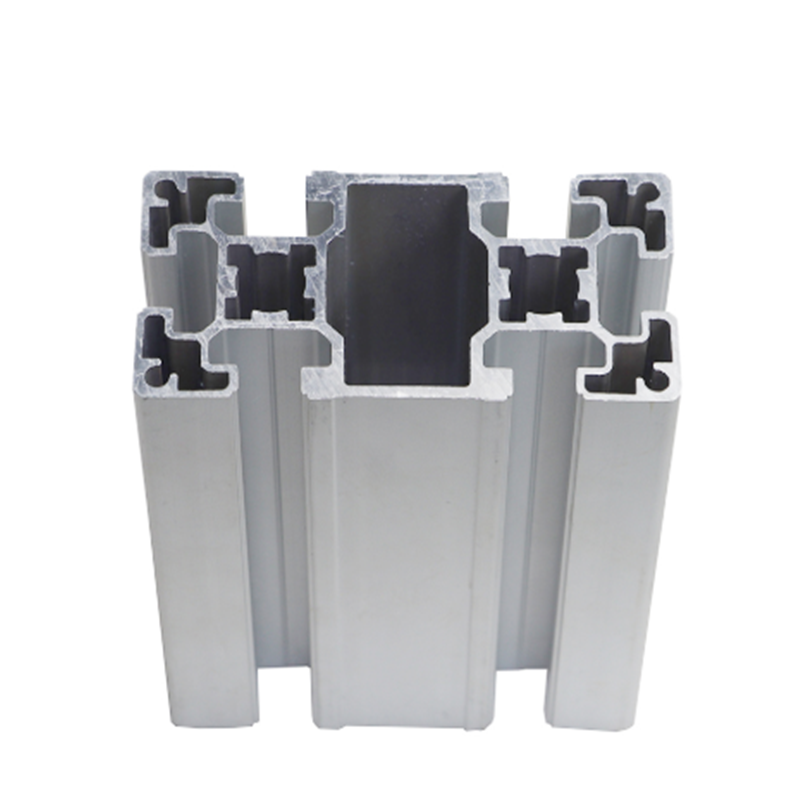

Industrial profiles

Industrial Aluminum English name meaning, Aluminum Profile System, alias: industrial Aluminum extrusion materials, industrial Aluminum Profile, industrial Aluminum is a kind of Aluminum as the main composition of the alloy material, Aluminum rods by hot melt extrusion to get different cross section shape of Aluminum material, but the different proportion of added alloy, the mechanical properties of the production of industrial Aluminum and different application fields.

Generally speaking, the field of application, industrial aluminum profile is in addition to the building doors and Windows, curtain walls, indoor and outdoor decoration and building structure with all aluminum profiles.

The characteristics of

On August 25, 2012, Counsellors' Office of the State Council and China Non-ferrous Metals Industry Association jointly held the high-level Forum on Promoting Aluminum Applications in Beijing.

At the forum, State Councilor and Secretary General Ma Kai stressed the need to actively promote the green development of the raw material industry represented by aluminum.

China's aluminum industry is experiencing a period of rapid development.

In 2011, China's primary aluminum output reached 17.786 million tons, 6 times that of 2010.

While the scale is expanding, problems such as shortage of resources and high consumption of energy are also becoming increasingly prominent.

For a long time, China's large non-ferrous resources mainly rely on imports.

In 2011, China's external dependence on aluminum reached 47%.

From the global point of view, mineral resources are limited and non-renewable, the recycling of non-ferrous metals has become an inevitable trend.

Aluminium is especially suitable for recycling because it is not chemically reactive.

In some developed countries, more than 50% of the total consumption of non-ferrous metals comes from recycling. In 2011, China's total production of recycled non-ferrous metals was 8.35 million tons, accounting for about 24% of the total consumption of non-ferrous metals.

With the introduction of a series of policies such as the Development And Promotion Plan for The Renewable Nonferrous Metal Industry and the Measures for the Import and Management of Solid Waste, nonferrous metals represented by aluminum began to explore new ways to meet the needs of energy conservation and emission reduction.

