On August 8th, 2017, Prof. Yu Demei from Xi'an Jiaotong University teamed up with Prof. Zhang Lifeng from North Carolina A&M State University to publish an online titled Electrospun Nanofiber: Emerging Reinforcing Filler in Polymer Matrix Composite Materials in Progress in Polymer Science. Progress in Polymer Science mainly invites authoritative scientists in the field of polymer research to write a review, reviewing the research frontiers, hotspots, status quo and future of the field in the world. Only about 45 articles are published each year, which has an important influence in the academic world. The journal has an impact factor of 25.766 in 2016 and a five-year average impact factor of 32.367.

Polymer Matrix Composite (PMC), especially Fiber Reinforced Polymer (FRP), has the advantages of light weight, high strength and excellent processability, etc. It is widely used in aerospace, electronic and electrical, transportation, construction, machinery manufacturing and other fields.

Polymer-based nanocomposites are typical examples and research frontiers in the field of PMC in recent years. Their development relies on the preparation of nanofillers, such as that the successful preparation of carbon nanotubes (CNTs) and Graphene, respectively led to the boom and leapfrog development of the corresponding PMC research. Since the 1990s, electrospinning has received much attention as a technology for preparing continuous nanofibers. Although electrospinning nanofibers are currently used primarily in separation, catalysis, sensors, energy conversion and storage, they have the combined advantages of reinforcing fillers with other common nanoscale fillers, such as continuity, structure/diameter controllable, diversified materials, orientation/self-assembly and large-scale production capacity are expected to have great potential in the development of next-generation PMCs.

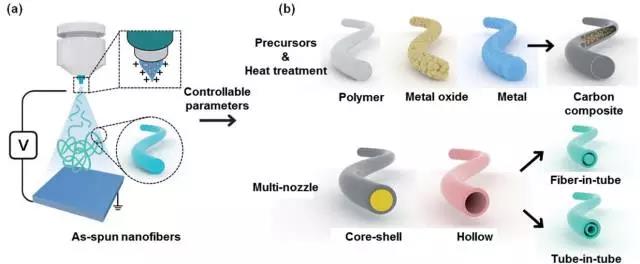

Figure 1 Schematic diagram of electrospinning device (a) and its electrospinning nanofiber (b) [1]

This paper is based on decades of research work in the field of polymer micro/nano composites and electrospinning and polymer matrix composites by Prof. Demei and Zhang Lifeng. Electrospinning nanofibers are used as polymer matrix composites. The advantages of the emerging reinforcing fillers are the entry points. The development of electrospinning nanofiber reinforced polymer matrix composites is traced. The electrospinning nanofibers are prepared in the preparation of polymer nanocomposites and polymer composite laminates. Recent advances in (Polymer composite laminate) and its potential applications in structural materials, biomedical materials and dental materials, on nanofiber parameters (eg diameter, aspect ratio, degree of orientation, fill, structure, post-treatment, fiber), layer thickness, etc., nanofiber-polymer matrix interface interaction, composite material preparation process and other factors have been discussed and elaborated on the mechanical properties of polymer composites, and reviewed and forecasted the current challenges and future challenges and the direction of development in this field.

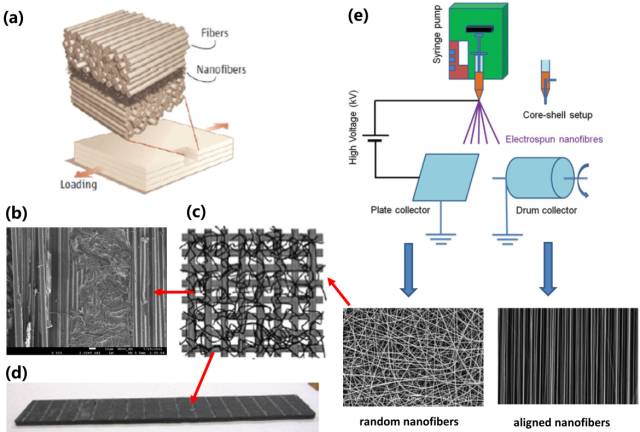

Figure 2 Polymer composite laminate based on electrospinning nanofibers [2,3]

Prof. Yu Demei has long been engaged in research on polymer-based micro/nano composites, functional polymers, and organic/inorganic hybrid materials. In recent years, the controllable preparation, structural design, interface control and intermediation of the above materials have been introduced. A lot of work has been done in high-performance fields such as electricity, electrical conduction, heat conduction, mechanics, and micro-nano structure manufacturing, and a series of important progress has been made. The relative results were published in prestigious international journals, such as Advanced Energy Materials, Advanced Materials, Energy & Environmental Science, Journal of Materials Chemistry A, Carbon, Composites Science and Technology, Composites Part A;Soft Matter, Langmuir, The Journal of Physical Chemistry C, Nanotechnology, Materials & Design, Synthetic Metals, Reactive and Functional Polymers.

The author of the paper is Prof. Yu Demei from Xi'an Jiaotong University and Prof. Zhang Lifeng from North Carolina Agricultural University. The first author is Wang Guolong, a doctoral student at Xi'an Jiaotong University (teacher Yu Demei).

The above work has been approved by the National 973 Program Subproject (No. 2009CB 724202), the National Natural Science Foundation Project (No. 51473133), the Shanxi Provincial International Science and Technology Cooperation and Exchange Program Key Project (No. 2015KW-016), and Xi'an Jiaotong University- Support from the Academic Exchange Program of North Carolina Rural State University.

__________________________________________________

Paper link:

http://www.sciencedirect.com/science/article/pii/S0079670017300758

References:

[1] Ji-Won Jung et al. J. Mater. Chem. A, 2016, 4:703.

[2] Xiang-Fa Wu et al. J. Appl. Polym. Sci., 2013, 129:1381-1393

[3] Shengjie Peng et al.Chem. Soc. Rev., 2016, 45, 1225-1241