CONTROL THEORY OF NEAR-FIELD ELECTROSPINNING

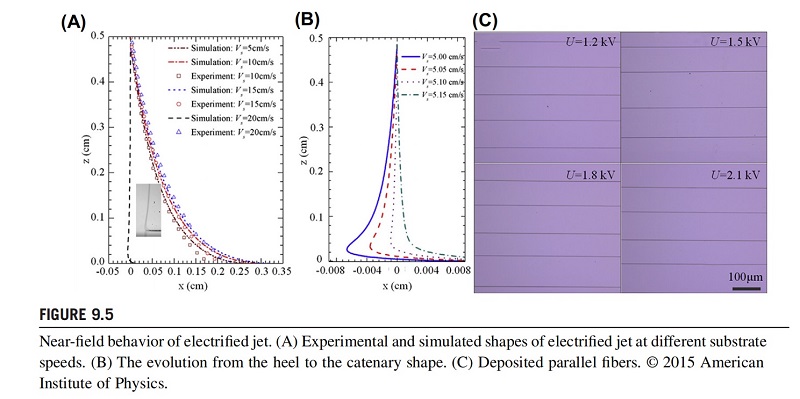

To promote the deposition precision of NFES nanofibers, investigating the controlling theory of charged jets is necessary, and some simulation models have been established. In 2010, Zheng et al. built a computational model based on Maxwell viscoelastic theory to study the deposition behavior of a single coiled nanofiber on a silicon substrate made by NFES. According to the experiment and simulation results, the moving speed of the collector is the key controlling parameter to influence the deposition morphology of the nanofiber. With various collector moving speeds, nanofibers with different structures, such as straight lines, waves, single-circle coils, and multicircle coils, can be gained. The imbalance in the charge repulsive force is the main factor in the formation of coiled spiral nanofibers, so the effect of collector conductivity has been investigated as well. With increasing collector conductivity, the distance between adjacent nanofiber coils and the diameter of the multicircle nanofiber zone decrease, which is in good agreement with the experimental results. Bu et al. investigated the dynamics and shapes of electrified jets deposited onto a moving substrate in NFES. The jet buckles to a “heel” when the speed is lower than 5 cm/s. When the speed increases, a strong pulling force will come into being, which leads to a larger deflection distance and makes the jet draw to a stable catenary shape, as illustrated in Fig. 9.5A and B. From the simulation results, the precise deposition control of NFES nanofiber patterns lies in the selection of substrate speed. Fig. 9.5C shows that under the drag force from the moving collector, the jet can be stretched into a tightened state. Zheng et al. established a model to study the deposition behavior of tightened jets. The difference between jet ejection velocity and collector velocity plays an important role in the motion and deposition behaviors of a charged jet during the stretching process. When the collector velocity is low, the jet will be in a relaxed state and there will be no deviation, so that the collector velocity has no effect on the moving velocity of the jet. However, when the collector velocity is high enough, the jet will turn to a tightened state and the moving velocity of the jet will be increased, which is beneficial to the integration fabrication of fine nanofibers.