This means that the aluminum back of the iPad, once worn out and discarded, could re-enter people's lives as part of the aluminum Windows and doors.

Aluminium recycling will grow rapidly over the next decade

"Current primary aluminum production process is high energy consumption, whether indirect or direct, greenhouse gas emissions are relatively large.

The primary aluminum industry accounts for the largest share of emissions in the nonferrous industry."

Qiu Dingfan, academician of Chinese Academy of Sciences and professor of Beijing General Research Institute of Mining and Metallurgy, told reporters that the reduction of energy consumption and emission in the primary aluminum industry is a problem that requires a lot of efforts to be solved.

The energy consumption of primary aluminum in industrial production mainly comes from bauxite mining, alumina production, aluminum electrolysis and carbon anode production, among which the most energy consumption is aluminum electrolysis.

According to the International Primary Aluminium Association, aluminium electrolysis accounts for up to 64% of total energy consumption.

Aluminum electrolysis is also the largest source of carbon dioxide emissions, accounting for 79 percent of the total.

In order to save energy in the whole process of primary aluminum production, the key point is to save energy in the process of electrolytic aluminum.

As a matter of fact, government departments have begun to pay attention to the promotion of energy-saving electrolytic aluminum technology.

Miao Wei, minister of the Ministry of Industry and Information Technology, told reporters that low voltage and high efficiency aluminum electrolysis technologies, such as waste heat recovery and utilization of alumina production process and new cathode structure aluminum electrolysis cell, should be promoted to improve the level of industrial technology and equipment and reduce material consumption and energy consumption.

In recent ten years, the production of primary aluminum energy saving is obvious, especially the aluminum electrolysis unit power consumption decreased significantly.

According to the statistics of the Ministry of Industry and Information Technology, from 2000 to 2010, the output of primary aluminum showed a rapid growth trend, increasing 5-6 times.

Although carbon dioxide emissions have increased by a factor of four, the combined alternating current (AC) required for each ton of output of electrolytic aluminum has decreased significantly year by year.

"This is a remarkable result of technological progress in the aluminum industry," said Qiu Dingfan.

Compared with the electrolysis in primary aluminum production, the utilization cost of recycled aluminum is only 10% of the latter, and the energy consumption of recycled aluminum is only 5% of the former.

From the perspective of production cycle, as long as the raw material of recycled aluminum is sufficient, 8 hours will be able to turn waste miscellaneous aluminum into aluminum ingots, and electrolytic aluminum from mining to final production, the process is not to say, the time is longer.

Refining 1 ton of aluminum ingots only 1.2 tons of waste material, the yield is very considerable.

According to professional calculation, the electrolysis and smelting power consumption of 1 ton of 100% primary aluminum is 14,000 degrees.

Using 750 kg of primary aluminum and 250 kg of recycled aluminum production method, 10,800 degrees;

With 500 kg of primary aluminum and 500 kg of recycled aluminum, it only takes 7, 700 degrees.

If primary aluminum accounts for 35% and recycled aluminum accounts for 65% in the future, the energy consumption can be further reduced.

The recycling of aluminum has become an urgent problem in China.

In 2010, China's cumulative aluminum consumption exceeded 120 million tons. Since 2000, the industry has been engaged in large-scale aluminum production for 10 years.

The life cycle of aluminum is 20 to 30 years, which indicates that the recycling amount of aluminum will enter a stage of rapid growth in the next decade.

Europe's aluminium scrap is mainly exported to China

The premise of the aluminium cycle is the recycling of aluminium raw materials. In The past five years in Europe, more and more aluminium raw materials have been supplied by recycled materials, which have been regarded as an important part of the stable supply of aluminium raw materials.

The recycled material includes aluminum scrap, waste from the production process and waste after consumption.

According to recent statistics released by the European Aluminium Association (EAA), the European aluminium recycling industry is growing rapidly and improving in efficiency.

The aluminum packaging industry has become the focus, with the typical aluminum can recycling rate reaching 70 percent.

