The operation and monitoring of the CNC punch is all done in this CNC unit, which is the brain of the CNC punch.Compared with ordinary presses, CNC presses have the following characteristics:

1. High machining accuracy and stable machining quality.

2. Large processing format: 1.5m*5m processing format can be completed at one time.

3. Multi-coordinate linkage, can process complex shape parts can do shear forming.

4. Machining parts change, generally only need to change the numerical control program, can save production preparation time.

5. The precision of the punch itself is high, rigid, can choose the amount of processing, high productivity.

6. High degree of punch automation, can reduce labor intensity.

7. Simple operation, with certain basic computer knowledge training 2-3 days can start operation.

The programmed processing program is input into the CNC system, and the specific operation method is as follows:

1. Start the CNC machine tool: start the CNC machine tool through the mechanical operation panel, then input the processing program by the CRT/MDI panel, and then run the processing program.

1) start CNC machine operation

Machine start button ON

The program lock button OFF

2) edit operation

Select MDI mode or EDIT mode

Press (PRGRM) key

Input program name type program address, program number characters after press (INSRT) key.

(4) type program segment

Enter program segment number and operation instruction code, and then press (INPUT) key.

3) run the program

Program lock button ON

Select automatic cycle mode

2. Call the program operation: call has been stored in the numerical control system of the processing program, the specific method of operation through the mechanical operation panel to start the numerical control machine tool, then call the system processing program, and then run the program.

1) Start CNC machine operation

Machine start button ON

The program lock button OFF

2) Call program operation

Select MDI mode or EDIT mode

Press (PRGRM)

The calling program type program address, program number characters and then press (INPUT) key.

3) Run the program

Program lock button ON

Select automatic cycle mode

Press the auto cycle button

Motion axis:

X-axis: servo drive shaft that moves the workpiece along the direction perpendicular to the length of the bed.

Y axis: servo drive axis that moves the workpiece parallel to the length of the bed.

A axis: rotation axis of the mold selected by the rotary turret tool library.

C axis: rotation axis of mold automatic indexing, which can rotate the mold at any Angle.

1) Single punch: punch holes at a single time, including linear distribution, circular distribution, circular distribution and grid hole punching.

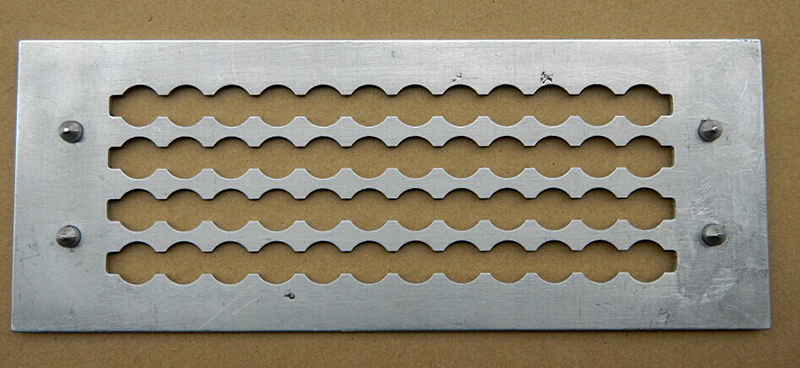

2) Continuous blanking in the same direction: long hole and edge cutting can be processed by using the method of partially overlapping processing of rectangular mold.

3) Multi-direction continuous blanking: the processing method of machining large holes with small molds.

4) nibbling: use small round die to make arc by continuous punching with small step distance.

5) Single-pass forming: the processing method of one-pass shallow drawing molding according to the mold shape.

6) Continuous forming: forming process with larger size than the mold, such as large-size shutter, rolling rib, rolling step and other processing methods.

7) Array forming: machining multiple pieces of the same or different workpieces on a large plate.

Station:

The universal thick turret mold is generally classified according to the hole size that the mold can process, which is convenient for the selection of the mold.Usually divided into A, B, C, D, E five file.

A(1/2 ") station: processing range Ø1.6 ~ & Oslash;The 12.7 mm

B(11/2 ") station: processing range Ø12.7 ~ & Oslash;The 31.7 mm

C(2 ") position: processing range Ø31.7 ~ & Oslash;The 50.8 mm

D(31/2 ") station: processing range Ø50.8 ~ & Oslash;The 88.9 mm

E(41/2 ") station: processing range Ø88.9 ~ & Oslash;The 114.3 mm