The wet and dry rubbing color fastness test is mainly used to test the color fastness of textiles. It is widely used in the textile industry. At present, the textile instrument industry has different types of wet and dry rubbing color fastness test instruments, and the common ones are electric dry and wet rubbing colors. Fastness tester and manual dry and wet rubbing color fastness tester, this paper mainly introduces the Electronic Crockmeter as an example.

Application:

Crockmeter is used to test the dry/wet friction-type frictional decolorization test of leather, and is also suitable for the color fastness test of colored fabrics such as cotton, chemical fiber and blended fabric.

Product details:

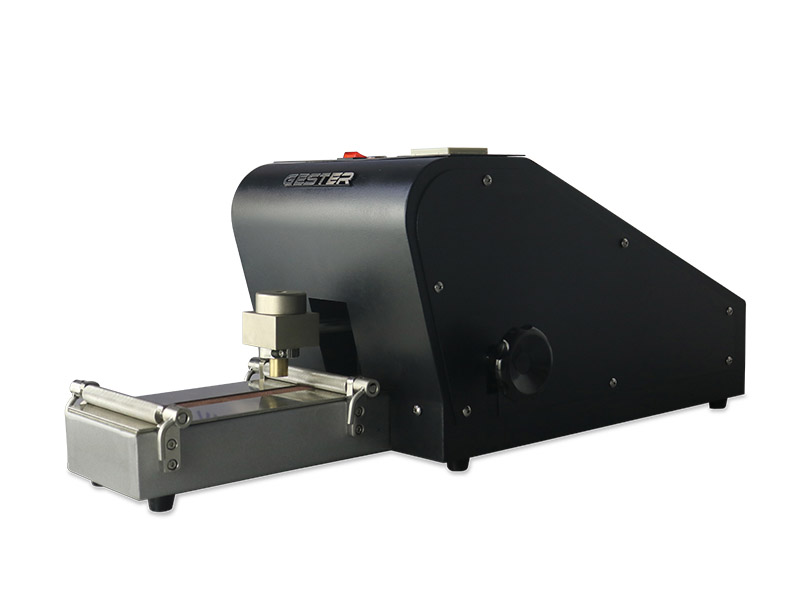

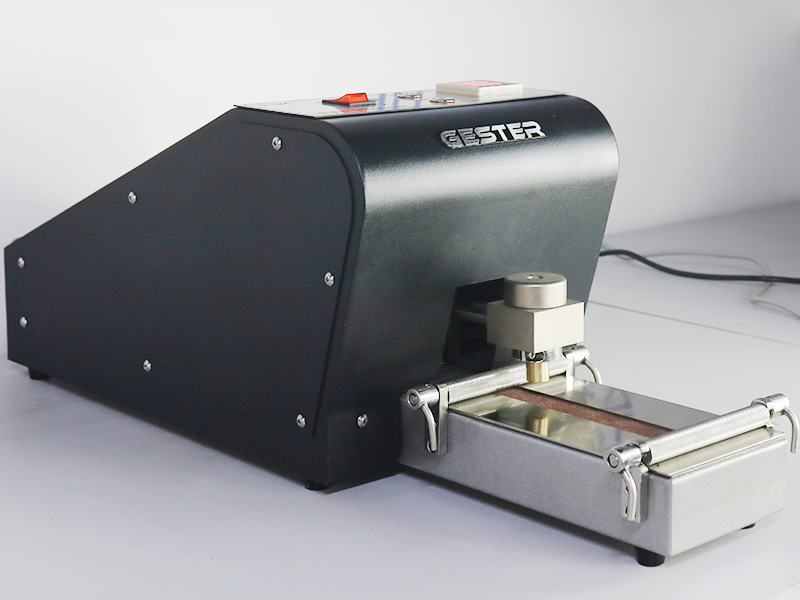

AATCC Standards Electronic Crockmeter is used to determine color fastness, which may be transferred to other surfaces due to friction. The machine is named after the term "friction discoloration", which refers to the transfer of pigments or other substances from the test piece to the dry/wet cloth that rubs against it.

Crock meter comprises a bottom plate with a sample to be tested fixed thereon. The test head can be moved back and forth along the sample. The standard friction cloth is mounted on the test head, and the movement of the test head is controlled by the crankshaft transmission, and the test head has a certain load. The dyed fabric is typically tested using a white standard rubbing cloth.

Electronic crockmeter features:

· Metal box, High-temperature baking coating, easy maintenance.

· Electric motor, fitted with a pre-determined electronic counter for strokes up to 9999, experiment complete successfully, automatic stop.

一、Dry rubbing fastness test.

1. Friction direction Along the length direction of the sample, the friction sandpaper is placed on the base of the friction device along the length direction, and the test sample is placed on the friction sandpaper.

2. Place the sample holder on the sample to prevent the sample from slipping.

3. Attach a square friction white cloth to the downward facing friction head. The warp direction of the small white cloth is parallel to the rubbing direction. Use a special metal collar to cover the small white cloth. Note that the metal collar position should not be too low. This will drag the test specimen.

4. Put down the friction test head on the sample. The starting position is to place the friction head in the forward and backward position, and shake the handle back and forth at a speed of one round trip per second, so that the friction head reciprocates a total of 20 times in the sample. Electric friction tester, please set and start the instrument 10 back and forth. For other round-trip requirements, please refer to their requirements.

5. Remove the square friction white cloth, adjust the humidity according to the standard (AATCC) requirements, and then compare the staining level against the stained gray card according to the standard method. For napping, raising, and sanding samples, once some loose fibers are applied to the rubbing white cloth, the rating will be affected. Before rating, use tape paper by gently pressing on the rubbing white cloth to remove the unrelated short fibers.

二、wet rubbing fastness

1. Thoroughly wet the rubbed white cloth in distilled water.

2. Before the test, use any easy-to-operate method, such as sandwiching the rubbing cloth between the filter papers and rolling with a rolling mill to control the moisture content of the rubbing cloth to 65% ± 5%. This moisture content is calculated based on the humidity of the dry rubbing cloth under standard atmospheric conditions (temperature 21 ° C, relative humidity 65%).

3. Perform friction test according to the above dry friction method.