When the European Aluminium Association began measuring recycling rates in Europe 20 years ago, only about 30 per cent of the continent's cans would be recycled. By 2020, the rate is expected to reach 75 per cent.

However, the global circulation of aluminum will not be sufficient to meet the future growth of aluminum demand.

According to one statistic, even with an efficient recycling system in place over the next 10 years, waste aluminum recovery will only meet 35 to 40 percent of global aluminum demand.

This suggests that global demand for aluminium is growing much faster than the rate at which it is produced.

Even when process waste is included, the figure does not change much.

The European aluminium recycling industry is concerned about the export of aluminium scrap to countries where recycling laws are significantly below EU standards.

Europe's own aluminium recycling industry could suffer if too much of it is exported.

Still, Europe exported 739,000 tons of aluminum scrap to other countries in 2010, mostly to China.

Love wound international aluminum recycling director Herman han told reporters that "will remain in Europe and aluminum scrap processed into products actually very high, the eu has been a recycling society, strive to become in Europe to collect aluminum scrap is a big effort, but the recycling of waste aluminum to the outside of Europe, it is difficult to accept the fact."

The European aluminium scrap recycling industry has expressed the view that "alloy production using aluminium scrap is the first step in the value chain that is taking place in Europe".

The value system created by the aluminium cycle is already more secure in Europe. In 2011, the EU published a roadmap for efficient energy use in Europe and attempted to introduce a reward and punishment mechanism in 2015 to punish companies that fail to meet recycling targets.

The future is becoming clear

Qiu Was on a visit to an aluminum recycling company last year. He asked workers how to distinguish different kinds of aluminum and how to classify them.

Qiu Dingfan told the Economist that the classification of waste aluminum is crucial to achieve the aluminum cycle.

However, this pre-processing link, at present, is a large number of manual dependence.

In addition to low efficiency, it is difficult to classify accurately and effectively.

For example, since aluminum cannot be separated from alloy metal, casting alloy waste is not suitable for deforming alloy production.

Some aluminum castings and aluminum profiles, in the process of use consumption is very small, as long as not corroded, can almost reach 100% recovery, which mainly includes the construction of aluminum profiles, aluminum accessories, aluminum can lift box;

Besides the aluminum chemical containers used in chemical industry, there are also packaging materials for food and medicine. The reason is that it is difficult to peel aluminum from composite aluminum.

In order to achieve high separation of alloys, the optimization of sorting and processing equipment becomes the key to the aluminum cycle.

The policy ambiguity is the biggest bottleneck encountered by the recycled aluminum industry, and there are endless questions about the environmental protection of the recycled nonferrous metal industry.

In China, the development of waste aluminum recycling has been relatively slow for many years. Except for some enterprises in Hebei province, the scale of other enterprises is not large and the scale efficiency has not been achieved.

The average service life of aluminum products is about 20 years. However, in addition to the products that are forced to be scrapped in some countries, there are a large number of aluminum products that have extended their service life. In economically underdeveloped areas of China, many aluminum products far beyond the scrapped life are still in use, and even after they are retired, they are not recycled.

Despite the difficulties, the future of aluminium recycling is becoming clear.

At present, China's automobile industry "lightweight" trend, also makes the need for aluminum in the growing.

Bullet trains, subways and even moving trucks will see more and more recycled aluminum in the future.

By 2010, China's auto industry's demand for recycled aluminum reached more than 1 million tons.

Jungle group vice President Zhu Weizhong told reporters that the company has completed four all-aluminum trailer production lines, the annual production of trailer 10,000.

The automotive industry is just one direction in which waste aluminum is being recycled.

There will also be potential for the development of recycled aluminum in the construction sector.

Huang Qi, deputy secretary-general of China Construction Metal Structure Association, told reporters that the most heat in the building is lost through doors and Windows, about 50 percent.

Through the use of aluminum-wood composite window, aluminum-plastic composite window, coupled with low-E glass, in reducing the loss of heat will have a very good performance.

Under the promotion of the national building energy conservation policy, the demand of energy-saving aluminum doors and Windows and thermal insulation aluminum profiles will also become larger and larger.