The control system can logically process the program with the control code or other symbol instruction, decode it by the computer, so that the machine can perform the prescribed action, and cut the blank into semi-finished finished parts by cutting the tool. CNC processing out of the sample size, high strength, good toughness, low cost advantages, has become the preferred sample production of high strength, good toughness, low cost advantages, has become the first choice for sample production.

Our high seed precision CNC Milling and turning services are perfect for both one off prototypes and low mass volume production runs. We machined parts from many different plasticn and metal materials on our staste of the art machining finishes available CNC Machining is a very verssatile option. Fast, accurat and competitively priced whilst delivering superior surface finishes from a massive range of material options, CNC Machining is the backbone of INDUSTRI-MAN'S sevices.

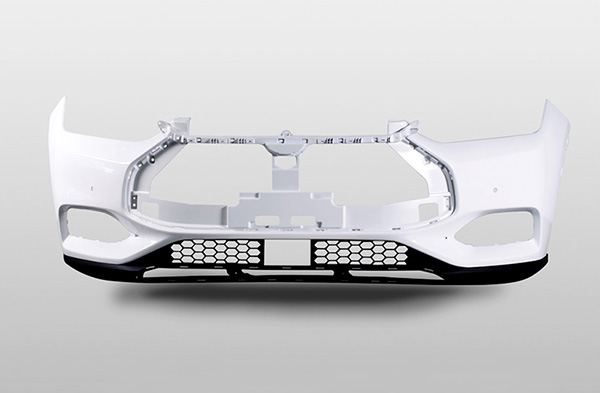

Car prototype production process

◆ Program editing:

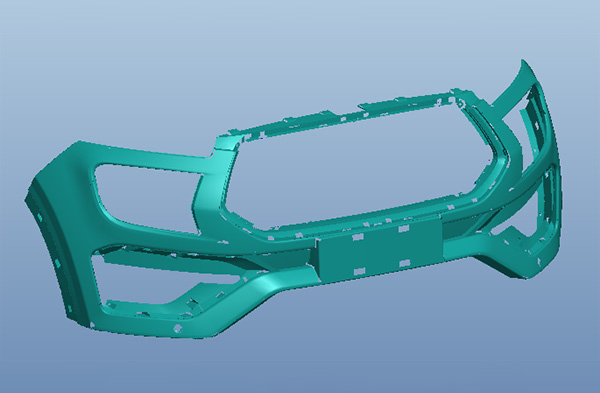

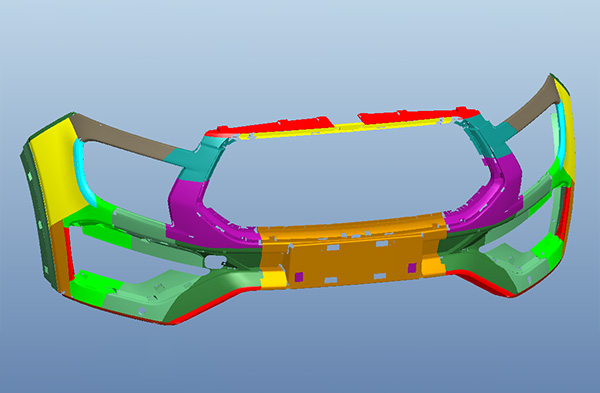

Program editing is divided into data analysis and tool path programming. When an order is to be produced, the engineer first analyzes the data, and according to the material, overall size, and process requirements of the part, the processing method and the part are properly selected.

After the data analysis is completed, the programmer will program the tool path for the part. We provide two programming softwares, UG and MasterCam.After the tool path is programmed, it is sent to the CNC machining center for CNC milling. The CNC operator processes the product according to the programming parameters.

◆ Assembly:

Assembly includes (manual clearing, splitting, product assembly, etc.)

◆ After the part completes the CNC machining

the manual master processes the parts according to the 3D data to meet the assembly requirements and tolerances.

◆ Polish:

After the assembly work is completed, the parts are polished to different degrees according to different processes (such as plating parts, transparent parts, high-gloss parts, etc.).

The coloring includes a series of post-treatment processes such as oil injection, water transfer printing, coating, electroplating, and laser engraving. After the parts are polished, the professional processes according to the process requirements.

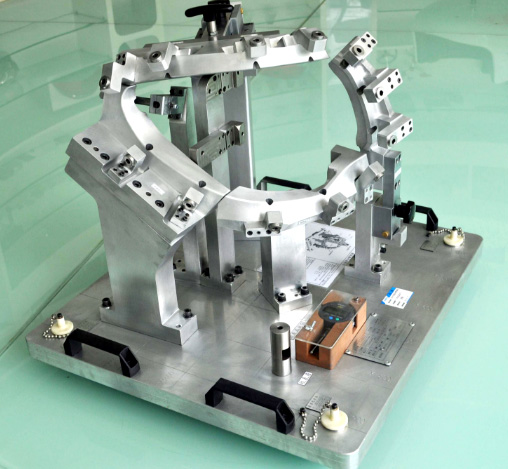

After all the process is finished, the product inspection and color proofing are carried out by the professional quality inspectors. The inspection tools include calipers, three coordinates, inspection tools and other professional inspection tools.