In recent years, with the continuous development of medical industry in China, the demand for pharmaceutical market has increased sharply. However, the marking of medical packaging cannot do without the help of laser technology. Laser technology can be widely used in the packaging of various products in the pharmaceutical industry, such as carton, glass bottles, plastic bottles, capsules, thin-film and other materials for high-speed marking of expiration date, production batch number, date, bar code and other information. Whether in glass bottles or regarding stainless steel surgical instruments, whether it is a soft plastic film package or a corrugated carton, whether it is a single-piece package or a full case of medicine packaging, CYCJET laser marking solution can meet the marking requirements of different materials in the pharmaceutical industry.

Medical equipment pays high attention to safety and health, and has higher requirements for product marking. Only by choosing a good laser marking machine can we provide more protection for medical safety. CYCJET laser marking machine adopts a non-contact and pollution-free marking method, which is very suitable for pharmaceutical packaging marking.

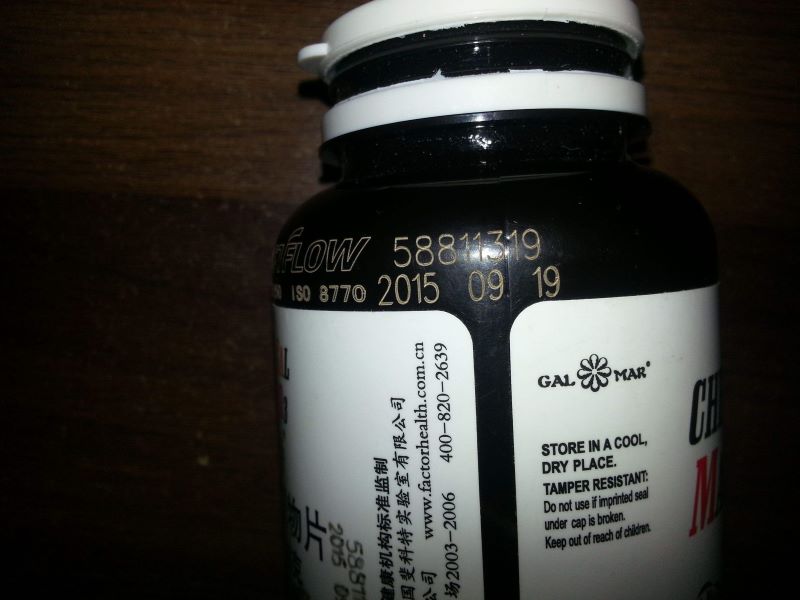

While using laser marking machine to mark on medical supplies, it has stable reliability and durability. The marked information is clear and intuitive with strong corrosion resistance. And it is not easy to be altered and erased, which guarantees the anti-counterfeiting of medical products. Moreover, from an economic point of view, the laser marking machine greatly improves the working efficiency, not only saves human resources, but also saves a lot of time. For example, the marking of conventional products generally only takes a few seconds. If using flying marking in production line, the speed will be faster.

In addition, the laser marking machine has Chinese and English operating menus, multiple language options, safe and effective, and easy to operate. It will also mark special logos (graphics, fonts, codes) on products or outer packaging to increase the cost of counterfeiters and prevent the circulation of fake and shoddy products. Therefore, in pharmaceutical companies, laser marking technology has increasingly become one of the most effective anti-counterfeiting methods. Customer management can also be carried out by marking different numbers and graphics to prevent cross-regional sales and channeling.

Moreover, marking bar codes on product packaging can speed up the classification and circulation of products, make the management between the production line and the warehouse more reasonable and scientific, and can also strengthen the monitoring of raw material consumption and the effective management of inventory.