MBR technology, MBBR technology and FBBR technology are popularly used wastewater treatment technologies. They can be widely seen in industrial applications with high BOD content, such as food and beverage, dairy products, chemicals, leachate, etc. However, some people may not fully understand the three technologies or the differences among them. This blog will provide some basics to help people better understand MBR, MBBR and FBBR.

What Are MBR, MBBR, and FBBR?

MBR (Membrane Bioreactor)

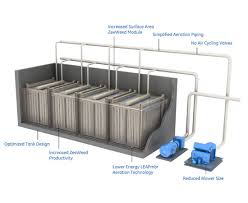

MBR stands for membrane bioreactor. It is a kind of wastewater treatment technology. The MBR wastewater treatment is a popular choice for municipal and industrial applications. The MBR process is a combination of membrane processes such as ultrafiltration and activated sludge process.

The membrane is mostly immersed in an activated sludge tank or a separate tank. Microorganisms consume organic matter in sewage by consuming oxygen. Since the membrane retains microorganisms and organics in the basin, higher MLSS concentrations are achieved.

High microbial content requires a huge amount of air. It needs not only oxygen but also sufficient mixed air to clean the membrane and limit scaling.

MBBR (Moving Bed Bioreactor)

MBBR is the brief form for moving bed bioreactor. It differs form MBR technology. It utilizes free-floating plastic fill media for attached biofilm growth. In order to keep the plastic filling medium in a suspended state, its density is close to that of water. Continuous aeration or mixing ensures good contact between the organics and the attached biofilm, thereby effectively removing BOD.

FBR (Fixed Bed Bioreactor)

FBBR means fixed bed bioreactor. The working principle of FBBR is very similar to that of MBBR, except that the biofilm is attached to a fixed block of filled media. Filled media blocks are typically arranged as submersible recyclable cages within a pond. Diffusion ventilation under the shroud unit provides the required oxygen for the biofilm and controls the scour of the filled media block.

Comparison Between MBR vs MBBR and FBBR

Let’s make a more clear comparison between MBR vs MBBR, and MBR vs FBBR.

MBR (Membrane Bioreactor)

Compared with other biological processes such as fixed beds, the sensitive MBR process is unable to handle overloading and is costly to operate and maintain. And the membrane cleaning requires chemicals. MBR plants utilize biodegradation and physical separation.

A screen for the elimination of grease and grit forms a portion of the upstream equipment to prevent membrane blockage.

An MBR system is a filtration device with a high concentration of bacteria (held inside the membrane), which is 4-5 times higher than FBBR and MBBR systems.

Depending on the size of the membrane pores, even bacteria can be separated from the water. Negative pressure is required to support the flow of wastewater through the membrane, which is an energy-intensive process and may be costly. In addition, it is necessary to backwash the membrane at set intervals and to replace the membrane occasionally. The system requires regular professional maintenance and upkeep.

The MBR system includes an upstream activated sludge buffer. Therefore, it produces less sludge than FBBR systems and MBBR systems, and no sludge sedimentation is required, which saves space.

MBR process chart:

Screening → Buffer → Activated Sludge Buffer → Filtration → Sludge Tank

MBBR (Moving Bed Bio Reactor)

As for MBBR technology, upstream screening is also required to remove grit and grease, but particles smaller than 3mm are allowed to pass, and even manual screening is possible. Compared to the MBR technology, the MBBR technology simply uses bacteria because of its breakdown of impurities.

The MBBR system contains particles (for example, made of UV-stabilized polyethylene) on which bacteria grow, forming biofilms on free-moving particles, thereby reducing impurities and thus sludge quality (but not as good as the MBR system). Sludge settlement is necessary after the bio-reactor at the kind of lamella technology. The advantage is that spare parts are cheaper and have a longer service life, so operating costs are lower than MBR process.

MBBR process chart:

Screening → Buffer → Activated Sludge By Moving Bed Media → Lamella → Sludge Tank

FBR (Fixed Bed Reactor)

The function of the FBBR system is similar to that of the MBBR system. The only difference is that the small particles used in the MBBR can move freely in the reactor, while the FBBR system has a fixed bed material (the substrate is made of UV stabilized polyethylene) where the biofilm grows. The operation and maintenance cost of the FBBR system is lower than any other wastewater treatment process.

This biological layer (microbial colony) converts organic pollutants contained in wastewater into sediments and minerals. This is primarily the work of aerobic organisms that require oxygen. An aeration system installed under the fixed bed material of the reactor provided sufficient air for the organisms. In addition, the current caused by the rising air results in a complete (horizontal and vertical) mixing of the contents of the tank due to the geometry of the fixed bed material used (characteristics of the mixing tank). The advantage of this system is that it is self-regulating and very effective. Although it is not effective as the MBR system, it has cheap, simple, and durable spare parts, thus ensuring lower operating costs than MBR process.

FBBR process chart:

Screening → Buffer → Activated Sludge By Fixed Bed Media → Lamella → Sludge Tank

The table below shows the pros and cons of all three systems:

MBR | MBBR | FBBR | |

Effluent water quality | Superior | Acceptable for irrigation | Acceptable for irrigation |

Overall costs | High | Medium | Low |

Energy consumption | High | Medium | Low |

Required space | Small | Large | Large |

Handling of an electrical shutdown | Up to 24 hours without problems | Afterwards bacteria will form bio-cakes | Good handling

|

Sensitivity to shifting of complex or toxic substances | Good | Medium | Medium |

Susceptibility to a grease leak | Very sensitive. Membrane needs to be cleaned well/replaced | Very sensitive | Leaked oil will float upwards and is easy to remove. |