we consult the technical staff to give you a brief introduction

Measure 1: Extrusion straightening

Aligning is a very important link in the manufacturing process of aluminum profile housing.

The straightening machine must pay attention to the strength used for straightening.

If the force is too large, it may cause deformation of aluminum profile, neck shrinkage, orange peel and other problems;

If the force is too low, it may not straighten, leading to bending.

So we have to control the intensity.

Step 2: Squeeze the box

This is also important.

After a fixed length has been sawed, the aluminum profiles will be framed.

At this time, the framers should pay attention to whether the material is large or small, whether the material is with pipes or drawn with flat die.

Generally speaking, it is not easy to bend when the two ends of the hanging frame with pipe materials are hung, but it is easy to bend when the two ends of the flat die are hung with small materials.

At this point, it should be lifted from both ends to the middle and framed.

But some aluminum profiles, even if this is not enough, such as shutters, shutters, gland, etc., must also be placed on aging aluminum profiles, and then suspended into the frame.

Measure 3: Surface treatment

After aging treatment, the hardness of the blank reaches the standard, so the aluminum profile is not easy to bend.

However, when placed on the shelf, attention should be paid to the two ends of the lifting material, as far as possible to avoid up and down drastic fluctuations, which will also cause a certain bending of the aging aluminum shell.

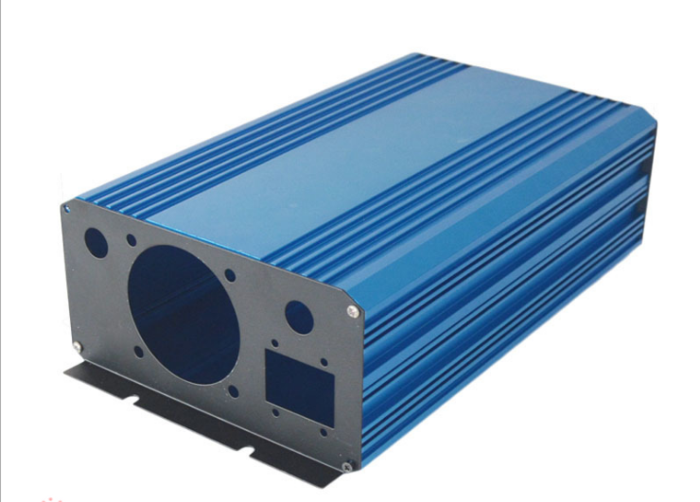

The aluminium profile shell is processed on the aluminium profile drawn.

It is highly flexible and can be cut at any depth.

Typically, there are circuit board slots in it.

Just plug it directly into the circuit board and you don't have to fix it.

Compared with other types of shell with unparalleled convenience, has a broader prospect of application.