CNC lathe machining is a small part of the CNC machining, CNC lathe processing there are two main processing forms:

The first is to fix the turning tool, processing unformed workpiece in rotation,

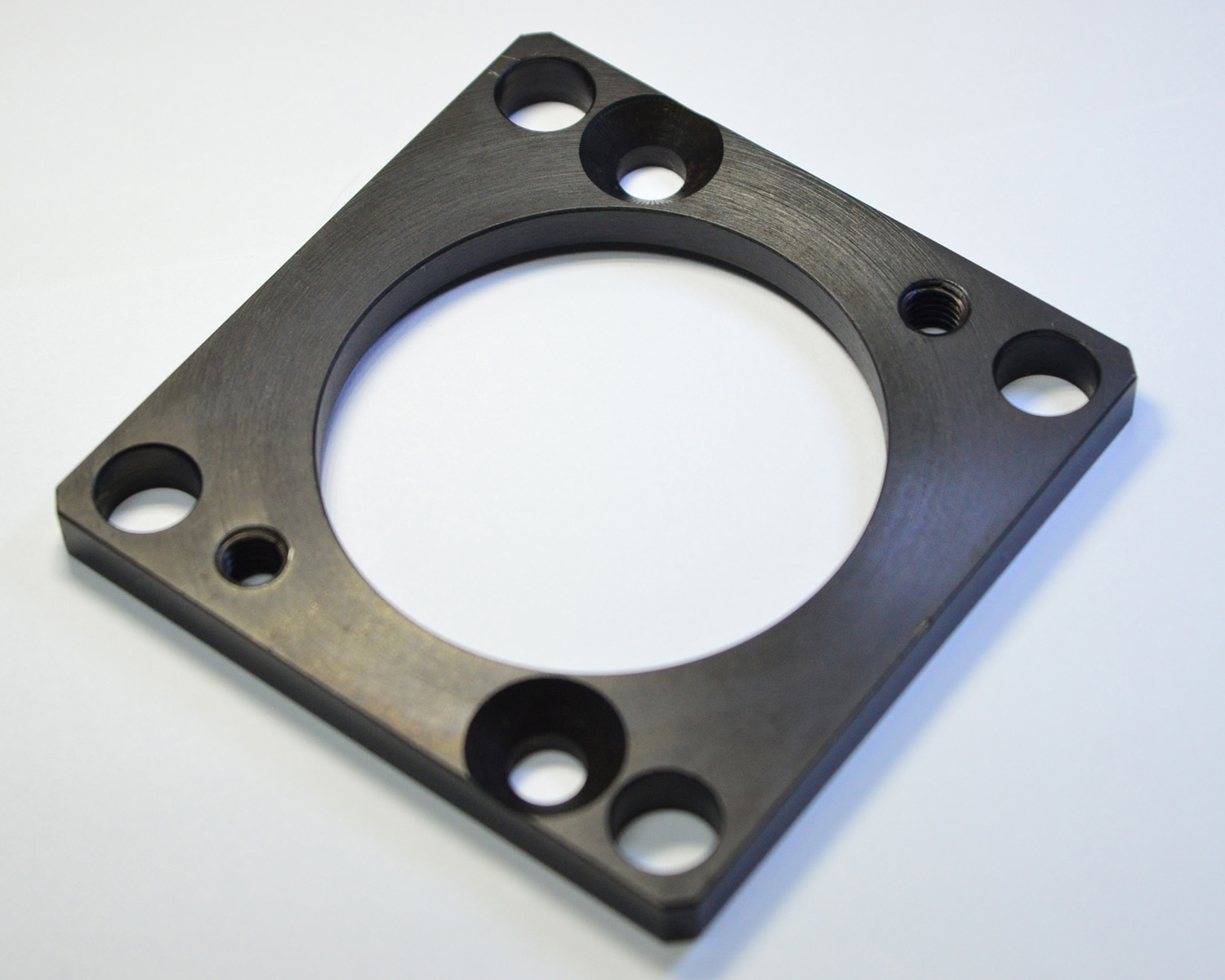

The second is the workpiece is fixed, high-speed rotation of the workpiece, lathe horizontal and vertical movement of precision machining. In the lathe can also be used bit, reamer, reamer, tap, dice and knurled tools for the corresponding processing. Lathe is mainly used for processing axis, Plates, sleeves and other workpieces with a revolving surface are the most widely used types of machine tool manufacturing in the machine building and finishing plant.

![]()

1. CNC lathe machining precision, with a stable processing quality;

2. Multi-coordinate linkage can be processed to shape the complex parts;

3. CNC lathe machining parts change, generally only need to change the NC program, saving production preparation time;

4. CNC lathe processing itself, high precision, rigidity, the choice of favorable processing dosage, high productivity (usually for ordinary machine tools 3 to 5 times);

5. High degree of automation, can reduce labor intensity;

6. CNC lathe processing requirements of the operator's quality is higher, the technical requirements for maintenance personnel higher.