The optical fiber connector is an indispensable device for connecting various devices in an optical fiber communication system. Generally, the main optical characteristics of fiber optic connector products are insertion loss and return loss. In addition, physical characteristics such as the geometric parameters of the ferrule end face that affect product quality and reliability are also valued. The following is a brief introduction to the insertion and return loss of the connector based on the working principle of the optical fiber connector.

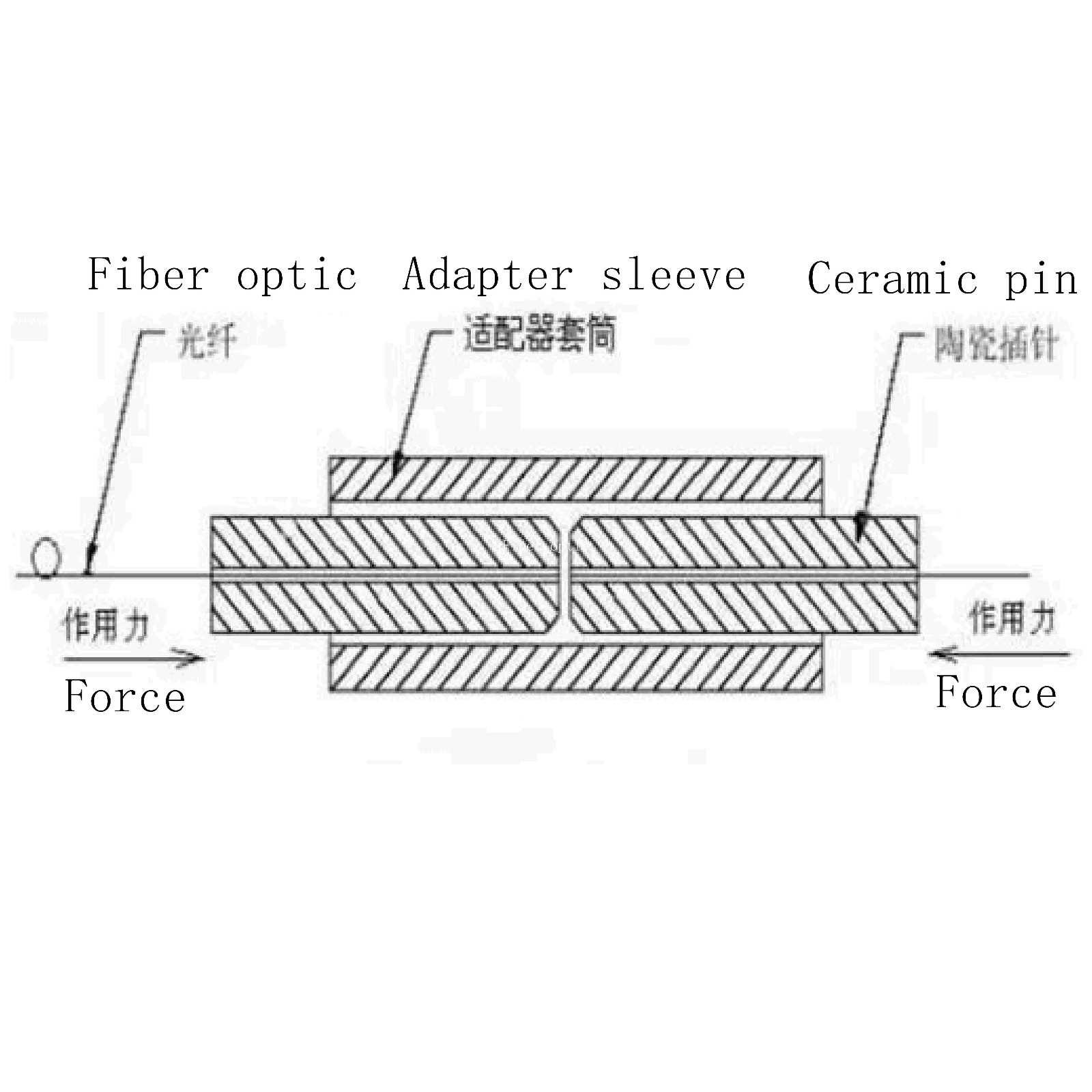

The optical fiber connector cannot be used alone. It must be mated with other connectors of the same type to form the connection of the optical path. At present, the more popular optical fiber connector assembly and docking method is: use epoxy resin heat curing agent to glue the optical fiber It is fixed in the ceramic pin hole and positioned by the adapter sleeve to realize the docking of the optical fiber. Insertion loss is caused by the lateral deviation between two consecutive optical fibers, the longitudinal gap in the fiber connector, and the quality of the end face.

It can be seen that ensuring the consistency of the two optical fiber cores in contact is the key to ensuring the excellent connection quality of the connector. It mainly depends on the physical properties of the optical fiber and the manufacturing accuracy of the connector pins, and the assembly of the connector. Processing accuracy, at the same time, the optical performance index of the optical fiber and the polishing quality of the pin end face have a direct impact on the optical performance and reliability of the connector. Insertion loss refers to the optical power attenuation caused by the connected connectors (that is, the relative reduction in the output power of the optical connector relative to the input power).

The insertion loss is mainly caused by the lateral deviation between two consecutive optical fibers. If the two fibers are aligned in a straight line and the lateral deviation is zero, the insertion loss caused by the two fibers is the smallest. However, in the actual docking process of the connector, this is unlikely to be achieved because of the misalignment between the fiber core and the fiber cladding, the misalignment between the fiber cladding and the inner hole of the pin, and the concentricity of the inner hole and outer diameter of the pin Degree errors, etc., will cause lateral deviation between fibers.

At the same time, the longitudinal gap and the quality of the end face in the optical fiber connector are also one of the factors causing the insertion loss. The UPC plug contact method commonly used in recent years can better solve the problem of longitudinal gap. In this way, the pins and the end faces of the fiber are spherically polished, so that the two pins that are opposite to each other are meshed together under the action of external force, deforming and flattening the apex of the mating fiber, forming a full fiber butt, and reducing Vertical clearance.

Return loss is a parameter used to measure the amount of retro-reflected light on the end face of a connector. The essence of the echo is the reflection of light. According to the principle of Fresnel reflection, Fresnel reflection occurs when light encounters two kinds of interfaces with different refractive indexes during transmission, causing signals in the optical path to overlap or interfere. In single-mode fiber systems with high transmission rates, especially CATV systems, the reflection phenomenon will cause the time lag of the transmission signal, delay the time when the signal reaches the user end, and cause the ghosting and sharpness of the image to decrease.

The UPC contact method of the connector joint reduces the gap between the connection end faces, in addition to reducing the insertion loss, and also reduces the reflection at the connection end face, increasing the return loss. For users such as CATV systems, the APC type The contact method is a better choice: Because the spherical normal of the ceramic ferrule end face of the APC connector has an angle with the axis of the fiber (generally 8 °), the light reflected from the end face leaks out without returning to the core. This greatly improves the return loss of the connector.

In summary, for excellent connector jumper manufacturers, in order to ensure the high quality of the product, three factors are essential. They are high-quality tight-fiber optical fiber cables, high-precision ceramic pins and Assembly parts, and excellent assembly processing technology.